Method for harmlessly treating high-zinc and high-lead sludge

A harmless treatment of sludge, applied in the harmless treatment of lead sludge, high zinc field, can solve the problems of water and soil heavy metal pollution, achieve good environmental and social benefits, reduce production costs, prices cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

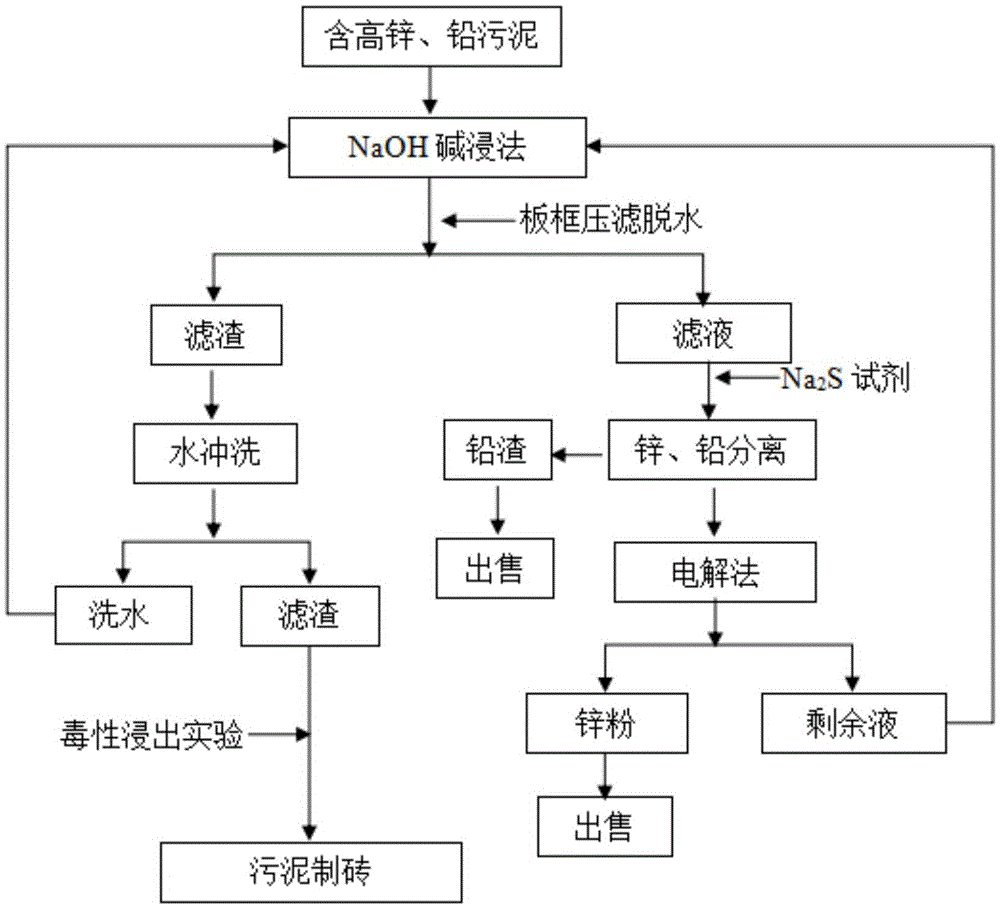

[0047] combine figure 1 , a method for harmless treatment of sludge containing high zinc and lead, the steps of which are:

[0048] A. Using steel wire rope factory pickling sludge with a lead content of 0.4-2% and a zinc content of 3-15% as raw material, dry the steel wire rope sludge containing high zinc and lead to constant weight; drying of steel wire rope sludge The temperature is 100-105°C, which does not change the material composition of the sludge.

[0049] The raw material used in the present invention is steel wire rope pickling sludge that cannot be effectively treated for a long time and is harmful to the environment, which belongs to hazardous solid waste. The mud output is large and stable, the price is low and needs to be disposed of urgently, there is no shortage of raw materials, the production cost is reduced, and good environmental and social benefits are obtained.

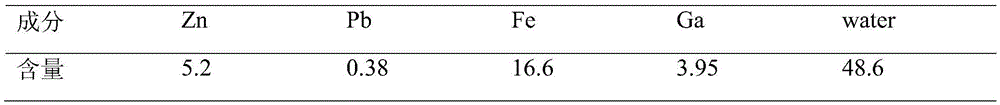

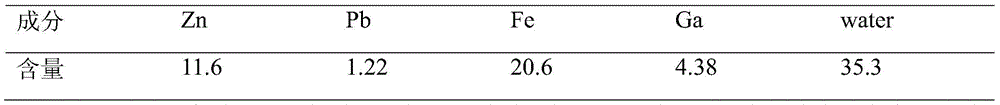

[0050] The composition of the raw materials required by the present invention is relative...

Embodiment 2

[0063] This embodiment is the same as embodiment 1, wherein, in step A, use the steel wire rope factory pickling sludge with a lead content of 0.4% and a zinc content of 3% as raw material, and dry the steel wire rope sludge containing high zinc and lead until constant Heavy; the drying temperature of the wire rope sludge is 100°C, which does not change the composition of the sludge;

[0064] In step C, the crushed wire rope sludge is added to 160g / L NaOH solution for reaction, and the dosage ratio is that 1 ton of dry sludge needs 5 cubic meters of strong alkali solution; Stirring at low speed, the reaction time is 60min, under the optimal reaction temperature, fully react to achieve the best extraction efficiency;

[0065] In step D, filter, rinse with water, and rinse 3 times;

[0066] In step E, add the sulfide separating agent reaction in the filtered gained zinc, lead complex filtrate; 2 S reagent was used as a separating agent, adding Na 2The S separating agent is 4 ...

Embodiment 3

[0071] This embodiment is the same as embodiment 1, wherein, in step A, the steel wire rope factory pickling sludge with a lead content of 2% and a zinc content of 15% is used as raw material, and the steel wire rope sludge containing high zinc and lead is dried to constant temperature. Heavy; the drying temperature of the wire rope sludge is 105°C, which does not change the composition of the sludge;

[0072] In step C, the crushed wire rope sludge is added to 240g / L NaOH solution for reaction, and the dosage ratio is 20 cubic meters of strong alkali solution for 1 ton of dry sludge; the reaction temperature is 70°C, and the reaction temperature is 600 rpm Stirring at low speed, the reaction time is 80min, under the optimum reaction temperature, fully react to achieve the best extraction efficiency;

[0073] In step D, filter, dehydrate and filter by plate and frame filter press, rinse the filter residue with water, and rinse 5 times;

[0074] In step E, add the sulfide sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com