Strong heat dissipation structure used for heat dissipation of laser television and preparation method thereof

A technology of heat dissipation structure and laser TV, which is applied to the parts of color TV, parts of TV system, TV, etc., can solve the problems of unstable laser display system, performance degradation of electronic components, low heat dissipation efficiency and power, and achieve The dust removal effect is good, the heat dissipation efficiency is improved, and the heat transfer uniformity is ensured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

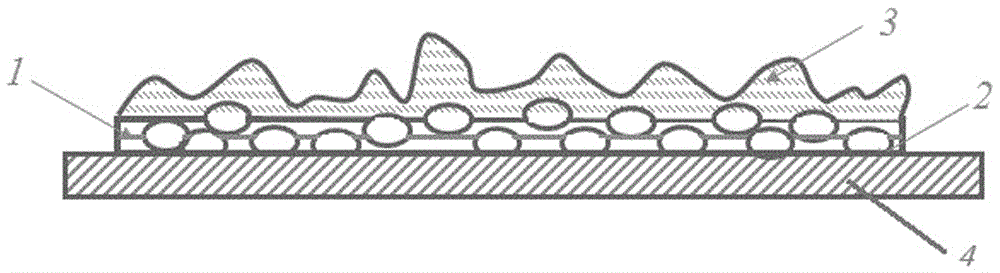

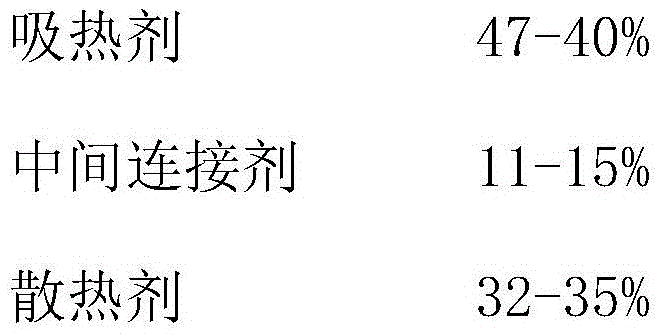

[0039] Such as figure 1 For the strong heat dissipation film shown, the total thickness of the strong heat dissipation film is 20 μm, the heat absorbing agent is silver nanospheres, the intermediate linker is graphene oxide, the heat dissipation agent is silver nanowires, and the protective agent is 0.2% polyether Diatom mud of modified polysiloxane. The weight percentage of the raw material composition of described strong heat dissipation film is:

[0040]

[0041]

[0042] The preparation method of the strong heat dissipation structure for laser TV heat dissipation is as follows:

[0043] (1) Clean the radiator or the substrate of the surface to be sprayed first, respectively use detergent, acetone, deionized water, and isopropanol to perform ultrasonic cleaning, dry it with dry nitrogen after cleaning, and then perform oxygen plasma bombardment treatment to ensure Good adhesion to the membrane;

[0044] (2) The surface of the substrate treated in step (1) is sprayed ...

Embodiment 2

[0052] like figure 1 For the strong heat dissipation film shown, the total thickness of the strong heat dissipation film is 20 μm, the heat absorbing agent is silver nanospheres, the intermediate linker is graphene oxide, the heat dissipation agent is silver nanowires, and the protective agent is 0.2% polyether Diatom mud of modified polysiloxane. The weight percentage of the raw material composition of described strong heat dissipation film is:

[0053]

[0054] The preparation method is as follows:

[0055] (1) Clean the radiator or the substrate of the surface to be sprayed first, respectively use detergent, acetone, deionized water, and isopropanol to perform ultrasonic cleaning, dry it with dry nitrogen after cleaning, and then perform oxygen plasma bombardment treatment to ensure Good adhesion to the membrane;

[0056] (2) The surface of the substrate treated in step (1) is sprayed with a water-soluble dispersion of absorbent silver nanospheres at a concentration o...

Embodiment 3

[0064] like figure 1 For the strong heat dissipation film shown, the total thickness of the strong heat dissipation film is 20 μm, the heat absorbing agent is silver nanospheres, the intermediate linker is graphene oxide, the heat dissipation agent is silver nanowires, and the protective agent is 0.2% polyether Diatom mud of modified polysiloxane. The weight percentage of the raw material composition of described strong heat dissipation film is:

[0065]

[0066] The preparation method is as follows:

[0067] (1) Clean the radiator or the substrate of the surface to be sprayed first, respectively use detergent, acetone, deionized water, and isopropanol to perform ultrasonic cleaning, dry it with dry nitrogen after cleaning, and then perform oxygen plasma bombardment treatment to ensure Good adhesion to the membrane;

[0068] (2) The surface of the substrate treated in step (1) is sprayed with a water-soluble dispersion of absorbent silver nanospheres with a concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com