Liquid-phase stripping preparation method of single-layer or few-layer phosphaalkene

A liquid-phase exfoliation and single-layer technology, which is applied in the field of semiconductor material preparation, can solve the problems of low cost, high output, and low efficiency, and achieve the effect of low cost and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment includes the following steps: prepare a solution of flaky black phosphorus and methanol according to a concentration of 0.02 g / mL, and conduct an ultrasonic reaction at a stripping reaction temperature of 40° C. for 6 hours; centrifuge the ultrasonic solution at a speed of 14,000 rpm in a centrifuge After 30 minutes, take the supernatant; drop the solution on a silicon wafer and dry it at 90°C to obtain single-layer or few-layer black phosphorus.

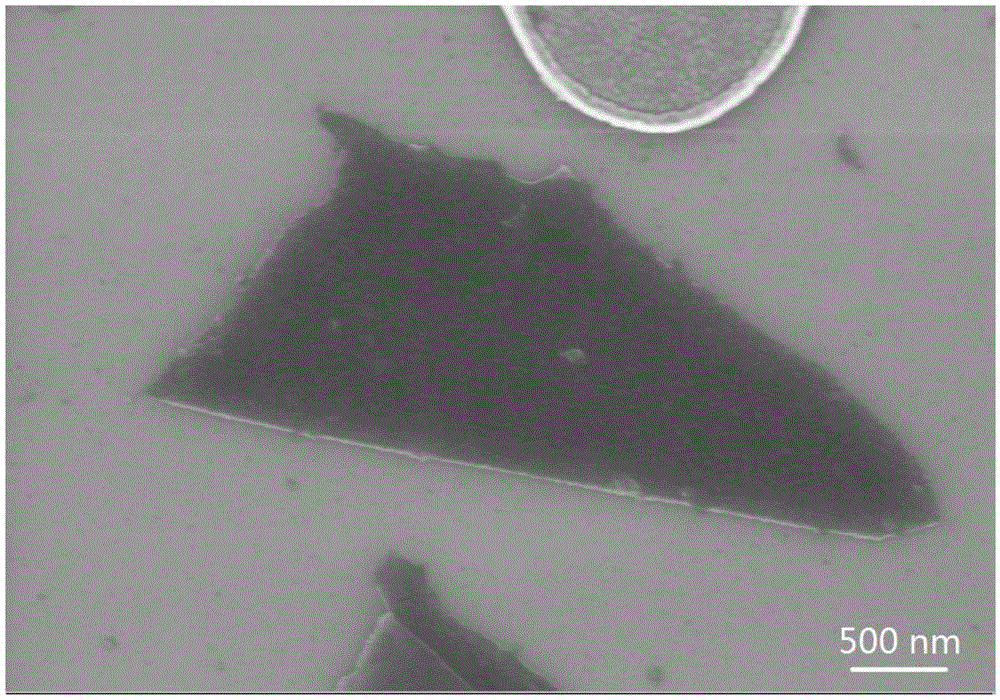

[0025] Such as figure 1 Shown is the SEM photograph of the as-prepared few-layer phosphorene.

[0026] This embodiment includes the following steps: prepare a mixed solution of flaky black phosphorus, methanol, and ethanol according to a concentration of 0.02 g / mL, and perform ultrasonic reaction for 12 hours at a stripping reaction temperature of 40° C.; put the ultrasonic solution under a centrifuge Centrifuge at 14,000 rpm for 30 minutes, and take the supernatant; drop the solution on a silicon wafer and d...

Embodiment 2

[0029] This embodiment includes the following steps: prepare a solution of flaky black phosphorus and methanol at a concentration of 0.1 g / mL, and perform an ultrasonic reaction at a stripping reaction temperature of 40° C. for 24 hours; centrifuge the ultrasonic solution at a speed of 14,000 rpm in a centrifuge After 30 minutes, take the supernatant; drop the solution on the silicon wafer, spin-coat at 500rpm for 60s, and dry at 90°C to obtain a few-layer black phosphorus.

Embodiment 3

[0031] This embodiment includes the following steps: prepare a solution of flaky black phosphorus and isopropanol at a concentration of 0.5 g / mL, and perform an ultrasonic reaction at a stripping reaction temperature of 40° C. for 48 hours; Centrifuge at a rotating speed for 30 minutes, and take the supernatant; drop the solution on a silicon wafer and dry it at 90°C to obtain a few-layer black phosphorus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com