Na-CO<2> room-temperature secondary battery and manufacture method thereof

A secondary battery, na-co2 technology, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, etc., can solve the problems of Na-CO2 batteries that have not been reported, achieve high energy density, improve utilization rate, improve the transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

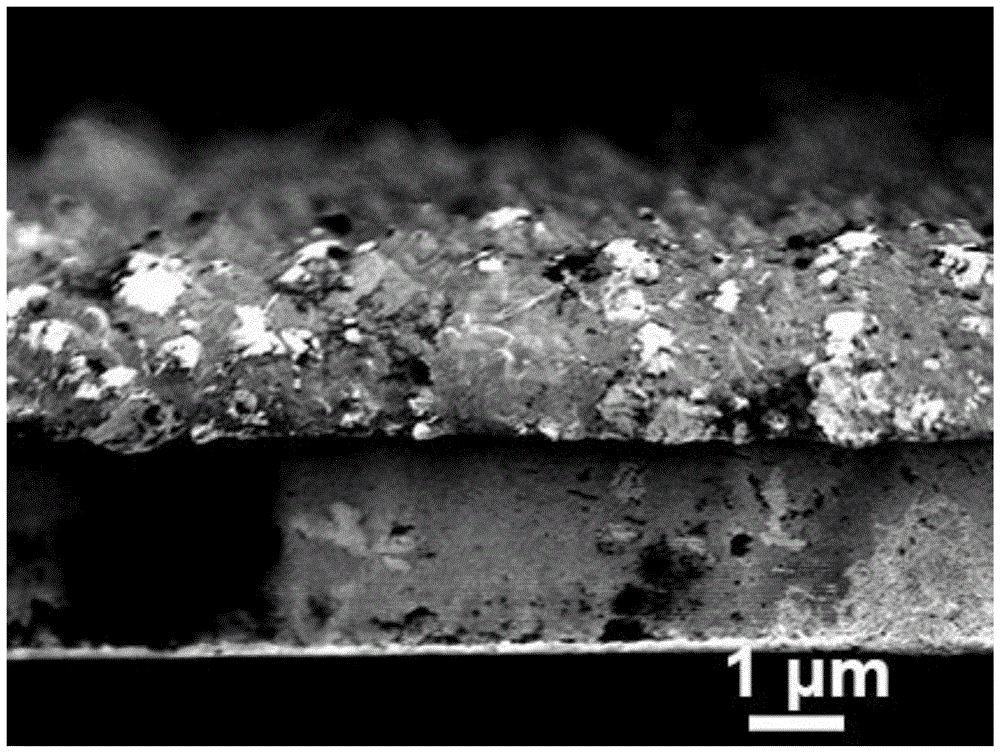

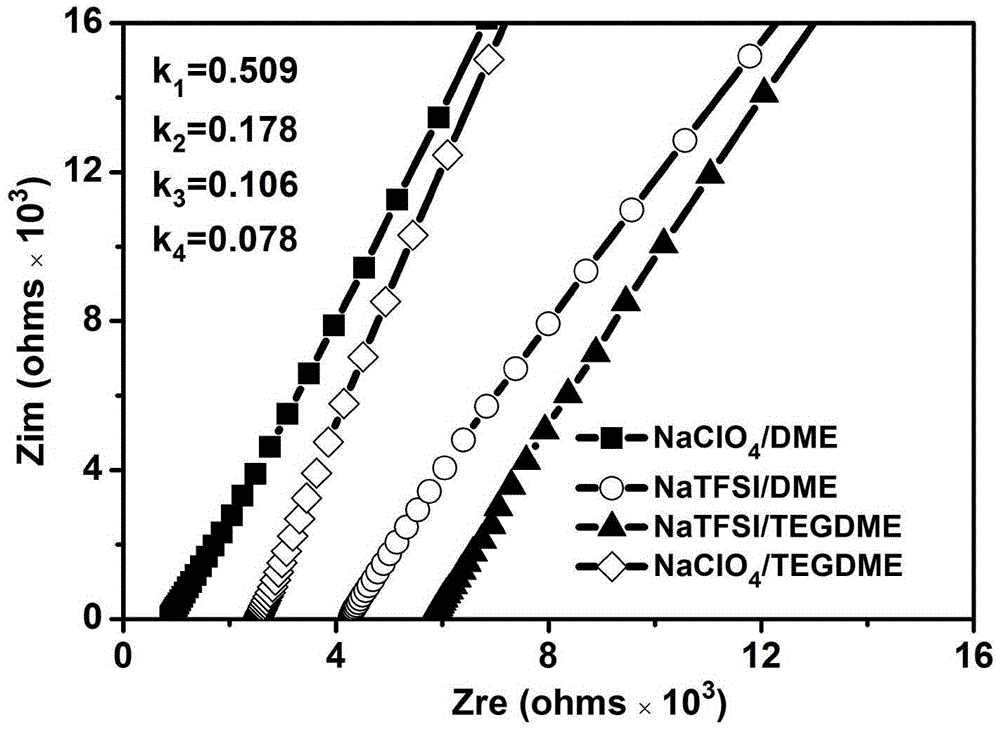

[0046] a Na-CO 2 Room temperature secondary batteries such as Figure 21 As shown, a button battery assembled from negative electrode case 1, shrapnel 2, gasket 3, sodium sheet 4, diaphragm 5, electrolyte, carbon dioxide-air electrode and porous positive electrode case 8, wherein sodium sheet 4 is the negative electrode, carbon dioxide -The air electrode is the positive electrode, and the carbon dioxide-air electrode is composed of a positive electrode catalyst 6 and a current collector 7 with a porous structure; the shrapnel 2 is a stainless steel sheet, which is used to fill the internal space of the battery to improve the airtightness of the battery; the gasket 3 is a stainless steel sheet; the diaphragm 5 is located between the negative electrode sodium sheet 4 and the positive electrode current collector 7, used to block electron transmission; the electrolyte is NaClO 4 / tetraethylene glycol dimethyl ether (TEGDME) solution, the electrolyte is infiltrated in the diaphrag...

Embodiment 2

[0068] One of the Na-CO 2 The preparation method of the room temperature secondary battery, the steps are basically the same as in Example 1, the difference is that the carbon nanotubes are replaced by graphene.

[0069] Figure 12 for Na-CO 2 Battery at 1Ag -1 Under current, intercept 500mAhg -1 charge and discharge curve. It can be seen from the graph that a discharge platform appeared at around 2.2V in the first week, and a charging platform appeared at 3.1V.

Embodiment 3

[0071] One of the Na-CO 2 The preparation method of the room temperature secondary battery is basically the same as in Example 1, except that the carbon nanotubes are replaced by carbon-60 spherical alkenes.

[0072] Figure 13 For button Na-CO 2 Battery at 1Ag -1 Under current, intercept 500mAhg -1 charge and discharge curve. It can be seen from the graph that a discharge platform appeared at around 1.4V in the first week, and a charging platform appeared at 3.5V.

[0073] Na-CO 2 The battery is a brand-new energy storage system based on the quality of the active material Na-CO 2 The battery has 12000Whkg -1 power density. Mass Na-CO based on carbon dioxide and sodium 2 The battery has 1100Whkg -1 theoretical power density. Nearly three times the theoretical energy density of lithium-ion batteries. (Bruce, P.G.; Freunberger, S.A.; Hardwick, L.J.; Tarascon, J.-M., Li–O 2 and Li–Sbatteries with high energy storage. Nature Materials 2011, 11(1), 19-29.)

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com