Method used for rapid evaluation of stain resistance of coated plates, and special standard pollutant

A technology of contamination and contamination resistance, applied in the field of coatings, can solve the problems of poor contamination resistance data consistency, poor contamination resistance, and inability to evaluate real performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Standard Pollutant Preparation

[0086] The following are pollutant samples taken from Chengdu, Shanghai, Langfang, and Guangzhou and the configuration ash specified in GB9780-2005. SEM-EDX elemental analysis of the samples was carried out and the results are as follows:

[0087] Table 2 SEM-EDX analysis results

[0088]

[0089] According to the analysis of SEM-EDX, the element range of the pollutants is set as follows, among which, the C element must be derived from the C element in the organic matter.

[0090] Table 3 Pollutant element distribution (at%)

[0091]

[0092] According to the elements of the set pollutants, the standard pollutants in Table 4 below are produced.

[0093] Table 4 Elemental Composition and Distribution of Standard Pollutants (at%)

[0094]

[0095] Among them, the composition of material A is shown in the following table 5, wherein, B44 is Rohm and Haas Company acrylic resin product model B44, NaCl, KCl, MgO and TiO 2 Use analy...

Embodiment 2

[0107] experiment method

[0108] 1. Test board

[0109] Material: 3 pieces of non-asbestos cement board (one piece is reserved)

[0110] Size: 4×150mm×70mm

[0111] pH value: The substrate needs to be de-alkalized first, and soaking treatment is required. The pH value of the solution after soaking is required to be between 7-8.

[0112] 2. Production of test samples (test substrates)

[0113] Paint according to the standard paint system as follows:

[0114] Flat coating: one primer + two top coats.

[0115] Metallic paint: one primer + one metallic paint + one finish varnish;

[0116] Coating method: flat coating with brush, each brush 140g / m 2 Prepare special effects and paint panels according to standard coating methods

[0117] Surface coating color: white, metallic paint with natural color;

