Apparatus and method for controlling a linear compressor and a linear compressor and a refrigerator having the same

A technology of linear compressors and control devices, which is applied to parts of pumping devices for elastic fluids, electromechanical devices, and mechanical energy control, and can solve the problems of increasing losses between cylinders and pistons, reducing efficiency, and reducing maximum refrigeration capacity. minor issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

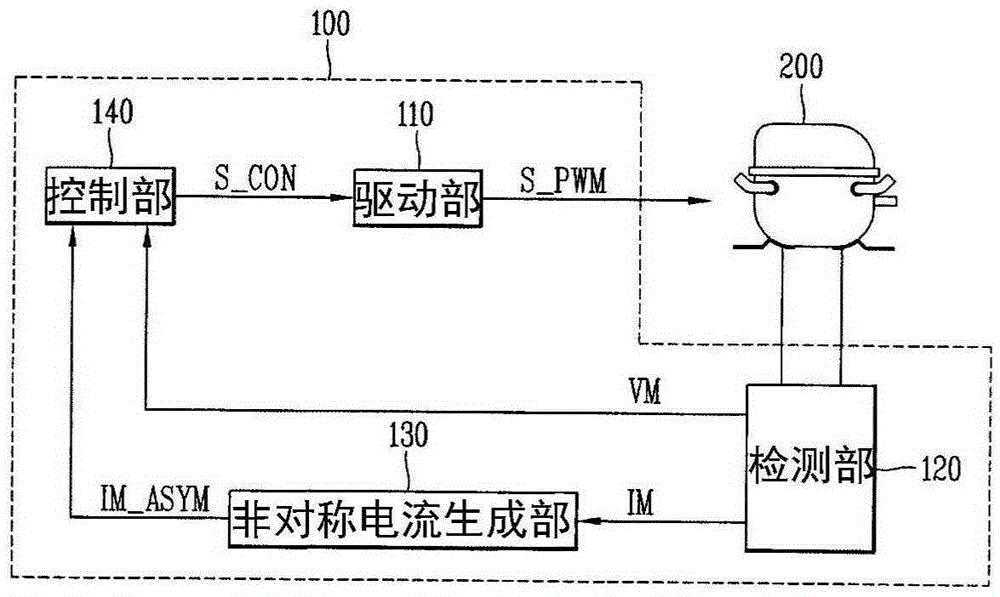

[0119] image 3 It is a configuration diagram of a linear compressor control device according to an embodiment of the present invention.

[0120] like image 3 As shown, the linear compressor control device 100 according to an embodiment of the present invention includes: a driving part 110, which drives the linear compressor 200 based on a control signal, and a detection part 120, which detects the motor current corresponding to the motor of the linear compressor 200 and / or the motor voltage, the asymmetric current generating unit 130 generates an asymmetric motor current by using a current offset in the detected motor current, and the control unit 140 generates an asymmetric motor current based on the asymmetric motor current and / or The sensed motor voltage generates the control signal; wherein the current offset is variable based on a change in piston position.

[0121] image 3 The structural elements of the linear compressor control shown are not mandatory, and a linea...

no. 2 example

[0241] This embodiment can be realized by a part or combination of the structures or steps included in the foregoing or subsequent embodiments. In order to clarify the description of this embodiment, repeated parts can be replaced by it and the detailed description is omitted.

[0242] The control device of the linear compressor in this embodiment may include: a driving part 110, which drives the linear compressor based on a control signal, a detection part 120, which detects the motor current and / or motor voltage of the linear compressor, and an asymmetric current generating part 130. Generate an asymmetric motor current by utilizing a current offset in the detected motor current, and the control unit 140 generates the asymmetric motor current based on the asymmetric motor current and / or the detected motor voltage. A control signal; wherein the current offset is variable based on a change in piston position.

[0243]According to an embodiment of the present invention, the cur...

no. 3 example

[0288] This embodiment can be realized by a part or combination of the structures or steps included in the foregoing or subsequent embodiments. In order to clarify the description of this embodiment, repeated parts can be replaced by it and the detailed description is omitted.

[0289] According to this embodiment, the current offset used by the asymmetrical current generator 130 in the motor current can be changed according to the operation mode of the linear compressor.

[0290] In this case, the operation mode may be at least one of a symmetrical control mode, an asymmetrical control mode, and a reverse asymmetrical control mode.

[0291] As an example, the symmetrical control mode is a mode for improving efficiency, and can be regarded as a high-efficiency mode. Furthermore, the symmetrical control mode is a mode in which relatively low load or low cooling capacity operation is performed compared with the above-mentioned asymmetrical control mode, and can be regarded as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com