Solid fuel fluidized bed pyrolysis, gasification and combustion graded conversion device and conversion method

A solid fuel, pyrolysis gasification technology, applied in the direction of gasification process, combustible gas production, petroleum industry, etc., can solve the problems of semi-coke graded utilization, semi-coke conversion difficulty, poor adaptability of solid fuel, etc., to achieve oxidant consumption Small amount, excellent heat utilization effect, and high active ingredient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

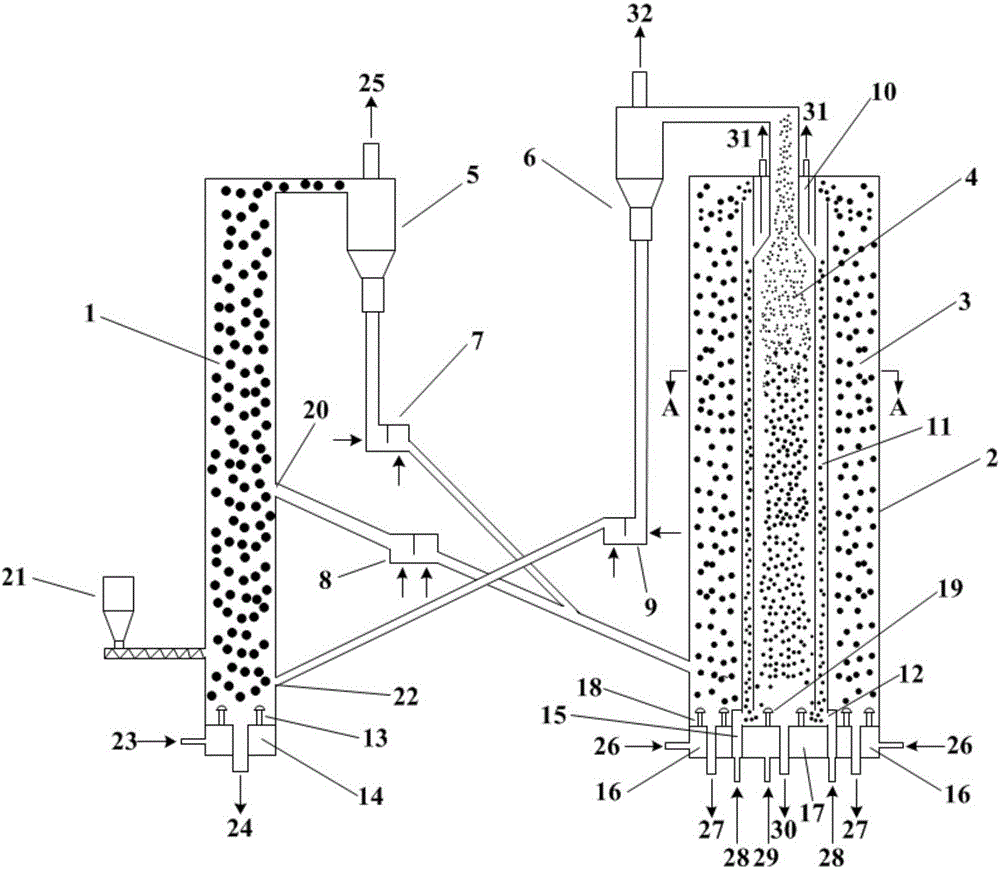

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

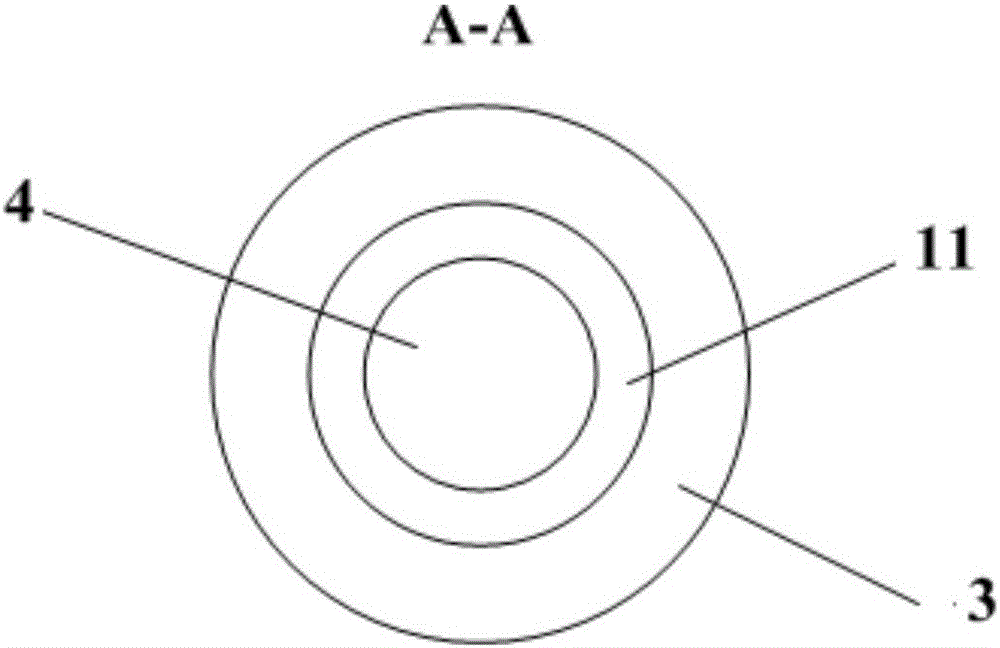

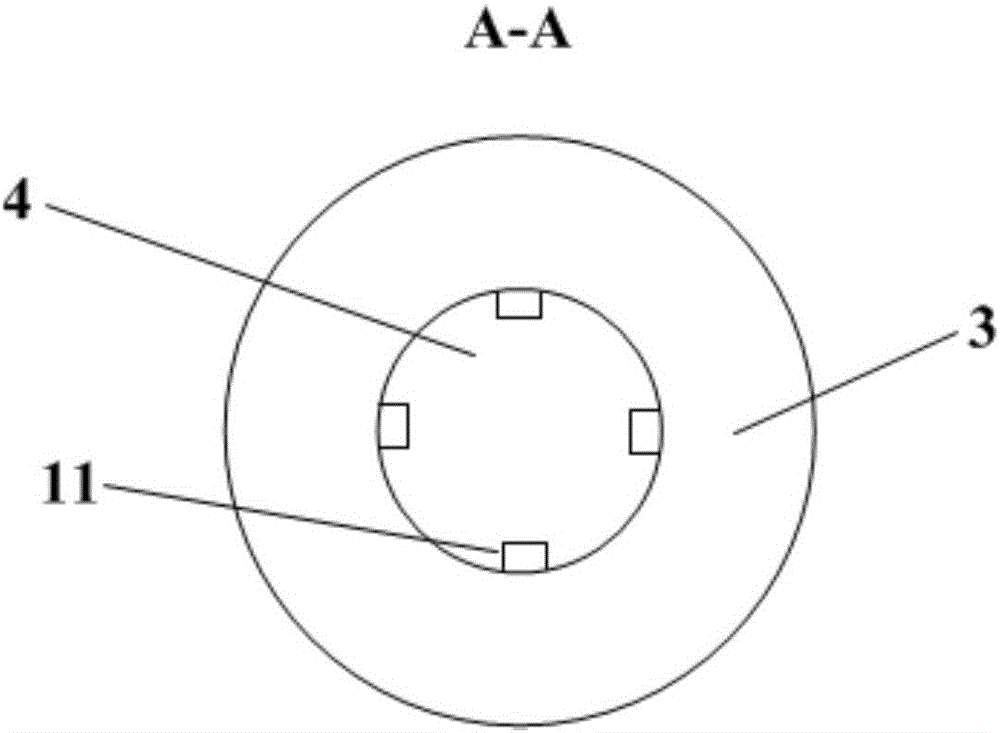

[0022] The invention is a solid fuel fluidized bed pyrolysis gasification combustion graded conversion device. as attached figure 1 As shown, including: fluidized bed pyrolysis furnace 1, pyrolysis furnace cyclone separator 5, fly ash return device 7, semi-coke return device 8, multi-layer fluidized bed cyclone separator 6, hot ash return device 9. Among them, the upper part of the fluidized bed pyrolysis furnace 1 is a dilute phase area, and the lower part is a dense phase area, and the top of the dense phase area is provided with a semi-coke overflow port 20, and the semi-coke overflow port 20 is connected with the semi-coke return material The feeding chamber of the device 8 is connected; the bottom of the fluidized bed pyrolysis furnace 1 is arranged with a pyrolysis furnace air chamber 14, and the pyrolysis furnace air chamber 14 is connected to the circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com