High-strength alloy cast aluminum spiral-flow constant-pressure pump material and preparing method and application of high-strength alloy cast aluminum spiral-flow constant-pressure pump material

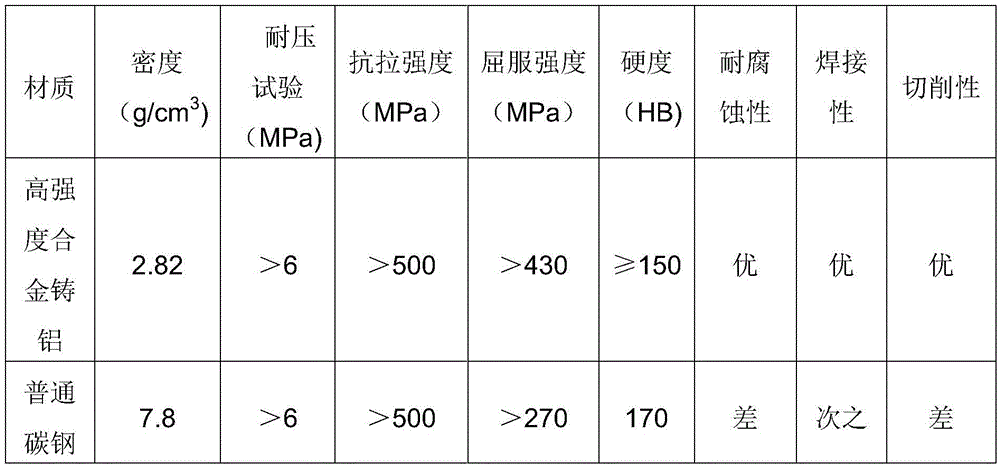

A technology of helical flow constant pressure pump and high-strength alloy, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as the inability to meet the requirements of light-weight and corrosion-resistant fire-fighting pumps. , to achieve the effect of weight reduction, good corrosion resistance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The high-strength alloy cast aluminum spiral flow constant pressure pump material is smelted in a 500Kg intermediate frequency induction furnace. The process steps are: (1) tools, ladles, refining agents used in the smelting process, and pre-baked for at least 4 hours. (2) Preheat the medium frequency induction furnace with 60Kw power, and remove impurities on the crucible wall at the same time. (3) Put the high-quality aluminum alloy ingot into the furnace, turn on the electricity and melt it, measure the temperature of the molten aluminum with a thermometer, when the temperature rises to 720-730 degrees Celsius, add the refining agent, install the argon refiner, and start the power supply of the refiner, Refining time is 4 minutes to remove surface slag. (4) Start the power supply of the refining machine, turn on the switch of the argon gas cylinder, adjust the pressure to 0.12 MPa, insert the vent tube into the alloy liquid and start refining and degassing, and the t...

Embodiment 2

[0027] The high-strength alloy cast aluminum spiral flow constant pressure pump material is smelted in a 1000Kg intermediate frequency induction furnace. The process steps are: (1) tools, ladles, refining agents used in the smelting process, and pre-baked for at least 5 hours. (2) Preheat the medium frequency induction furnace with 50Kw power, and remove the impurities on the crucible wall at the same time. (3) Put the high-quality aluminum alloy ingot into the furnace, turn on the electricity and melt it, measure the temperature of the molten aluminum with a thermometer, when the temperature rises to 730-740 degrees Celsius, add the refining agent, install the argon refiner, and start the power supply of the refiner, Refining time is 5 minutes to remove surface slag. (4) Start the power supply of the refining machine, turn on the switch of the argon gas bottle, adjust the pressure to 0.15MPa, insert the vent tube into the alloy liquid and start refining and degassing for 30 m...

Embodiment 3

[0034]The high-strength alloy cast aluminum spiral flow constant pressure pump material is smelted in a 1000Kg intermediate frequency induction furnace. The process steps are: (1) tools, ladles, refining agents used in the smelting process, and pre-baked for at least 5 hours. (2) Preheat the medium frequency induction furnace with 70Kw power, and remove the impurities on the crucible wall at the same time. (3) Put the high-quality aluminum alloy ingot into the furnace, turn on the electricity and melt it, measure the temperature of the molten aluminum with a thermometer, when the temperature rises to 710-720 degrees Celsius, add the refining agent, install the argon refiner, and start the power supply of the refiner, Refining time is 3 minutes to remove surface slag. (4) Start the power supply of the refiner, turn on the switch of the argon gas cylinder, adjust the pressure to 0.10MPa, insert the vent tube into the alloy liquid and start refining and degassing for 25 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com