A kind of preparation technology of cefotazone

A preparation process, the technology of ceftizonam, which is applied in the field of medicine, can solve the problems of no mature preparation process, etc., and achieve the effect of reducing process cost, cheap price and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

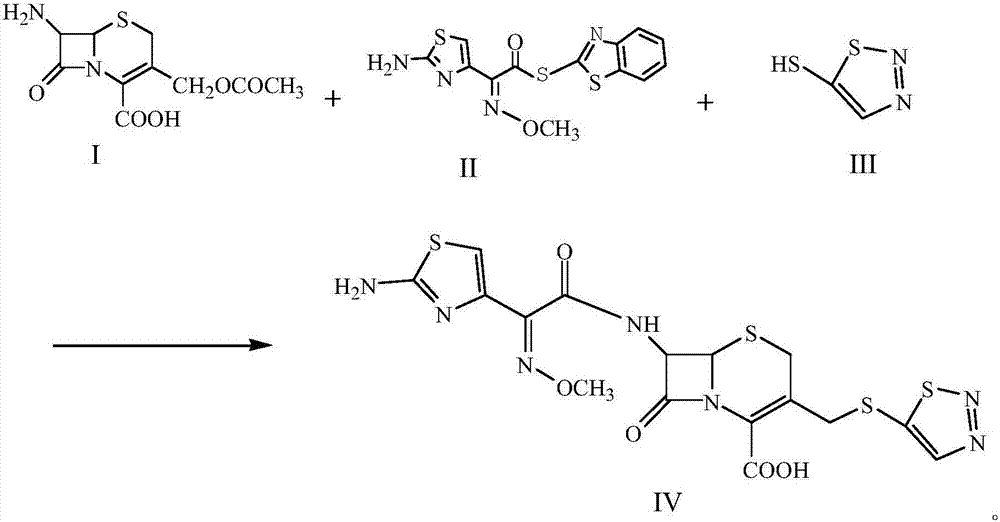

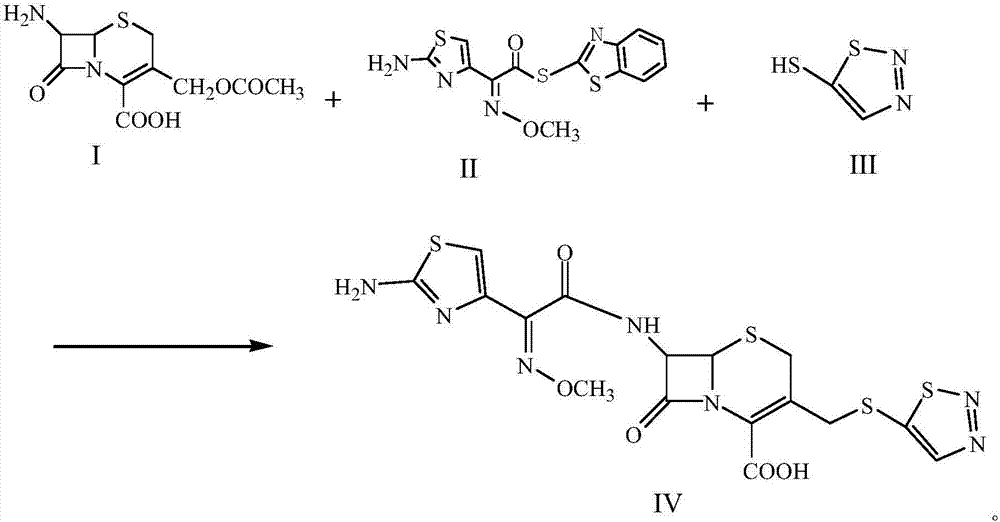

Method used

Image

Examples

Embodiment 1

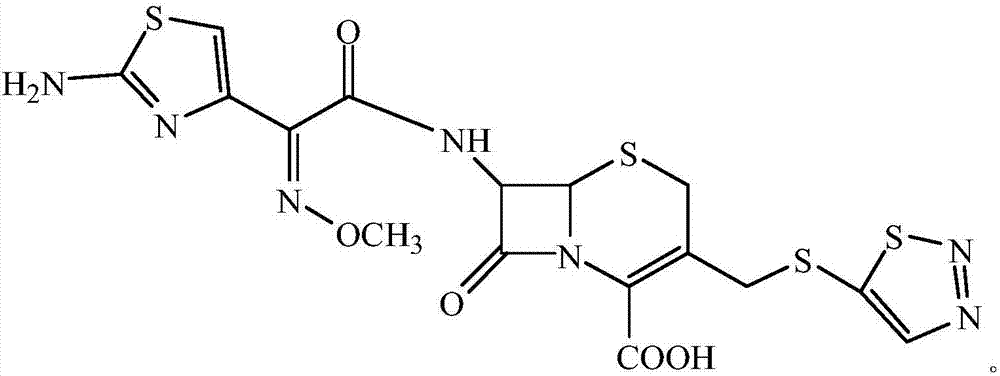

[0026] A kind of preparation technology of ceftizonam of the present invention comprises steps:

[0027] (1) Weigh 2.72g 7-aminocephalosporanic acid (7-ACA, compound I, MW272, 0.01mol), 3.5g AE-active ester (MAEM, compound VII, MW350, 0.01mol), mix and grind evenly, then Add 1.18g of compound III (MW118, 0.01mol) and 21.76g of triethylamine, stir to make the solid-liquid phase fully contact, add 27.2g of polyethylene glycol 400, and stir for 2 minutes;

[0028] (2) 450W microwave reaction for 2 minutes, 800W microwave reaction for 2 minutes, 1000W microwave reaction for 3 minutes;

[0029] (3) After the reaction, the reaction residue was washed with cold water at 0°C, and the remaining solid was dissolved in 48.96g of ethyl acetate, and 13.6g of petroleum ether at 0°C was added to precipitate a white solid, which was vacuum-dried at 40°C for 4 hours to obtain 5.02 gCompound IV (MW513), the yield is 97.9%, the purity is over 99.9%, the single impurity is less than 0.01%, and t...

Embodiment 2

[0032] A kind of preparation technology of ceftizonam of the present invention comprises steps:

