A kind of preparation method of aluminum dihydrogen phosphate crystal powder

A technology of aluminum dihydrogen phosphate and crystals, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc. Drying and other issues, to achieve high economic and social value, suitable for long-distance transportation, high output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

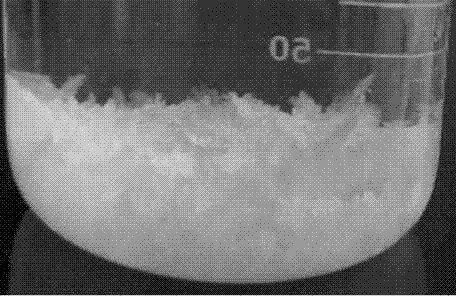

Image

Examples

Embodiment 1

[0013] The phosphoric acid solution with a concentration of 80 wt%, ammonia water and distilled water with a concentration of 30 wt% are formulated into a solution in a volume ratio of 10:3:5; then aluminum nitrate and urea are added to the solution, wherein aluminum nitrate, urea The addition amount is respectively 1 / 3 and 1 times of the molar number of phosphoric acid; Add iodine (I 2 ) powder, cetyl ethyl morpholine ethyl ammonium sulfate, and control the addition of iodine powder, cetyl ethyl morpholine ethyl ammonium sulfate to be 0.015%, 0.1% of the solution quality respectively; the solution is heated to 98°C, and continuously stirred with a stirrer for 5 hours; after the stirring, the solution was naturally cooled to room temperature, then stood still and aged for 3 hours, then filtered and separated, and the filtered product was washed with absolute ethanol for 3 times, and then in 60 °C for 4 hours. Find by XRD, infrared analysis: the crystalline phase of the powder...

Embodiment 2

[0015] Phosphoric acid solution with a concentration of 80 wt%, ammonia water and distilled water with a concentration of 30 wt% are formulated into a solution in a ratio of 10:3:5 by volume; then aluminum nitrate and urea are added to the solution, wherein aluminum nitrate, urea The addition amount is respectively 1 / 3 and 3 times of the molar number of phosphoric acid; Add iodine (I 2 ) powder, cetyl ethyl morpholine ethyl ammonium sulfate, and control the addition of iodine powder, cetyl ethyl morpholine ethyl ammonium sulfate to be 0.015%, 0.1% of the solution quality respectively; the solution is heated to 92°C, and continuously stirred with a stirrer for 7 hours; after the stirring, the solution was naturally cooled to room temperature, then stood still and aged for 3 hours, then filtered and separated, and the filtered product was washed with absolute ethanol for 3 times, and then at 70 °C for 4 hours. Find by XRD, infrared analysis: the crystalline phase of the powder ...

Embodiment 3

[0017] The phosphoric acid solution with a concentration of 80 wt%, ammonia water and distilled water with a concentration of 30 wt% are formulated into a solution in a volume ratio of 10:3:5; then aluminum nitrate and urea are added to the solution, wherein aluminum nitrate, urea The addition amount is respectively 1 / 3 and 4 times of the molar number of phosphoric acid; Add iodine (I 2 ) powder, cetyl ethyl morpholine ethyl ammonium sulfate, and control the addition of iodine powder, cetyl ethyl morpholine ethyl ammonium sulfate to be 0.015%, 0.1% of the solution quality respectively; the solution is heated to 85°C, and continuously stirred with a stirrer for 8 hours; after the stirring, the solution was naturally cooled to room temperature, then stood still and aged for 3 hours, then filtered and separated, and the filtered product was washed with absolute ethanol for 3 times, and then in 80 °C for 2 hours. Find by XRD, infrared analysis: the powder prepared by the technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com