Method for preparing plate-like basic magnesium carbonate by template-induced/homogeneous precipitation

A homogeneous precipitation and magnesium carbonate technology, which is applied in the field of fire protection and materials, can solve the problems of complicated preparation methods, restrictions on the application of basic magnesium carbonate, agglomeration, etc., and achieve the effects of reducing safety hazards, good flame retardancy, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Weigh 2.0714g of MgCl 2 ·6H 2 O (purity: 98%) was dissolved in 25 ml of distilled water, and 0.5 mol / L dilute hydrochloric acid was added dropwise until pH=3.

[0024] 2. Weigh 1.212g of urea (purity: 99%) and 0.2071g of tetrahydrofuran, and dissolve them in the above solution.

[0025] 3. Transfer the solution obtained above to the reaction kettle, and pour a small amount of distilled water after rinsing the beaker into the reaction kettle.

[0026] 4. After sealing the reaction kettle, put it into a constant temperature water bath at 100°C, react for 8 hours, age for 5 hours, vacuum filter, and dry at 90°C for 4 hours to obtain plate-shaped basic magnesium carbonate.

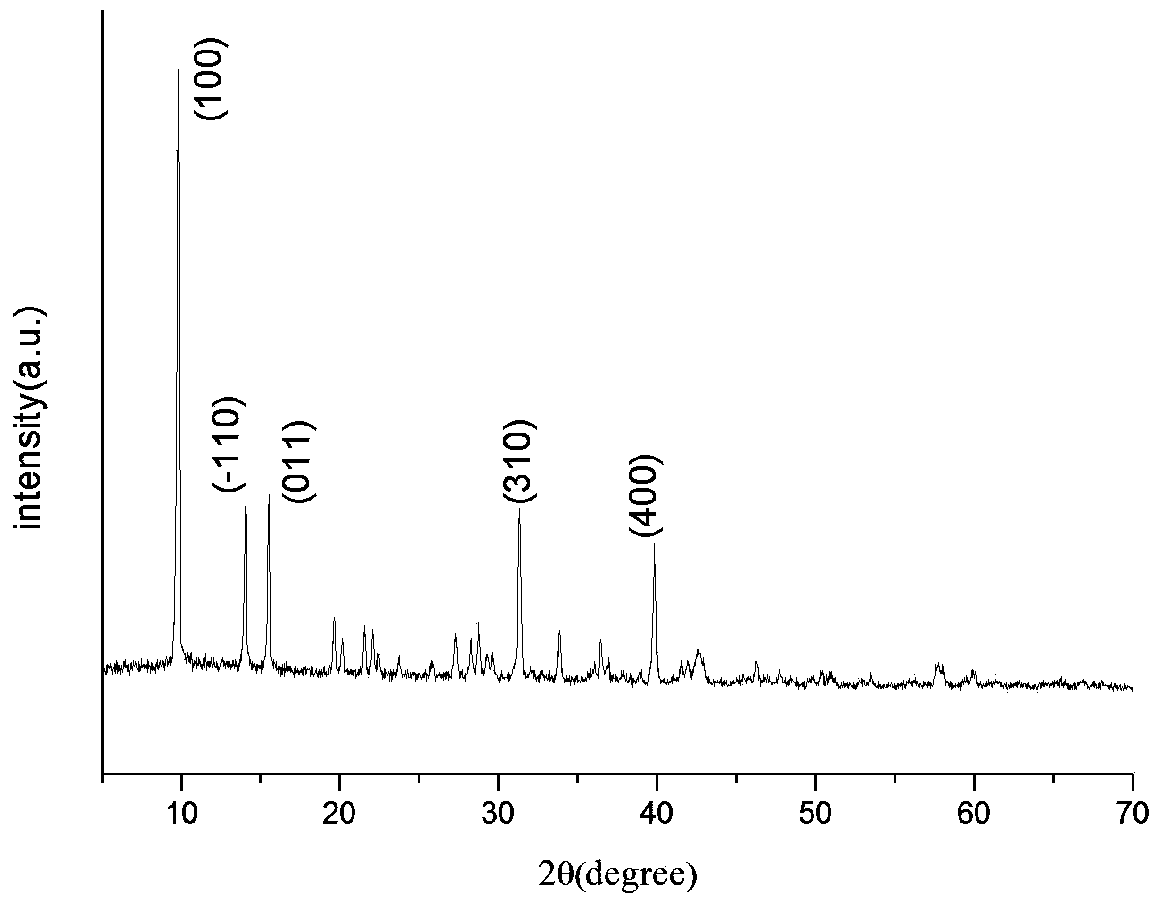

[0027] Plate-shaped Mg prepared under the above conditions 5 (CO 3 ) 4 (OH) 2 4H 2 The XRD diffraction pattern of O is shown in figure 1 . By comparing with the standard PDF card, the peak position and relative signal intensity of the sample are basically consistent with the standard diffrac...

