A diesel engine exhaust particulate matter charge and charge measurement device

A measuring device, diesel engine technology, applied in the direction of electrostatic separation, electrostatic effect separation, external electrostatic separator, etc., can solve the problem of diesel engine exhaust particulate matter charging, etc., to reduce the number of particulate matter, optimize structural parameters, and increase particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

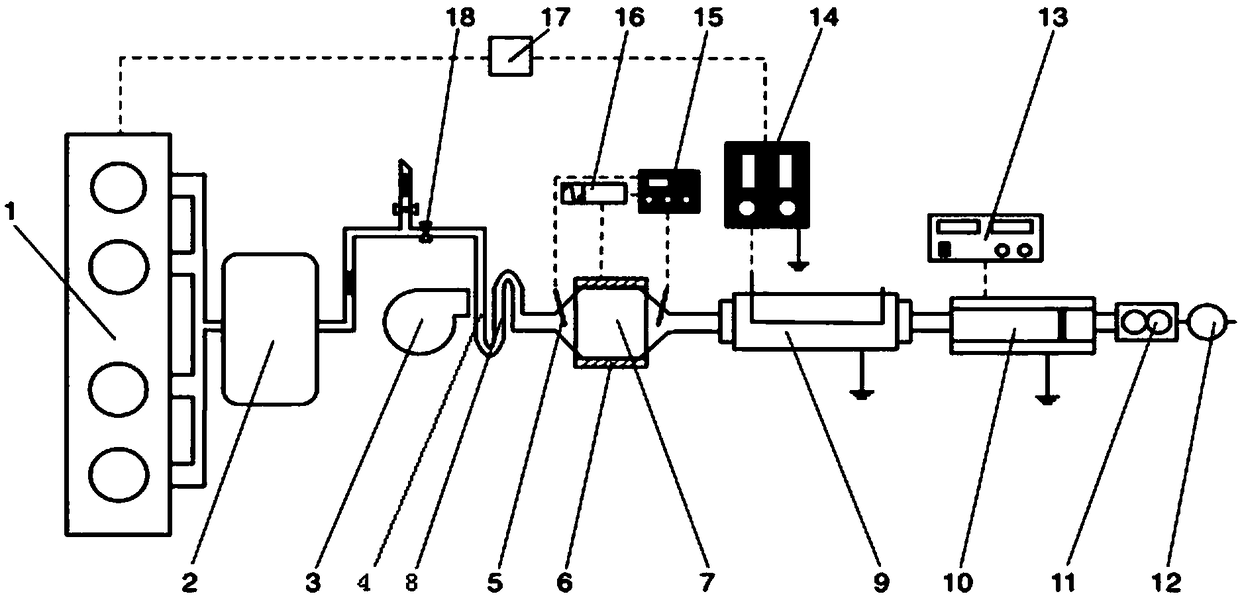

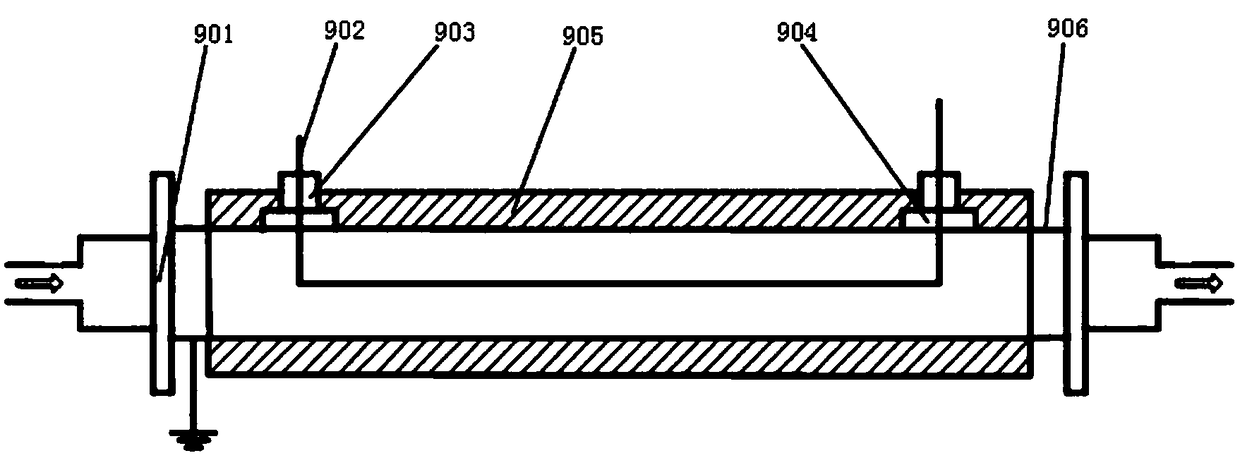

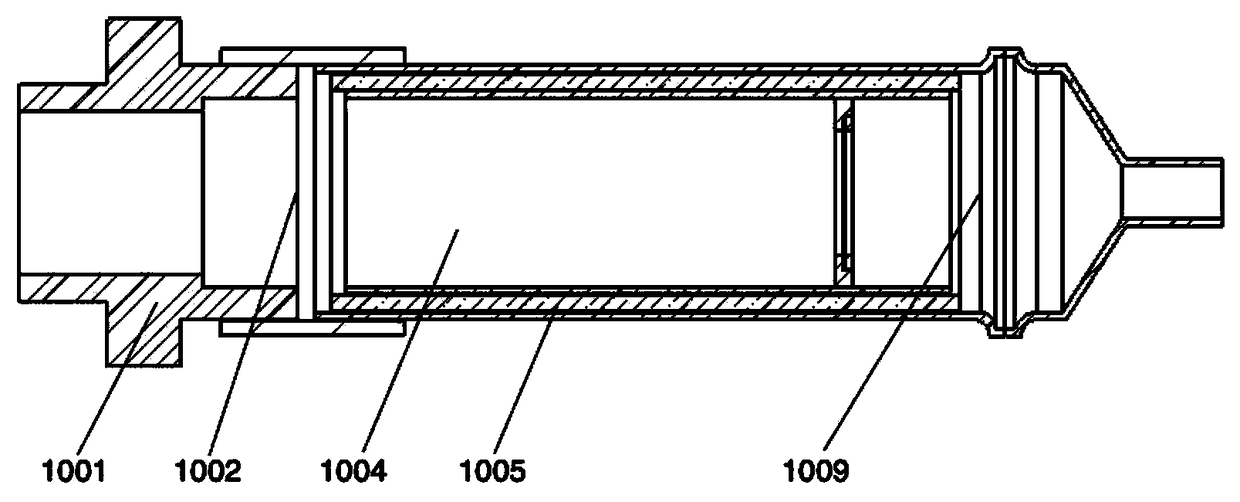

[0032] like figure 1 As shown, it is a schematic diagram of the diesel engine exhaust particulate matter charging and charging quantity measuring device proposed by the present invention. It includes: a voltage stabilizing box 2, a water removal device, a charging reaction device, a charging quantity measuring device and a flow control device; the stabilizing box is connected with the exhaust port of the diesel engine, and is used for easing the exhaust gas flow.

[0033] The water removal device includes a cooling device and a heating device; the cooling device is an air-cooled system, including a stainless steel bellows 4 and a centrifugal fan 3, one end of the stainless steel bellows 4 is connected to the air outlet of the surge tank 2, and the other end is connected to the heating device, a ball valve 18 is provided in the middle of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com