[0033] (1) Weigh 2.72g 7-aminocephalosporanic acid (7-ACA, compound I, MW272, 0.01mol), 4.2g AE-active ester (MAEM, compound VII, MW350, 0.012mol), mix and grind evenly, then Add 1.416g of compound III (MW118, 0.012mol) and 27.2g of triethylamine, stir to make the solid-liquid phase fully contact, add 32.64g of polyethylene glycol 400, and stir for 5 minutes;

[0034] (2) 450W microwave reaction for 3 minutes, 800W microwave reaction for 3 minutes, 1000W microwave reaction for 5 minutes;

[0035] (3) After the reaction, the reaction residue was washed with cold water at 5°C, and the remaining solid was dissolved in 65.28g of ethyl acetate, and 21.76g of petroleum ether at 5°C was added to precipitate a white solid, which was vacuum-dried at 50°C for 6 hours to obtain 5.04 gCompound IV (MW513), the yield is 98.2%, the purity is over 99.9%, the single impurity is less than 0.01%, a...

Embodiment 3

[0038] A kind of preparation technology of ceftizonam of the present invention comprises steps:

[0039] (1) Weigh 2.72g 7-aminocephalosporanic acid (7-ACA, compound I, MW272, 0.01mol), 3.85g AE-active ester (MAEM, compound VII, MW350, 0.011mol), mix and grind evenly, then Add 1.298g of compound III (MW118, 0.011mol) and 24.48g of triethylamine, stir to fully contact the solid-liquid phase, add 29.92g of polyethylene glycol 400, and stir for 3 minutes;

[0040] (2) 450W microwave reaction for 2 minutes, 800W microwave reaction for 3 minutes, 1000W microwave reaction for 4 minutes;

[0041] (3) After the reaction, the reaction residue was washed with cold water at 0°C, and the remaining solid was dissolved in 54.4g of ethyl acetate, and 19.04g of petroleum ether at 0°C was added to precipitate a white solid, which was vacuum-dried at 40°C for 6 hours to obtain 5.09 gCompound IV (MW513), the yield is 99.2%, the purity is over 99.9%, the single impurity is less than 0.01%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com