Online detecting method and device of SCR urea nozzle faults

The technology of a urea nozzle and a detection method is applied to the electronic control of the exhaust gas treatment device, the diagnosis device of the exhaust gas treatment device, the exhaust gas treatment and other directions, which can solve the problems of urea leakage and crystallization, reduce the crystallization phenomenon and improve the reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

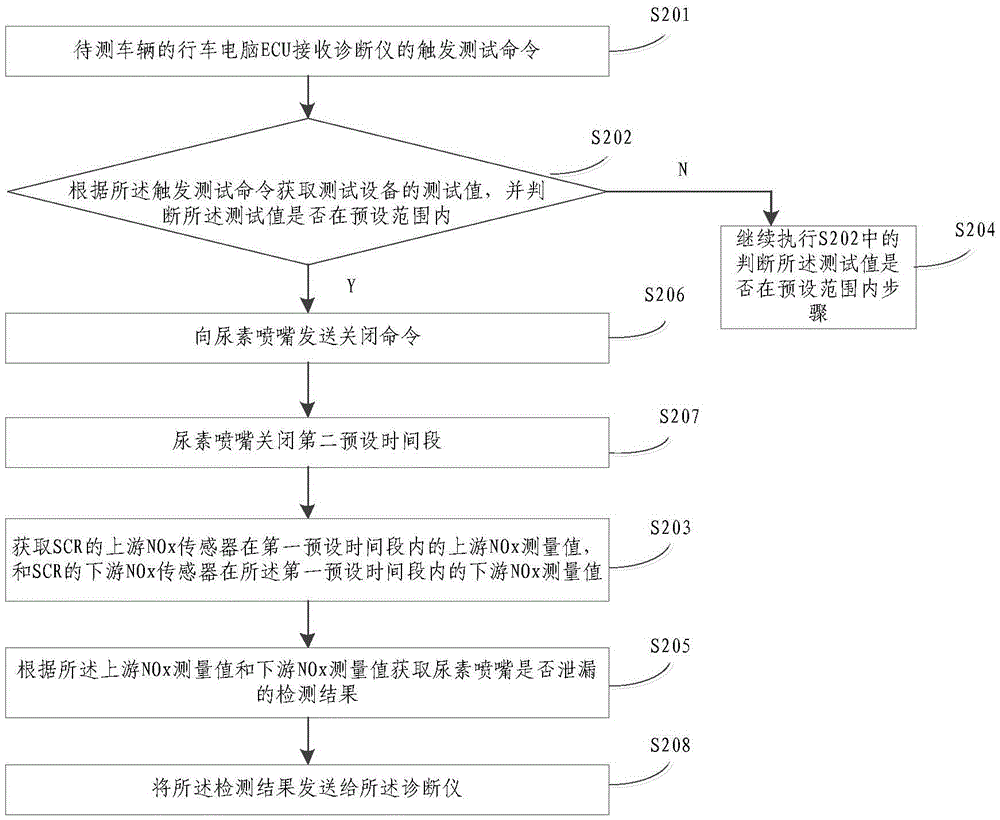

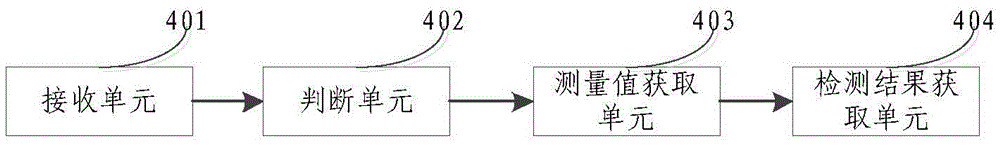

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0043] Interpretation of terms involved in the present invention:

[0044] NOx: Nitrogen oxides, mainly including nitric oxide NO and nitrogen dioxide NO2.

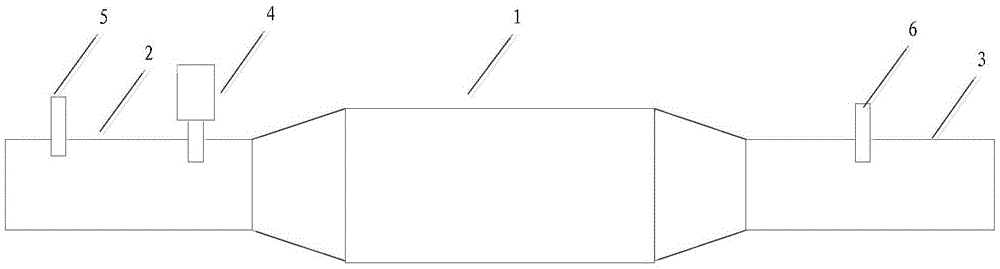

[0045] SCR: Selective catalytic reduction system, using urea to decompose to produce ammonia, ammonia reacts with NOx under the action of a catalyst to reduce NOx emissions.

[0046] EEPROM: The area in the ECU used to store certain variables after power-off, and the variables stored in this area can be read from the last stored value after power-on.

[0047] NH3: Ammonia, the input of the SCR system is used to reduce NOx, which is toxic and strictly controlled by emission regulations.

[0048] NOx sensor: A sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com