Oil peony seed hulling and cleaning device and process

A cleaning device and oil peony seed technology, applied in the direction of cyclone device, shelling, fat oil/fat production, etc., can solve the problems of low shelling rate, high rate of broken kernels, lack of practical system machinery and equipment, etc., and achieve crushing Low kernel rate, safe and reliable, satisfying the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

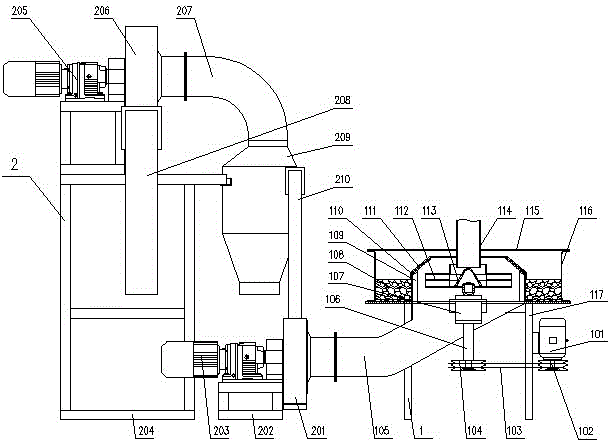

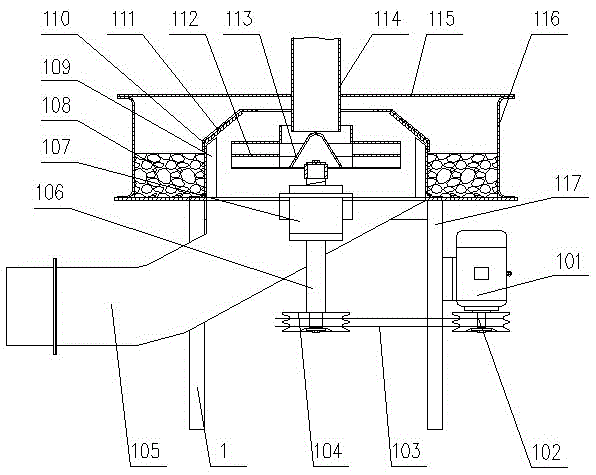

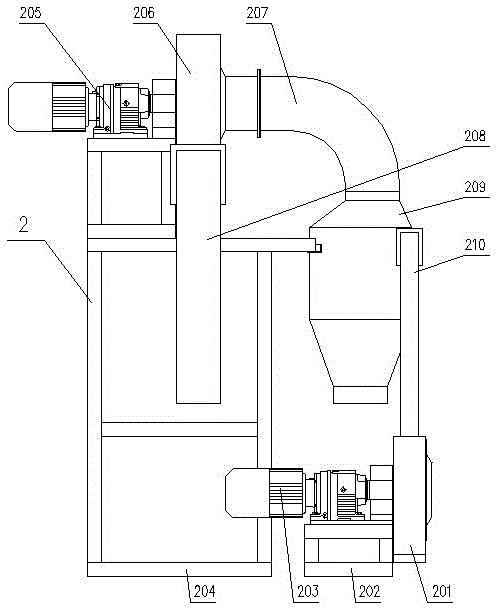

[0022] A shelling and cleaning device for peony seeds, comprising a centrifugal shelling device 1 and a cleaning device 2, the centrifugal shelling device 1 includes a frame 117, a cylinder 116 arranged on the frame 117, a cylinder 116 arranged on the machine The motor 101 on the frame 117, the cover plate 115 arranged on the top of the cylinder, the feed pipe 114 arranged above the cylinder 116 and the discharge port 105 arranged at the bottom of the cylinder 116, the cylinder 116 is provided with a centrifugal spinner 112, located directly below the feed pipe 114, a material guide cone 113 is provided on the centrifugal spinner 112, vertical impact rings 109 are provided on both sides of the centrifugal spinner 112, and an upper impact plate 111 is provided above the vertical impact ring 109, The outer side of the upper impact plate 111 is provided with an upper retaining ring 110, and the vertical impact ring 109, the upper impact plate 111 and the upper retaining ring 110 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com