Electret thin film based energy collector

An energy harvester, electret technology, used in induction generators and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

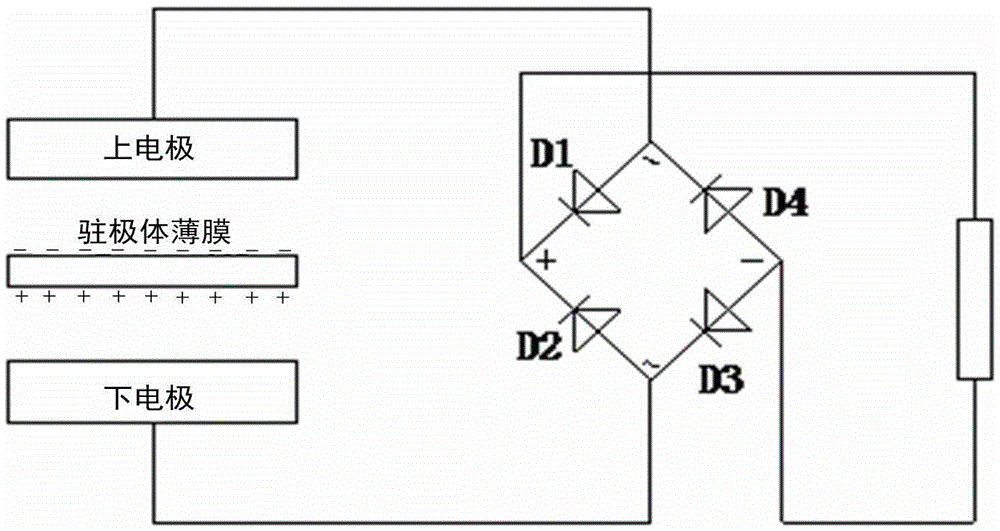

Embodiment 1

[0020] combine figure 1 , The structure of the energy harvester based on the electret film includes an electric energy generating device and a rectifying device. Among them, the electric energy generating device includes an upper electrode, a lower electrode and an electret film, and the electret film adopts a size of 3×3cm 2 , a bipolar electret composite film with a thickness of 2 mm and a maximum amplitude of 1.2 mm, positive and negative charges are distributed on the upper and lower surfaces of the film; the electret film is arranged between the upper electrode and the lower electrode, and does not In contact with any one of the upper and lower electrodes. Connect the diodes D1, D2, D3 and D4 electrically to form a series circuit to form the rectification device of the energy harvester, then electrically connect the connection points of the diodes D1 and D4 to the upper electrode, and connect the connection points of the diodes D2 and D3 to the The lower electrode is el...

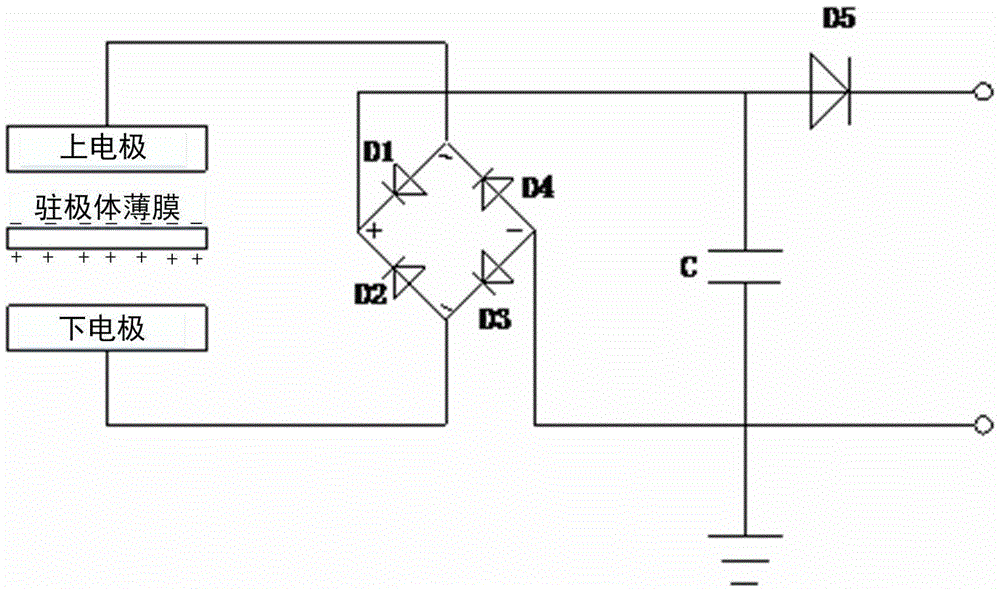

Embodiment 2

[0024] refer to figure 2 , the structure of the electric energy generating device and the rectifying device of this embodiment, and the connection mode of the two are basically the same as that of Embodiment 1, the difference is that: this embodiment also installs an energy storage capacitor in the energy harvester and is used for controlling For the output voltage diode D5, one end of the energy storage capacitor is connected to the connection point of the diodes D1 and D2, and the other end of the energy storage capacitor is grounded; the anode of the diode D5 is connected to the connection point of the diodes D2 and D3, and the cathode is connected to the output terminal.

[0025] The working principle of this embodiment:

[0026] The electret film undergoes thermal polarization and corona polarization, and its internal dipole and space charge are polarized and characterized by the equivalent surface charge, and then the surface of the film has a high voltage after corona ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com