Inlaid brake pad and manufacturing method thereof

A production method and technology of brake pads, applied in the field of brake pads, can solve the problems of pollution, single shape of brake pads, and inability to attract customers' attention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

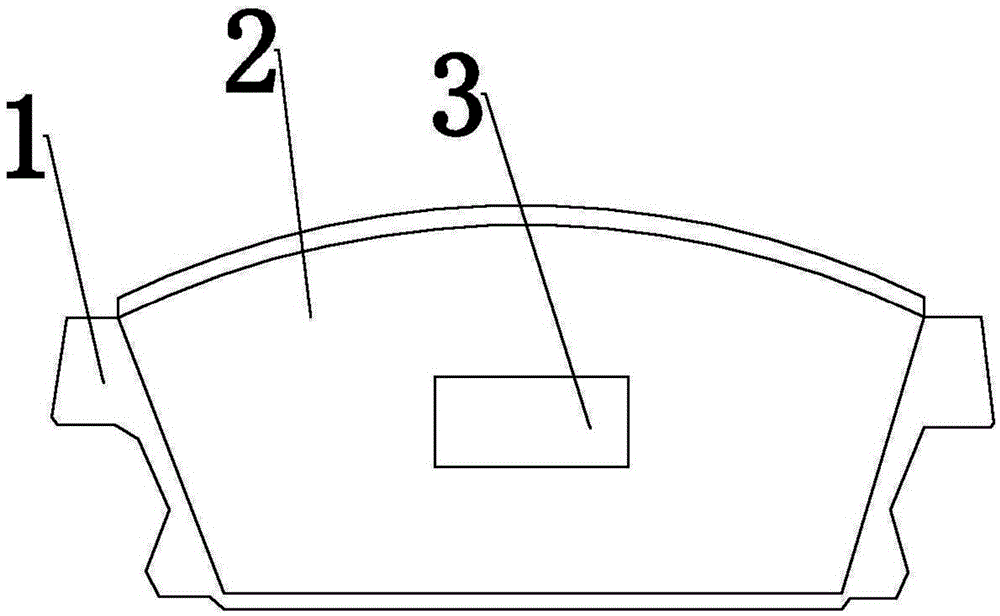

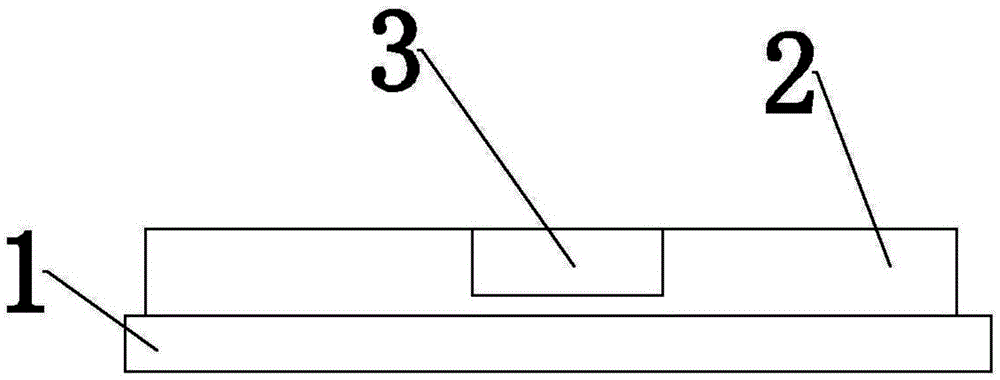

[0071] Such as figure 1 and figure 2 An inlaid brake pad is shown, which includes a steel back 1 and a friction material block 2, one side of the friction material block 2 is bonded to the steel back 1, and the other side of the friction material block 2 is inlaid with rice straw fiber wear-resistant Block 3.

[0072] The rice and wheat straw fiber wear-resistant block includes the following components in parts by weight:

[0073] 25 parts of rice straw composite fiber;

[0074] 6 parts of phenolic modified resin;

[0075] 10 parts of carbon fiber;

[0076] Potassium titanate whiskers 5 parts;

[0077] 0.5 parts of pyrite;

[0078] 3 parts of molybdenum disulfide;

[0079] 1 part of aluminum oxide;

[0080] 4.5 parts of 40 mesh brass powder;

[0081] 15 parts of rice straw activated carbon powder;

[0082] 5 parts of aramid fiber;

[0083] 25 parts of rice straw activated carbon powder artificial graphite.

Embodiment 2

[0085] How to make mosaic brake pads:

[0086] Component preparation: collect newly harvested or one-year rice straw, remove moldy and rotten rice straw, and clean the soil and impurities on the straw; the cleaned rice straw is exposed to the sun or dried; when drying, The drying temperature is 45°C-55°C; exposure or drying until the moisture content of rice straw is 9%-13%;

[0087] Preparation of rice-wheat straw composite fiber: Cut the dried rice-wheat straw into small pieces of 5-20 cm; immerse the cut straw in the slurry for 10 days, take it out and dry it, and then keep the temperature at 60°C for 12 hours Drying; the slurry contains the following components: 2 parts of resin, 4 parts of alcohol, 3 parts of natural rubber, 0.5 part of sulfur, and 0.5 part of anti-aging agent; the dried rice and wheat straw is thrown and cut in a slicer, first The speed is 1000 rpm, and the cutting is for 30 minutes; the second speed is 1500 rpm, and the cutting is for 30 minutes; the f...

Embodiment 3

[0112] Component preparation and friction material block are the same as in Example 2

[0113] A method for manufacturing an inlaid brake pad, comprising the following steps:

[0114] Step 1) Mixing, weigh the following components by weight, and mix evenly to obtain the mixture:

[0115] 25 parts of rice straw composite fiber;

[0116] 6 parts of phenolic modified resin;

[0117] 10 parts of carbon fiber;

[0118] Potassium titanate whiskers 5 parts;

[0119] 0.5 parts of pyrite;

[0120] 3 parts of molybdenum disulfide;

[0121] 1 part of aluminum oxide;

[0122] 4.5 parts of 40 mesh brass powder;

[0123] 15 parts of rice straw activated carbon powder;

[0124] 5 parts of aramid fiber;

[0125] 25 parts of rice straw activated carbon powder artificial graphite;

[0126] Step 2) Weighing, weighing the mixture according to demand;

[0127] Step 3) Hot pressing, pour the mixture into the mold, use a press to carry out hot pressing under the conditions of 150-160 °C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com