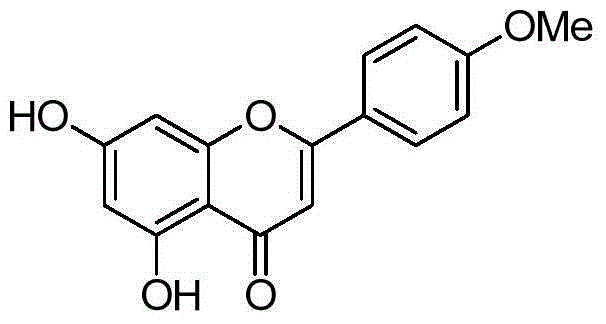

A preparing method of acacetin

The technology of acacetin and compound is applied in the field of preparation of acacetin, which can solve the problems of cumbersome operation, high cost and low yield, and achieve the effect of simple operation, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

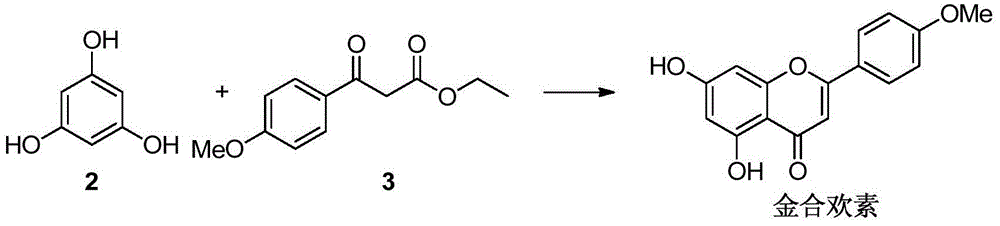

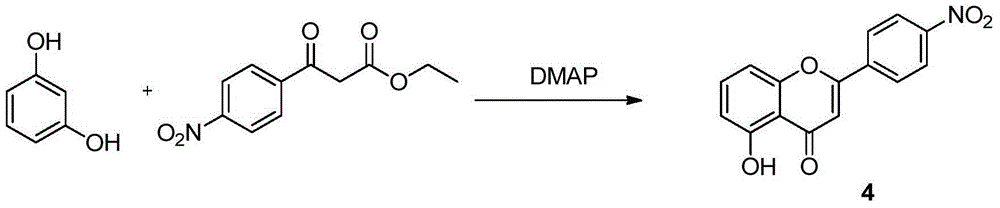

Method used

Image

Examples

Embodiment 1

[0024] Under the conditions of anhydrous, oxygen-free, and nitrogen protection, compound 2 (1.1g) and compound 3 (3.1g) were placed in a 50ml reaction flask, 4-dimethylaminopyridine (53mg) was added, and at a temperature of 200°C The reaction was carried out for 1.5 hours. After cooling, a solid precipitated out. Suction filtration and column chromatography gave 2.2 g of acacetin, with a yield of 89%, HPLC purity of 99.35%, and mp: 266°C.

Embodiment 2

[0026] Under the conditions of anhydrous, oxygen-free, and nitrogen protection, compound 2 (1.1g) and compound 3 (3.9g) were placed in a 50ml reaction flask, 4-pyrrolidinylpyridine (130mg) was added, and at a temperature of 180°C, The reaction was carried out for 3 hours. After cooling, a solid precipitated out. Suction filtration and column chromatography gave 2.1 g of acacetin, with a yield of 86%, HPLC purity of 97.8%, and mp: 264°C.

Embodiment 3

[0028] Under the conditions of anhydrous, oxygen-free, and nitrogen protection, compound 2 (1.1g) and compound 3 (1.9g) were placed in a 50ml reaction flask, tri-n-butylphosphine (133mg) was added, and at a temperature of 190°C, The reaction was refluxed for 2 hours. After cooling, a solid precipitated out. Suction filtration and column chromatography gave 1.86 g of acacetin with a yield of 75%. HPLC purity was 99.5%, and mp: 267°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com