Drying system with combination of hot air drying and cold air drying

A technology of cold air drying and drying system, which is applied in solar heating systems, dryers for static materials, drying solid materials, etc., can solve the problems of environmental pollution, high cost, and low thermal efficiency, and achieve energy saving, ensure drying quality, and improve The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

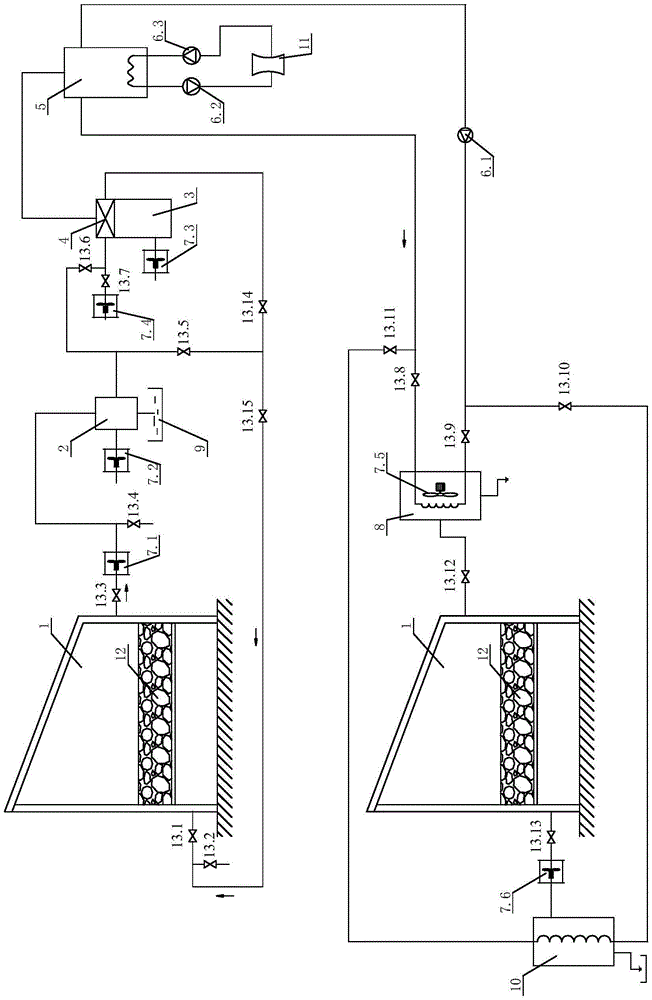

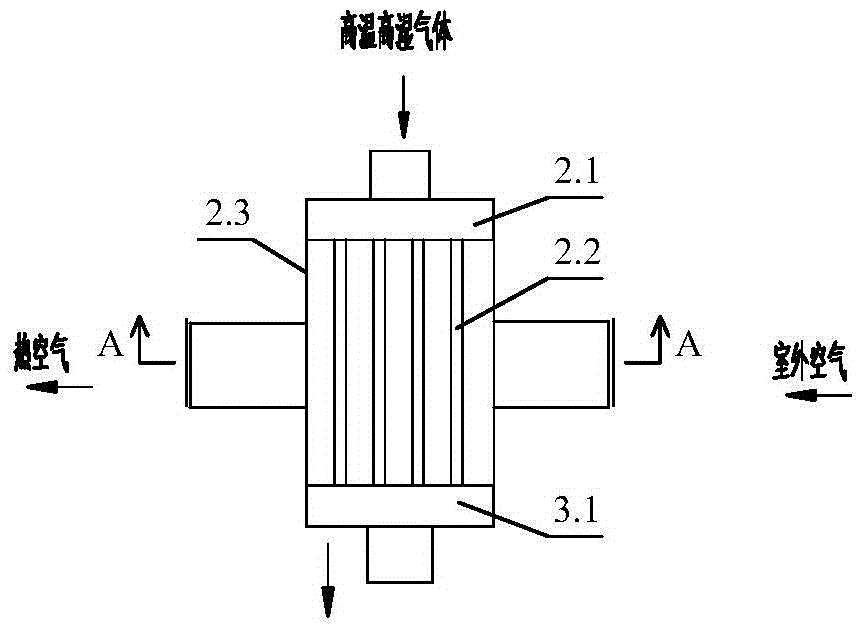

[0026] like figure 1 As shown, a drying system combining hot air and cold air drying of the present invention includes a solar greenhouse 1, an air condenser 2, a water bath dust collector 9, a heat source, an air