IGBT device with carrier storage structure and manufacturing method of IGBT device

A carrier storage and device technology, applied in the field of IGBT devices, can solve the problems of reduced product withstand voltage, reduced channel density, slow depletion speed, etc., to reduce chip cost, chip area, and conduction loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below with reference to the specific drawings and embodiments.

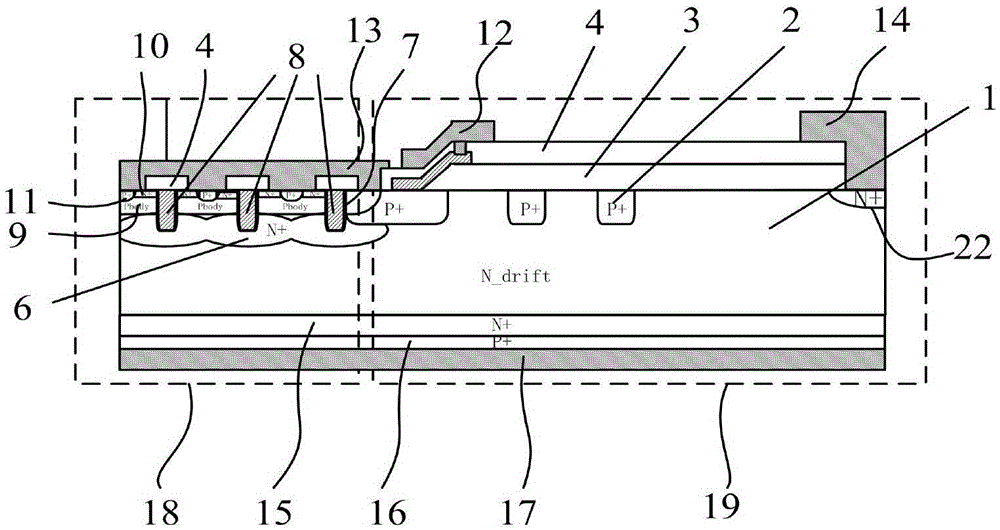

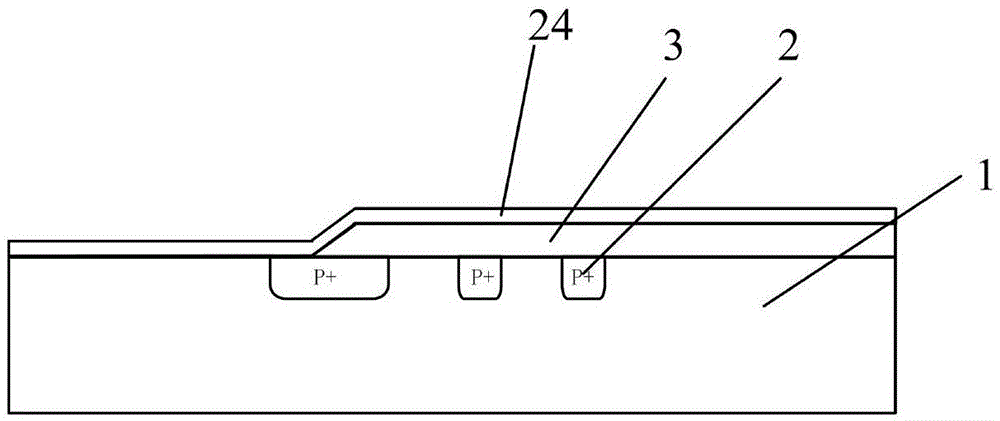

[0050] like figure 1 and Figure 9 Shown: In order to meet the low turn-on voltage drop (Vceon) and extremely fast turn-off characteristics at the same time, and to be able to adjust the guaranteed voltage breakdown position to the cell area to ensure higher resistance to voltage surges Capability, without increasing the cost of chip manufacturing, taking an N-type IGBT device as an example, the present invention specifically includes: on the top view plane of the IGBT device, an active region 18 and a terminal protection zone 19 located on the semiconductor substrate are included. The active area 18 is located in the central area of the semiconductor substrate, and the terminal protection area 19 is located on the outer ring of the active area 18 and surrounds the active area 18; on the cross-section of the IGBT device, the semiconductor substrate has two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com