Preparation method of menthol inclusion compound

A technology of menthol and clathrates, applied in the field of clathrates, can solve the problems of poor solubility of menthol and clathrates, long cladding time of preparation methods, low bioavailability, etc., shorten clathrate time and reduce drug particle size , Improve the effect of inclusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

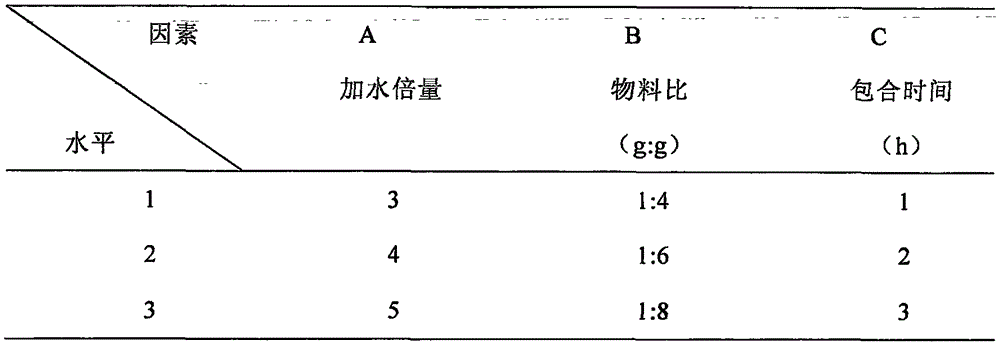

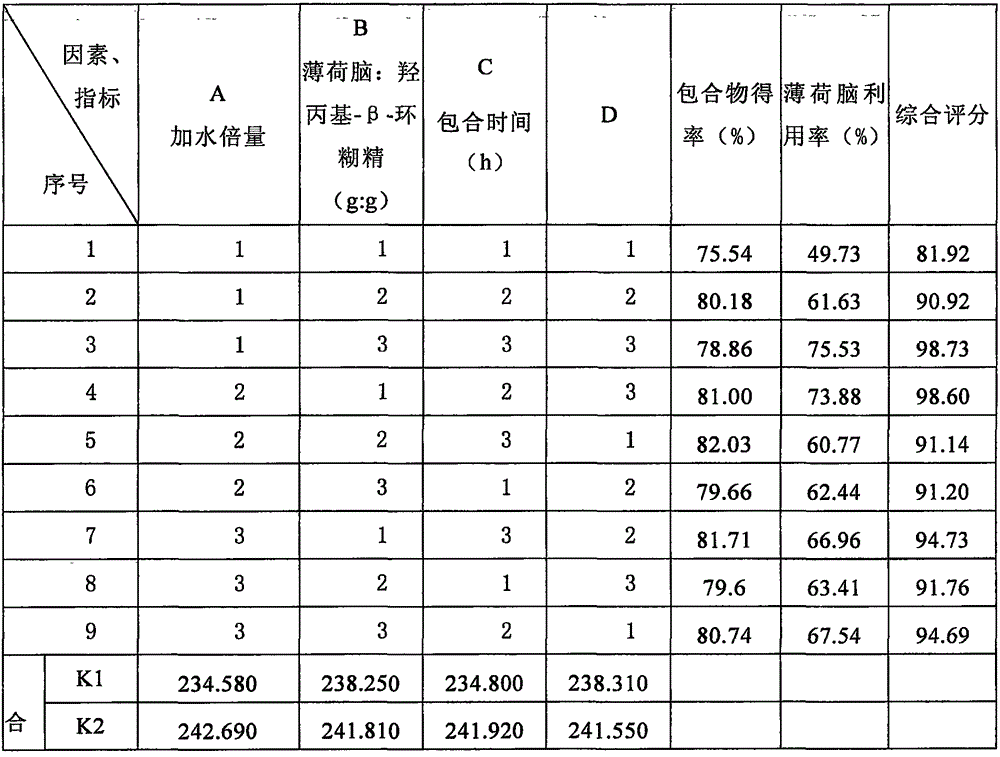

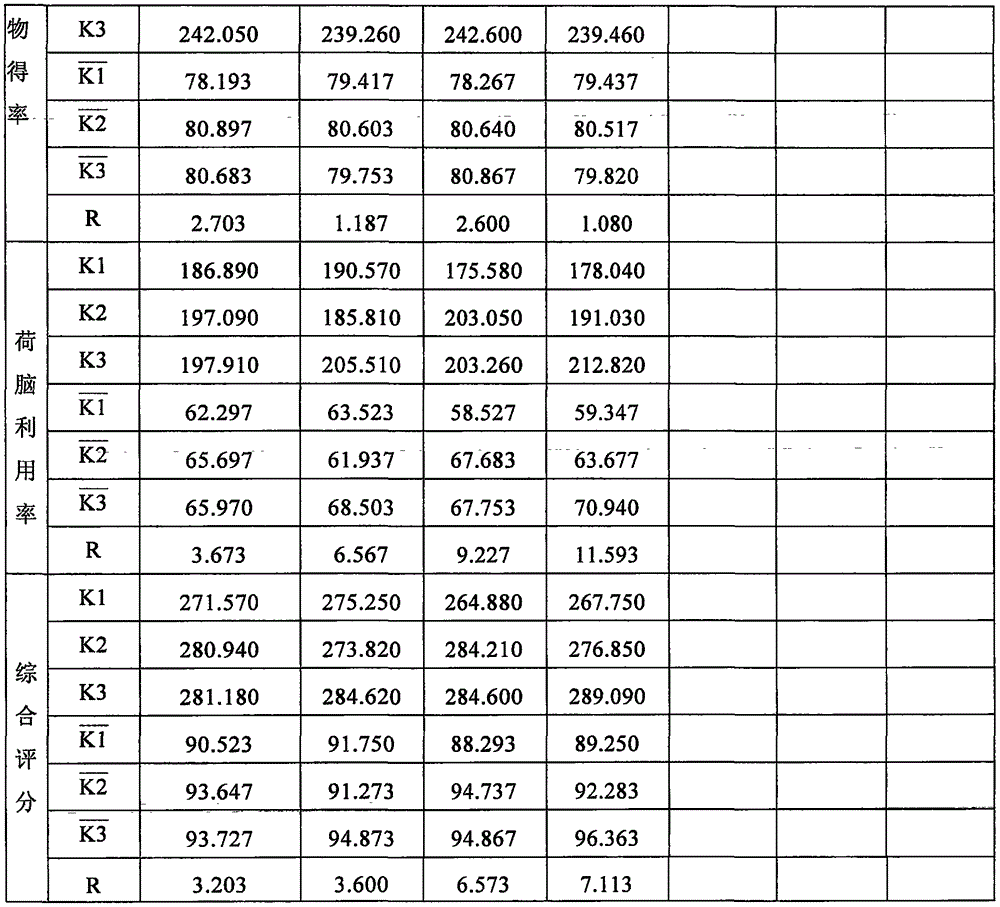

Method used

Image

Examples

Embodiment 1

[0050](1) Weigh hydroxypropyl-β-cyclodextrin with 6 times the weight of menthol, add water with 5 times the weight of hydroxypropyl-β-cyclodextrin, put it in an ultrasonic cleaner, mix evenly, and make hydroxypropyl-β-cyclodextrin A saturated aqueous solution of β-cyclodextrin. Weigh 5g of menthol ultrafine powder (ultrafinely pulverized to a particle size of 5 μm, accounting for more than 90%), slowly add it to the above saturated aqueous solution, start timing after all the addition, ultrasonic inclusion compound and cyclopaste after 20min The refined mixed solution was placed at 4°C for 24 hours, poured into a Buchner funnel, and filtered with suction. When there were no more drops, pour the clathrate and filter paper into an evaporating dish, and place it at 40°C. Vacuum-dry to dryness to obtain menthol hydroxypropyl-β-cyclodextrin inclusion compound, the inclusion rate of menthol is 67.88%.

[0051] (2) Weigh 2.0 g of the menthol inclusion compound prepared above, weigh ...

Embodiment 2

