Carbon fiber electric heating plate floor heating structure

A carbon fiber heating wire and carbon fiber technology, applied in the field of heating and heating, can solve the problems of heat dissipation, unfavorable control, and high cost, and achieve the effects of promoting blood circulation, slowing down metabolism, and balancing pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

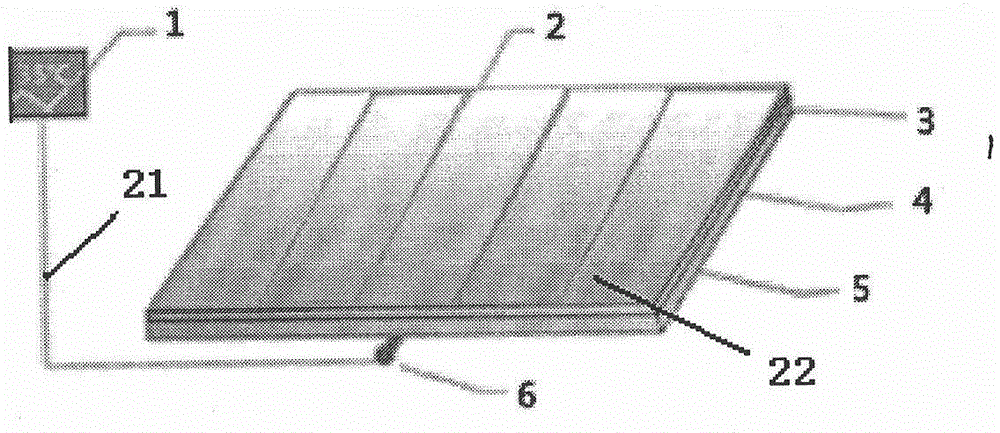

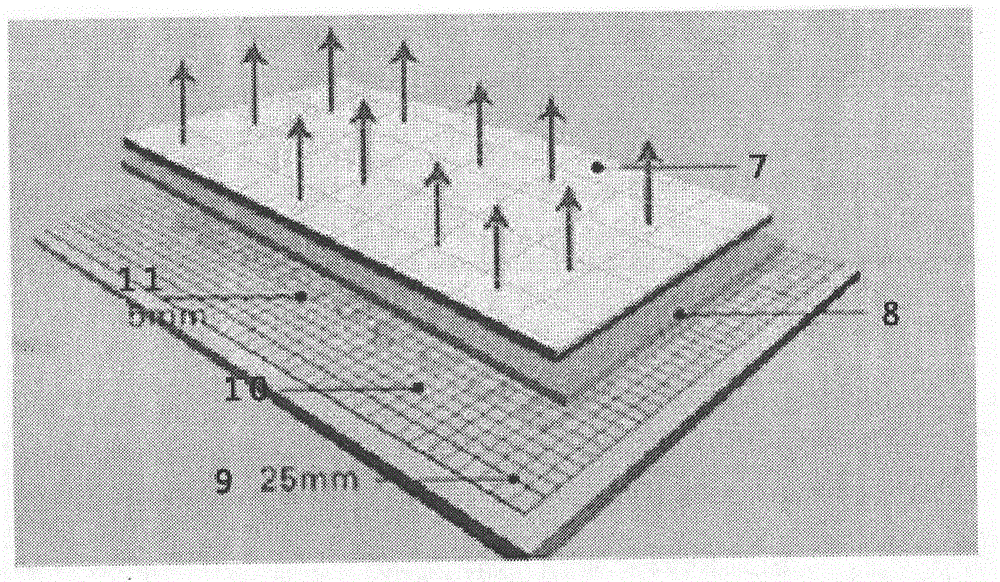

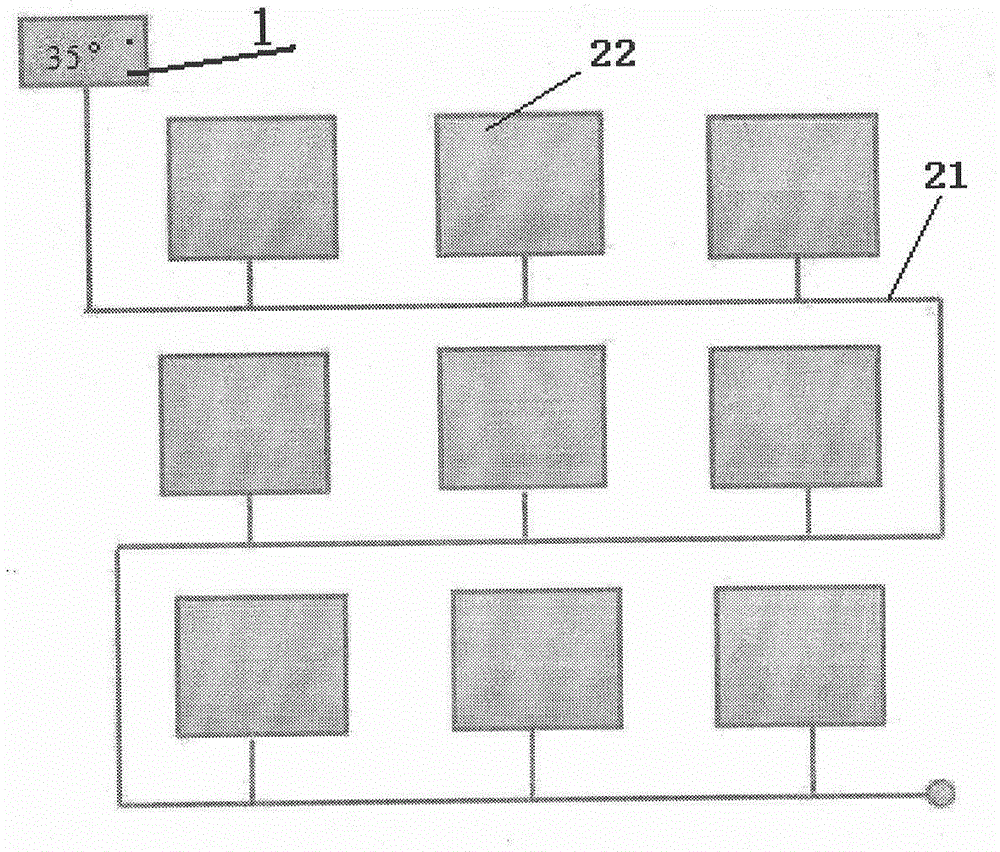

[0041] figure 1 It is a schematic diagram of the overall structure of the heating plate of the carbon fiber electric heating plate floor heating structure of the present invention. figure 2 It is a schematic diagram of the single board structure of the heating board. As can be seen from the figure, a carbon fiber electric heating plate floor heating structure includes an intelligent controller 1, a power connection line 21, a waterproof joint 6, a floor layer 7, a cement layer 8, and a heating element 3 equipped with a carbon fiber heating wire; wherein, From top to bottom, the floor layer 7 is bonded to the cement layer 8; the cement layer 8 is bonded to the heating element 3 equipped with carbon fiber heating wire; the heating element 3 equipped with carbon fiber heating wire includes a silk screen layer 2, Carbon fiber heating wire 12, insulation layer 4, reflective layer 5; under the heating element 3, there is an inherent wire mesh layer 2 for protection, and the wire m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com