Strong inhibition and strong blocking drilling fluid and preparation method thereof

A drilling fluid and inhibition technology, applied in the field of drilling fluid and its preparation, can solve problems such as good anti-slump performance, and achieve the effects of preventing wellbore collapse, good wellbore collapse, and inhibiting hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

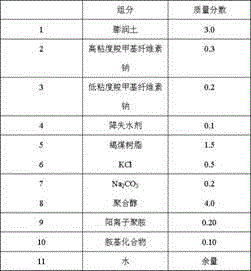

Embodiment 1

[0016] Cationic polyamine is the reaction product of butylenediamine, butylene oxide and epoxychlorobutane. The preparation method is to add butylene oxide dropwise to butylenediamine under the condition of stirring and 100℃, react for 1h, and then The temperature was raised to 140°C, and epichlorobutane was added dropwise under stirring, formic acid was added for 1 hour of reaction, and the reaction was continued for 1 hour to obtain a polyamine inhibitor sample. Control the molar ratio of butanediamine, butylene oxide, epoxychlorobutane and formic acid to 1:4:0.4:0.8, and its kinematic viscosity is 456.4mm 2 / s, cationic degree is 0.906mmol / g. The preparation method of the amino compound is to add 103g of diethylenetriamine and 0.5g of potassium hydroxide under stirring, mix well, heat up to 80°C, and gradually add 232g of propylene oxide dropwise (the molar ratio of propylene oxide to diethylenetriamine is 4 : 1), after the dropwise addition, react at 80°C for 8h, cool dow...

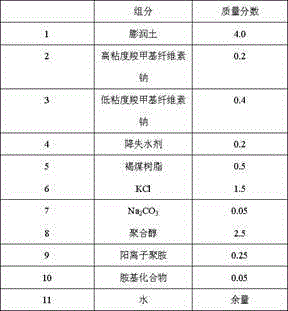

Embodiment 2

[0020] Cationic polyamine is the reaction product of butylenediamine, butylene oxide and epoxychlorobutane. The preparation method is to add butylene oxide dropwise to butylenediamine under the condition of stirring and 100℃, react for 1h, and then The temperature was raised to 140°C, and epichlorobutane was added dropwise with stirring, formic acid was added for 1 hour of reaction, and the reaction was continued for 1 hour to obtain a polyamine inhibitor sample. Control the molar ratio of butanediamine, butylene oxide, epoxychlorobutane and formic acid to 1:4:0.4:0.8, and its kinematic viscosity is 456.4mm 2 / s, cationic degree is 0.906mmol / g. The preparation method of the amino compound is to add 146g of triethylenetetramine and 0.73g of potassium hydroxide under stirring, mix well, raise the temperature to 90°C, and gradually add 116g of propylene oxide dropwise (the molar ratio of propylene oxide to diethylenetriamine is 3 : 1), after the dropwise addition, react at 90°C ...

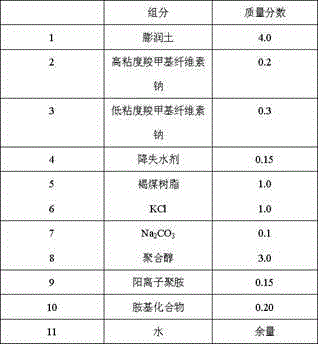

Embodiment 3

[0024] Cationic polyamine is the reaction product of butylenediamine, butylene oxide and epoxychlorobutane. The preparation method is to add butylene oxide dropwise to butylenediamine under the condition of stirring and 100℃, react for 1h, and then The temperature was raised to 140°C, and epichlorobutane was added dropwise with stirring, formic acid was added for 1 hour of reaction, and the reaction was continued for 1 hour to obtain a polyamine inhibitor sample. Control the molar ratio of butanediamine, butylene oxide, epoxychlorobutane and formic acid to 1:4:0.4:0.8, and its kinematic viscosity is 456.4mm 2 / s, cationic degree is 0.906mmol / g. The preparation method of the amino compound is to add 146g of triethylenetetramine and 0.94g of potassium hydroxide under stirring, mix well, raise the temperature to 100°C, and gradually add 116g of propylene oxide (the molar ratio of propylene oxide to diethylenetriamine is 2 : 1), after the dropwise addition, react at 100°C for 9h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com