Technique for preparing squid skin collagen peptide through enzymic method

A technology of enzymatic preparation and process method, applied in the direction of fermentation, etc., can solve the problems of low utilization rate of raw materials of aquatic products, environmental pollution, waste of resources, etc., and achieve the effect of ideal conversion rate of polypeptide, high theoretical guidance significance, and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

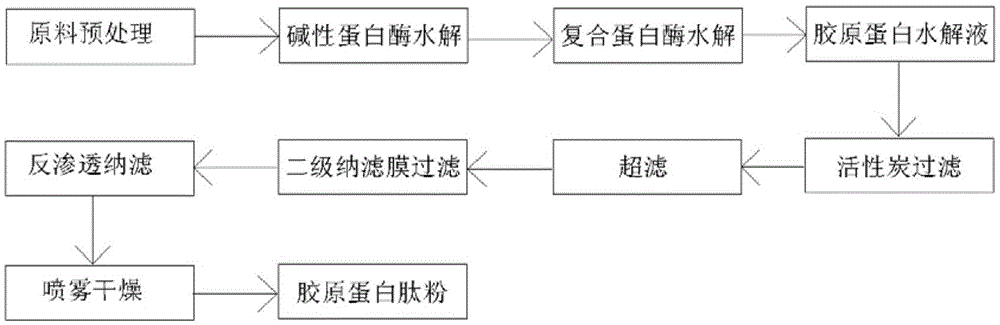

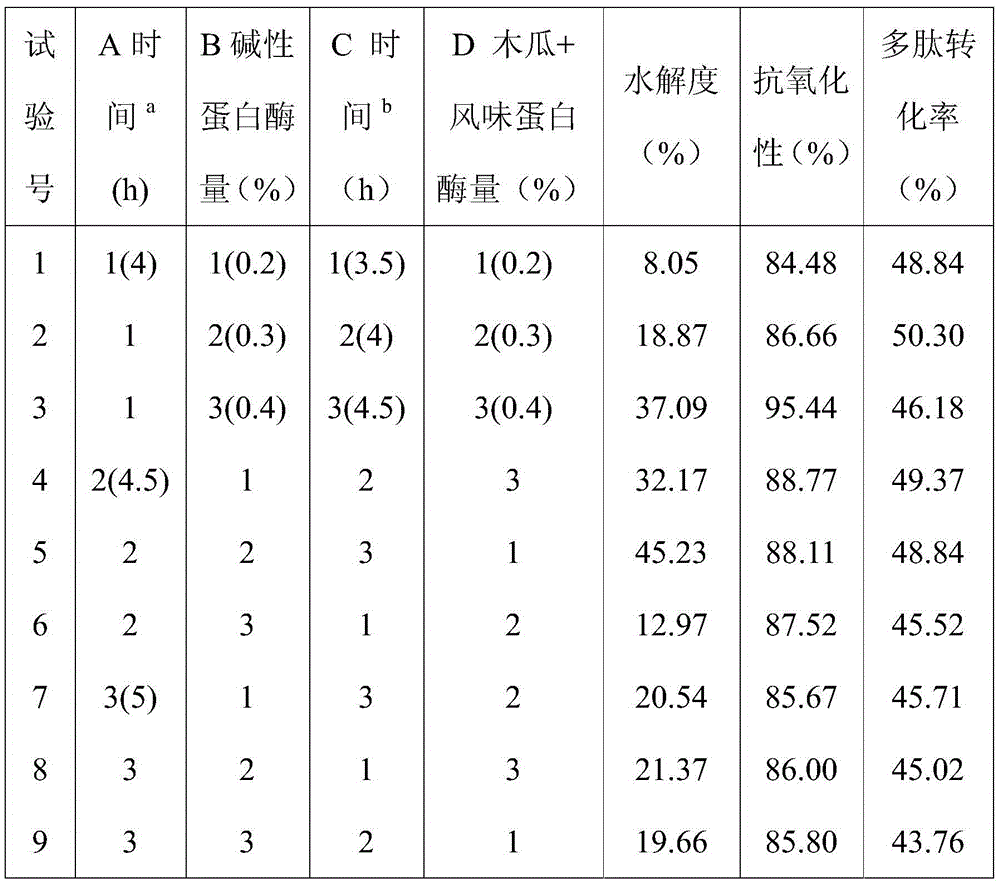

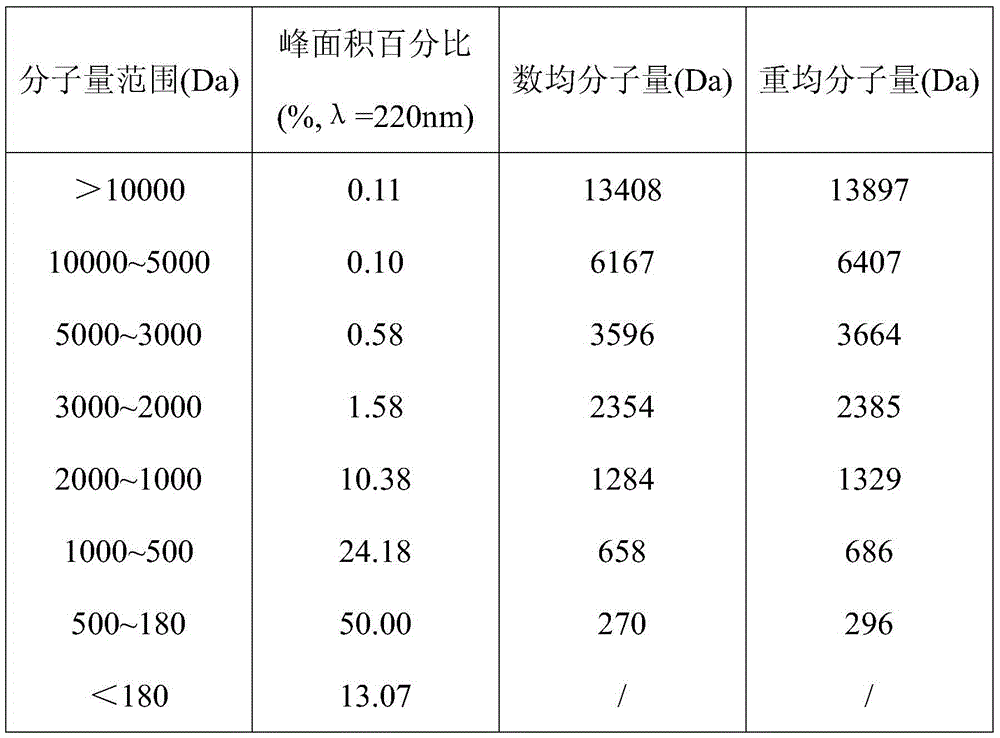

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0016] Materials and Reagents

[0017] Squid skin: purchased from Zhoushan squid processing factory, washed and drained, and stored in a -20°C refrigerator.

[0018] Alkaline protease (2.4AU / g), flavor protease (500LAPU / g): Novozymes; papain (200000U / g): Guangxi Nanning Pangbo Bioengineering Co., Ltd.; Gly-Gly-Tyr-Arg: Sigma ; Diphenylpicryl radical (DPPH), copper sulfate, concentrated sulfuric acid, potassium sulfate, ninhydrin, fructose, glycine, trichloroacetic acid, absolute ethanol, sodium hydroxide, concentrated hydrochloric acid, etc. are analytically pure.

[0019] Instruments and Equipment

[0020] HH2 digital display constant temperature water bath: Guohua Electric Co., Ltd.; RE-52 rotary evaporator: Shanghai Jiapeng Technology Co., Ltd.; UV-2550 ultraviolet-visible spectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com