heater 4, a flue gas refrigeration device, an air cooler 8, a cooling The tower 11, the dehydrator 10, the pipes connecting each device and the valves 13.1-13.15 and fans 7.1-7.6 arranged on the pipes. details as follows:

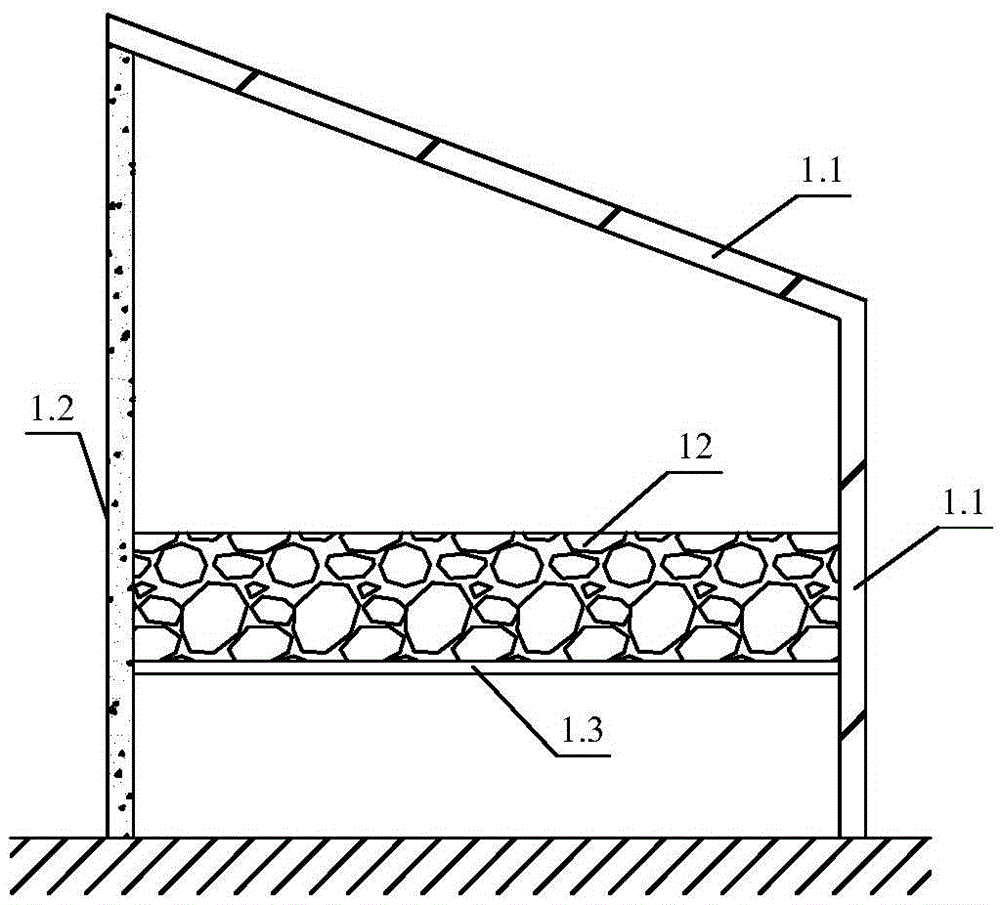

[0027] like figure 2 As shown, the orientation of solar greenhouse 1 is different according to the different regions. In principle, its front should face the direction with the strongest solar radiation. In the northern hemisphere, it is generally facing south. The building structure of the solar greenhouse 1 is a frame structure, and the top surface and the east, west, and south sun-receiving surfaces are compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com