High-ammonia nitrogen high-salt wastewater resourceful treatment method

A treatment method, high-salt wastewater technology, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of inability to realize energy reuse, blockage of stripping distillation tower, high equipment investment, etc. Achieve good economic benefits, reduce equipment costs, and simplify equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

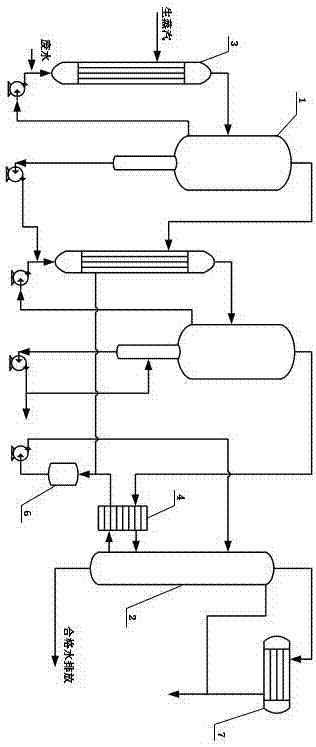

[0034] An example of the application of single-effect evaporation and stripping distillation column coupling treatment of high-ammonia nitrogen and high-salt wastewater.

[0035] Wastewater 1 enters the single-effect forced circulation evaporation system for evaporation and crystallization, crystallized salt 6 is discharged from the system through centrifugal separation, raw steam 2 (about 0.4-0.5MPa) heats the wastewater in the evaporator, and the evaporated secondary steam 3 (about 0.3MPa ) as the heat source of the stripping and rectifying system enters the reboiler, the condensed water 4 is dilute ammonia water, enters the condensed water tank, and then pumps into the stripping and rectifying system for deamination, after multi-stage vapor-liquid balance, the concentration at the top of the tower is High-purity concentrated ammonia water 8 higher than 18%, the concentration of ammonia nitrogen in the effluent of the tower kettle meets the requirements (for example, less tha...

Embodiment 2

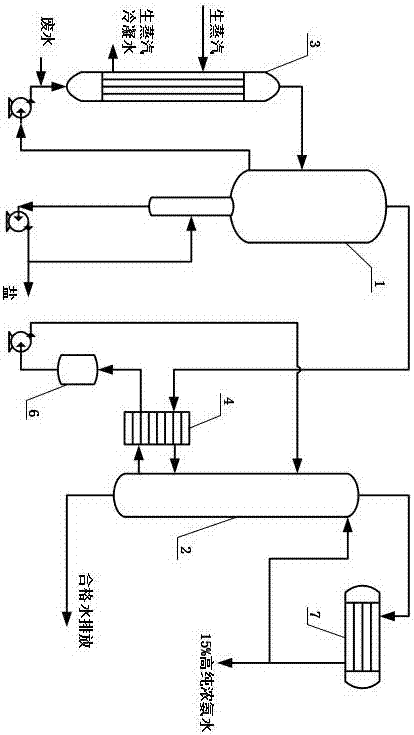

[0037] An example of the application of a three-effect evaporator coupled with a stripping distillation column to treat high-ammonia nitrogen and high-salt wastewater.

[0038] Wastewater 1 first enters the first-effect falling film evaporator for evaporation and concentration, then the first-effect effluent 2 enters the second-effect forced circulation evaporator, and the second-effect effluent 3 enters the third-effect forced circulation evaporator. Evaporated and dissolved by steam condensed water, the waste water is concentrated step by step until supersaturated and crystallized, and the crystallized salt 4 is separated by a centrifuge and discharged out of the system.

[0039] The raw steam 5 (about 0.7MPa) enters the shell side of the first-effect evaporator, and the evaporated mixed steam 6 (about 0.5MPa) of water vapor and ammonia vapor is used as the heat source of the second-effect evaporator, and the condensed water 7 of the second-effect evaporator enters Three-eff...

Embodiment 3

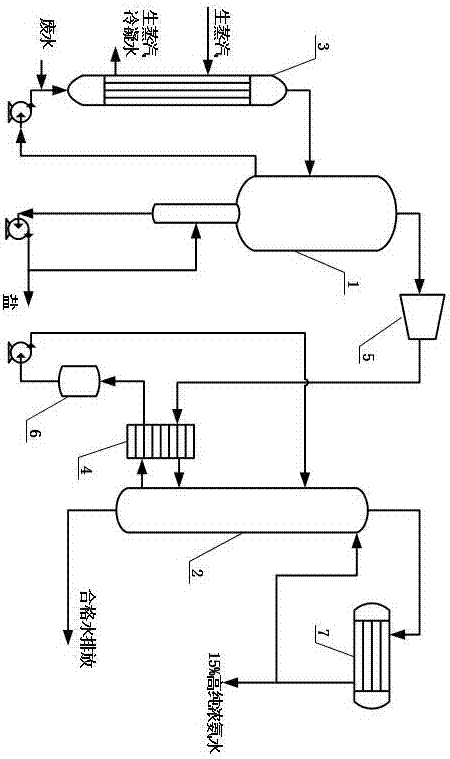

[0042] An example of the application of MVR coupled with stripping and rectifying towers to treat high-ammonia nitrogen and high-salt wastewater.

[0043] Wastewater 1 enters the forced circulation evaporation system to be evaporated and concentrated, and crystallized salt 6 is obtained after supersaturation, and is discharged from the system after centrifugation.

[0044] Raw steam 2 (about 0.3MPa) heats the evaporation system, and the condensed water is discharged out of the system. The secondary steam 3 (about 0.1MPa) generated by the evaporation system enters the steam compressor, and the enthalpy of the compressed secondary steam 4 increases (about 0.3MPa), and then enters the reboiler as a heat source for the stripping and rectifying system, and is condensed to obtain The dilute ammonia water 5 enters the condensed water tank, and the condensed water enters the stripping rectification system for deammonization treatment. After multi-stage vapor-liquid balance, the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com