Novel connecting method for pipelines with different pipe diameters and made of different materials

A new method and material technology, applied in the direction of pipes/pipe joints/fittings, passing components, mechanical equipment, etc., can solve problems such as poor water flow, damage to the environment, leakage, etc., to prevent sewage leakage, high safety and good The effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

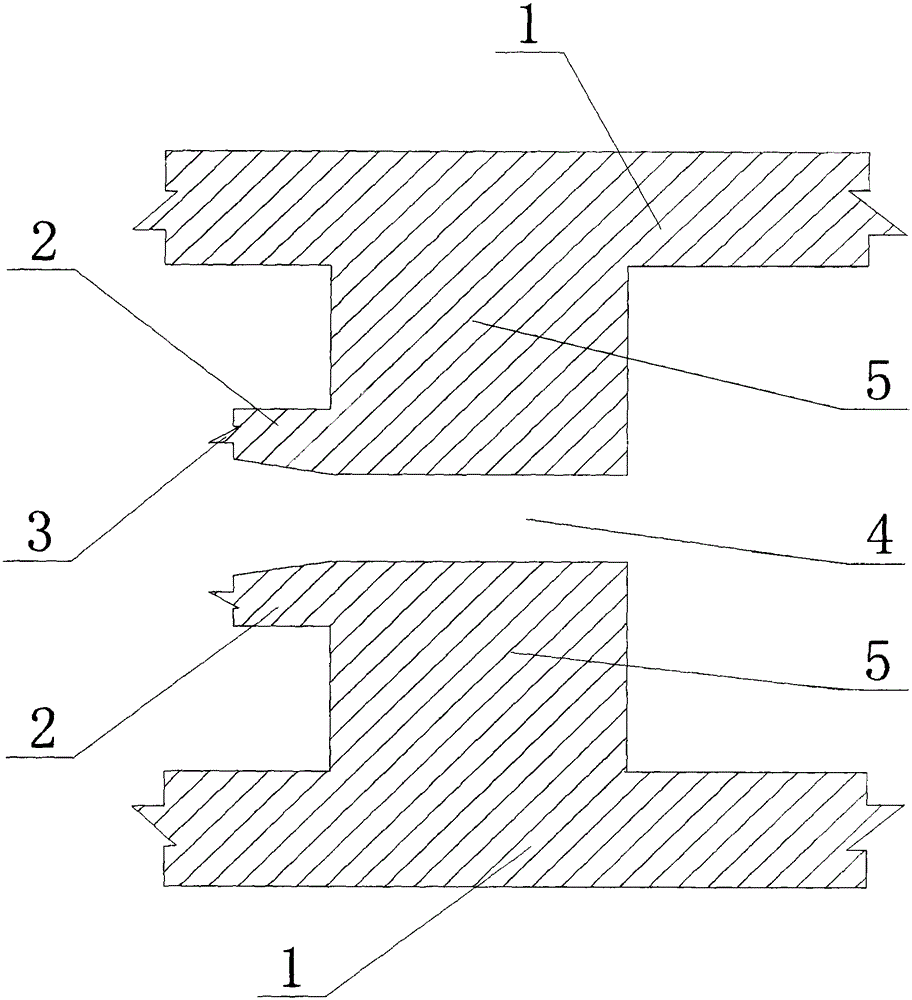

[0017] Such as figure 1 As shown, the new method for connecting pipes of different pipe diameters and materials includes a connecting device. The connecting device includes symmetrically arranged branch hole linings 1, and a blocking plate 5 is arranged between the branch hole linings 1, and a connecting plate is arranged in the middle of the blocking plate 5. Pipe 4, the connecting pipe 4 is provided with a connecting steel pipe. The branch tunnel lining 1, the blocking plate 5 and the connecting pipe are made by one-time pouring of concrete. The ends of the connecting steel pipes are pre-embedded with waterproof casings 3 . A section of steel pipe with a flange is installed at the end of the connecting steel pipe. The waterproof casing 3 is a steel waterproof casing, and a wing ring is arranged on the steel waterproof casing.

[0018] The new method of connecting pipes of different diameters and materials is to use the above-mentioned connecting device, and the steps are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com