Cyanide-free silver electroplating liquid

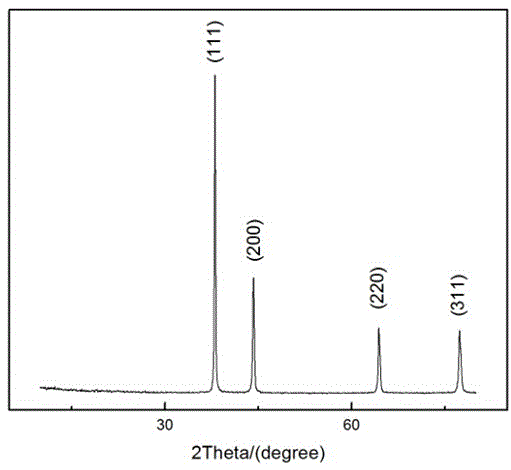

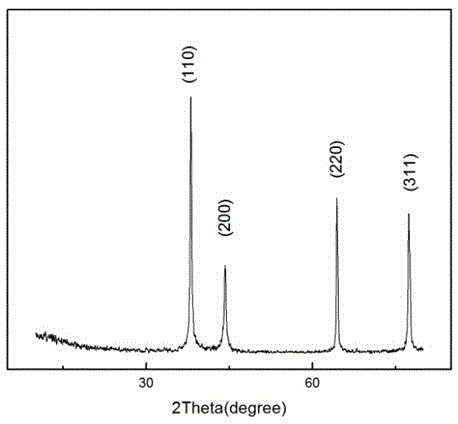

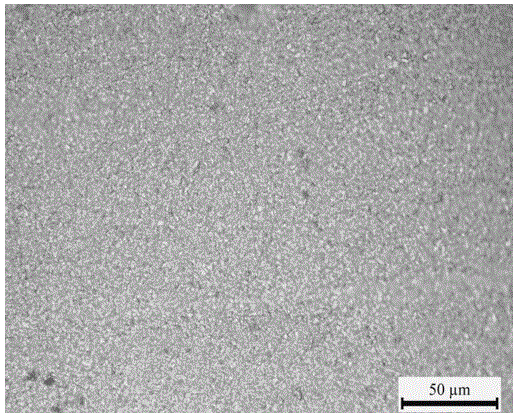

A cyanide-free silver plating and electroplating solution technology, which is applied in the field of cyanide-free silver plating, can solve the problems of poor stability and weak bonding force of the plating layer, and achieve the effect of fine grains, good stability of the plating solution, and a fine and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The cyanide-free silver plating solution described in this example is prepared from the following raw materials: silver tetrafluoroborate: 10g / L; methylpentynol 0.8g / L; 1,4-butynediol 0.5g / L; ammonium acetate 10g / L; anisaldehyde 20g / L; benzoic acid 10g / L; wherein the pH value of the cyanide-free silver plating solution is 3.

[0022] The cyanide-free silver plating solution prepared in this embodiment is used for electroplating, with the silver plate as the anode, and the piece to be plated (taking copper as an example) as the cathode, and its specific implementation method is as follows:

[0023] (1) Degreasing, pickling, water washing, chemical polishing, water washing, silver immersion, water washing and then drying the copper substrate once; the chemical polishing uses nitric acid, sulfuric acid, sodium chloride solution, the concentration is 30% nitric acid, 60% sulfuric acid , sodium chloride 4g / L.

[0024] (2) Connect the treated copper substrate and the anode o...

Embodiment 2

[0027] The cyanide-free silver plating solution described in this example is prepared from the following raw materials: silver tetrafluoroborate: 20g / L; methylpentynyl alcohol 0.1g / L; 1,4-butynediol 0.8g / L; ammonium acetate 14g / L; anisaldehyde 7g / L; benzoic acid 16g / L; wherein the pH value of the cyanide-free silver plating solution is 5.

[0028] The cyanide-free silver plating solution prepared in this embodiment is used for electroplating, with the silver plate as the anode, and the piece to be plated (taking copper as an example) as the cathode, and its specific implementation method is as follows:

[0029] (1) Degreasing, pickling, water washing, chemical polishing, water washing, silver immersion, water washing and then drying the copper substrate once; the chemical polishing uses nitric acid, sulfuric acid, sodium chloride solution, the concentration is 30% nitric acid, 60% sulfuric acid , sodium chloride 4g / L.

[0030] (2) Connect the treated copper substrate and the ...

Embodiment 3

[0032] The cyanide-free silver plating solution described in this example is prepared from the following raw materials: silver tetrafluoroborate: 40g / L; methylpentynyl alcohol 1.2g / L; 1,4-butynediol 1.2g / L; ammonium acetate 18g / L; anisaldehyde 12g / L; benzoic acid 20g / L; wherein the pH value of the cyanide-free silver plating solution is 4.

[0033] The cyanide-free silver plating solution prepared in this embodiment is used for electroplating, with the silver plate as the anode, and the piece to be plated (taking copper as an example) as the cathode, and its specific implementation method is as follows:

[0034] (1) Degreasing, pickling, water washing, chemical polishing, water washing, silver immersion, water washing and then drying the copper substrate once; the chemical polishing uses nitric acid, sulfuric acid and sodium chloride solution, the concentration of which is 28% nitric acid and 60% sulfuric acid , sodium chloride 4g / L.

[0035] (2) Connect the treated copper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com