[0118] Maintenance: dry at room temperature for seven days

[0119] 3. Test

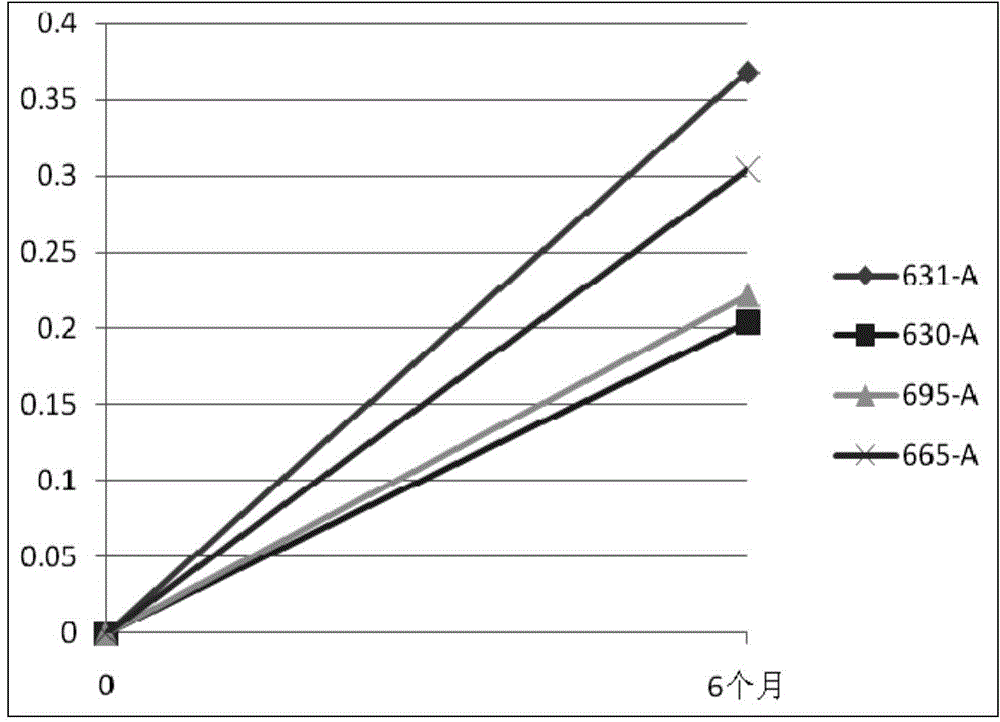

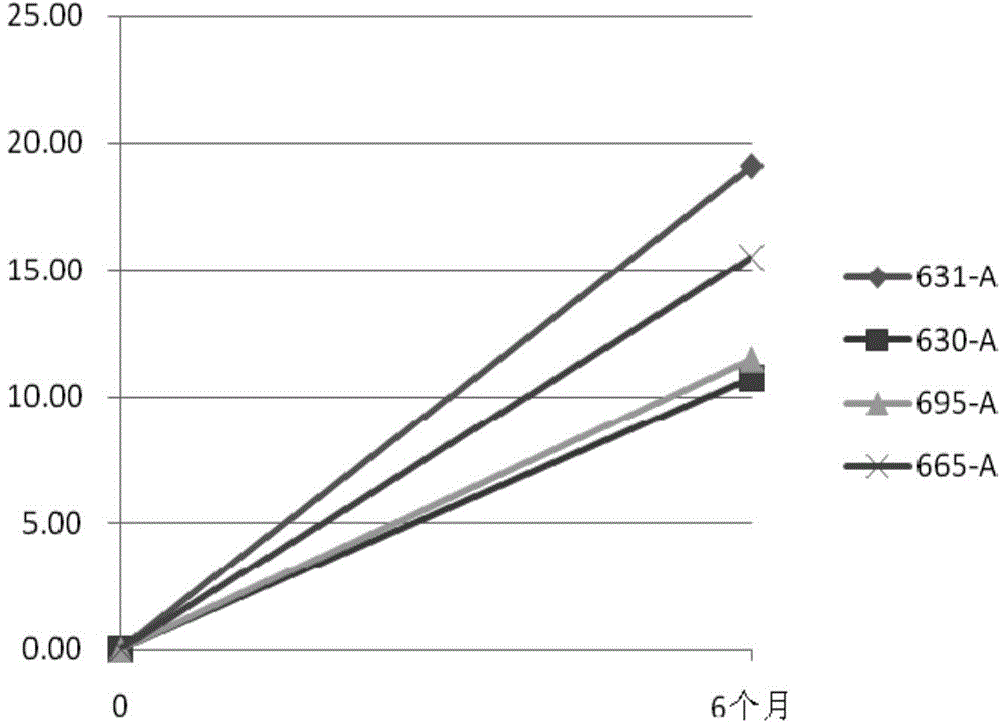

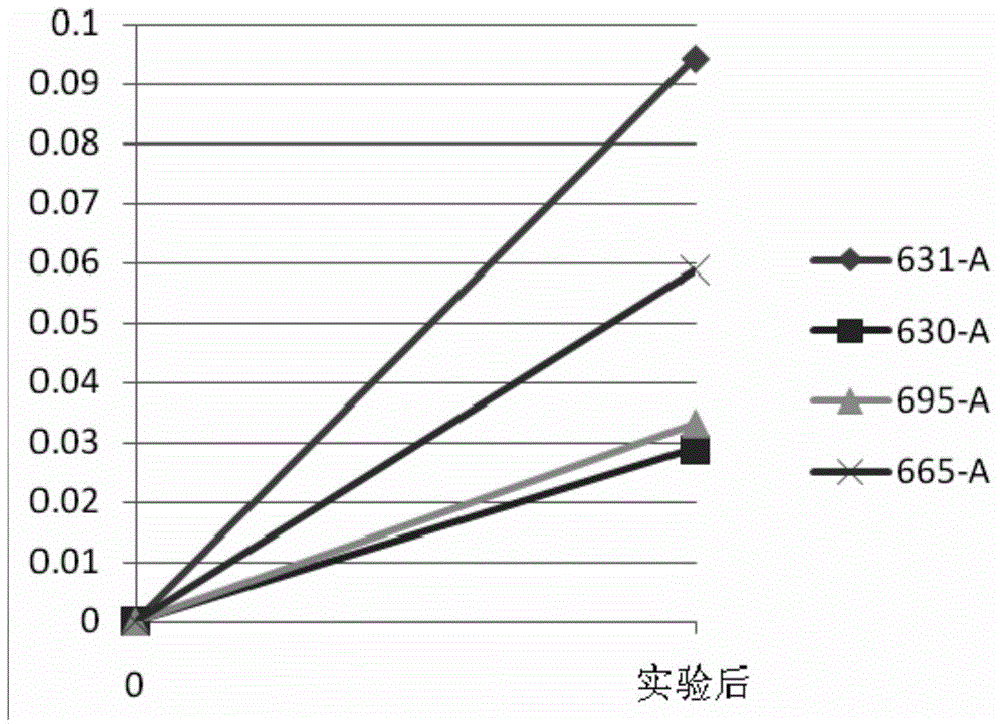

[0120] 1) Using specified instruments, test the initial lightness value and reflectance value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com