[0053] (1) Weigh hydroxypropyl-β-cyclodextrin with 8 times the weight of menthol, add water with 5 times the weight of hydroxypropyl-β-cyclodextrin, put it in an ultrasonic cleaner, mix evenly, and make hydroxypropyl-β-cyclodextrin For the saturated aqueous solution of propyl-β-cyclodextrin, weigh 5g of menthol superfine powder (the particle size is 5 μm and account for more than 90%), slowly add it to the above saturated aqueous solution, start timing after all the addition, and ultrasonically clathrate for 60 minutes Finally, put the mixed solution of inclusion compound and cyclodextrin at 4°C for 24 hours, pour it into a Buchner funnel, and filter it with suction. When there are no more drops, pour the inclusion compound and filter paper together. In an evaporating dish, vacuum-dry to dryness at 40° C. to obtain a menthol hydroxypropyl-β-cyclodextrin inclusion compound, and the inclusion rate of menthol is 82.88%.

[0054] (2) Weigh 2.0 g of the menthol inclusion compound p...

Embodiment 3

[0056] (1) Weigh hydroxypropyl-β-cyclodextrin with 6 times the weight of menthol, add water with 5 times the weight of hydroxypropyl-β-cyclodextrin, put it in an ultrasonic cleaner, mix evenly, and make hydroxypropyl-β-cyclodextrin Based on the saturated aqueous solution of β-cyclodextrin, weigh 5g of menthol superfine powder (the particle size is 5 μm and account for more than 90%), slowly add it to the above saturated aqueous solution, start timing after all the addition, and ultrasonic inclusion after 40min Put the mixed solution of clathrate and cyclodextrin at 4°C for 24 hours, pour it into a Buchner funnel, and filter it with suction. When there are no more drops, pour clathrate and filter paper together. In an evaporating dish, vacuum-dry to dryness at 40° C. to obtain menthol hydroxypropyl-β-cyclodextrin inclusion compound, and the inclusion rate of menthol is 71.69%.

[0057] (2) Weigh 2.0 g of the menthol inclusion compound prepared above, weigh it accurately, wash w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com