Embodiment 2

[0029] 1. Weigh 3.6250g of MgCl 2 ·6H 2 O (purity is 98%), add 25ml of distilled water to dissolve, add 0.5mol / L dilute hydrochloric acid drop by drop until pH=3;

[0030] 2. Weigh 3.1818g urea (99% purity) and 0.3625g dimethyl sulfoxide, and dissolve them in the above solution;

[0031] 3. Transfer the solution obtained above to the reactor, and pour a small amount of distilled water after rinsing the beaker into the reactor;

[0032] 4. After sealing the reaction kettle, put it into a constant temperature water bath at 100°C, react for 16 hours, age for 5 hours, vacuum filter, and dry at 90°C for 4 hours to obtain plate-shaped basic magnesium carbonate.

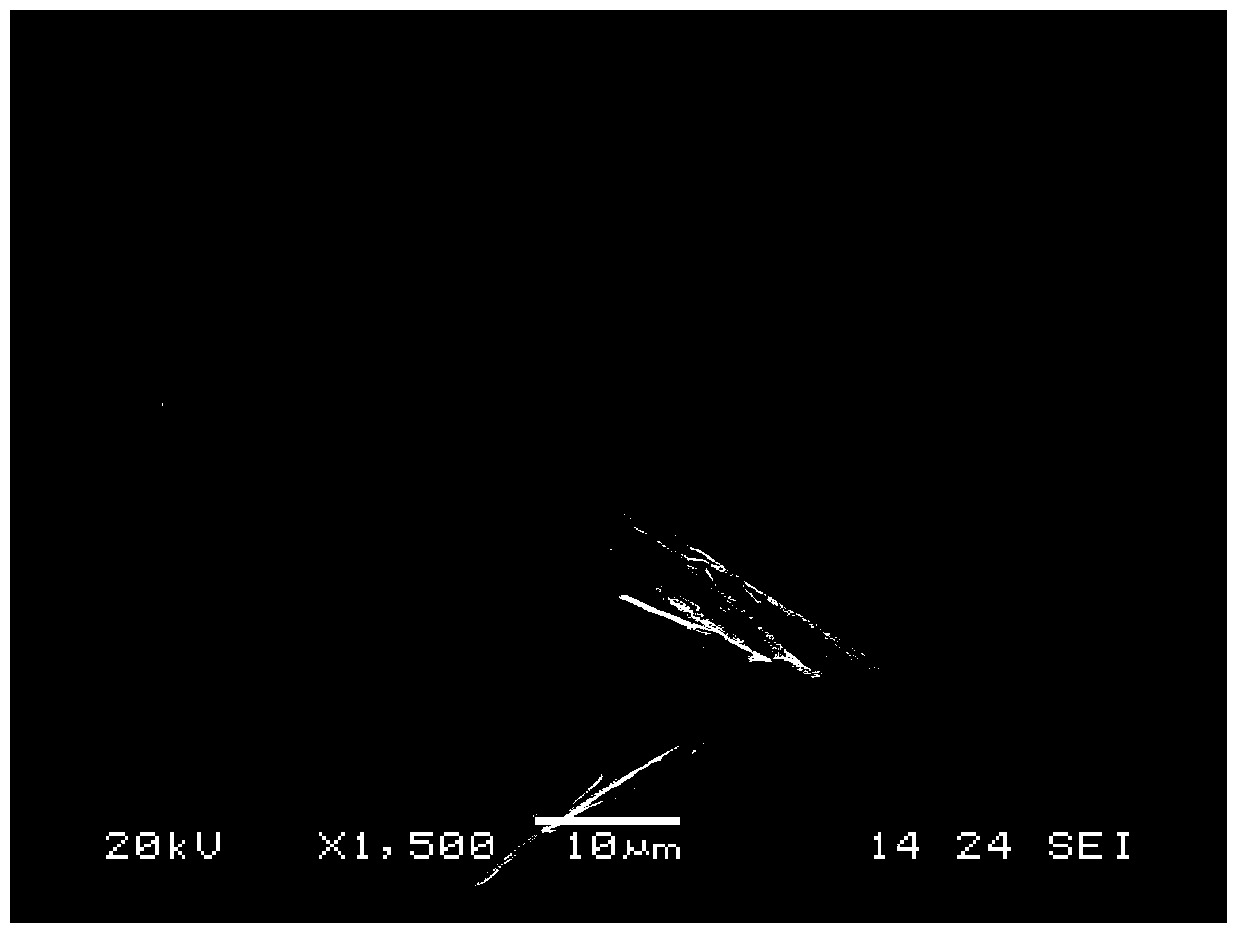

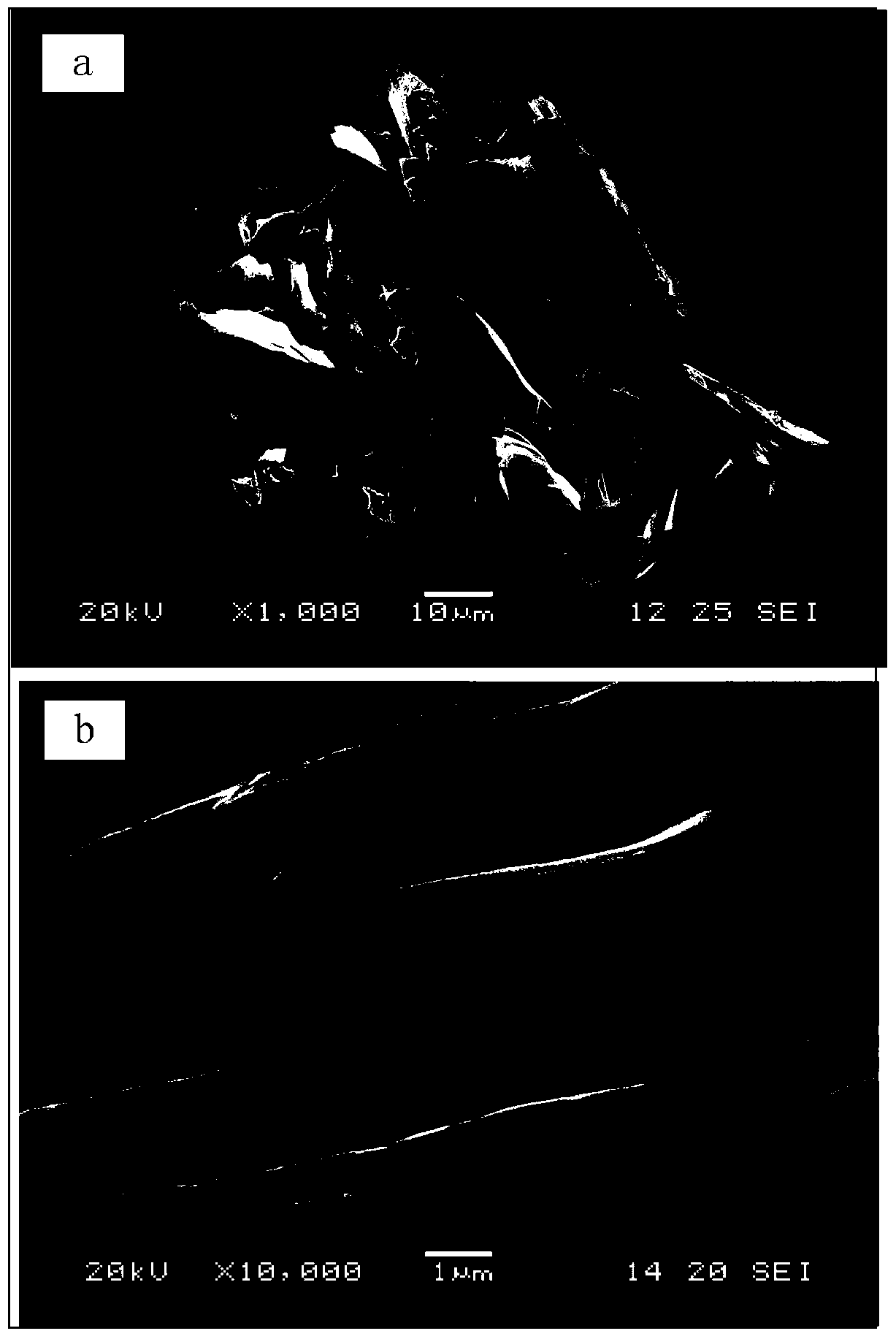

[0033] The Mg obtained in Example 2 5 (CO 3 ) 4 (OH) 2 4H 2 SEM photo of O ( image 3 a) with figure 2 There are obvious differences, but the photos under high magnification ( image 3 b) It can be seen from observation that the crystal is formed by stacking multi-layer sheets. The reason for this result is larg...

Embodiment 3

[0035] 1. Weigh 5.1786g of MgCl 2 ·6H 2 O (purity is 98%), add 25ml of distilled water to dissolve, add 0.5mol / L dilute hydrochloric acid drop by drop until pH=3;

[0036] 2. Weigh 6.0606g of urea (99% purity) and 0.5179g of ethylenediaminetetraacetic acid, and dissolve them in the above solution;

[0037] 3. Transfer the solution obtained above to the reactor, and pour a small amount of distilled water after rinsing the beaker into the reactor;

[0038] 4. After the reaction kettle is sealed, put it into a constant temperature water bath at 100°C, react for 24 hours, age for 5 hours, vacuum filter, and dry at 90°C for 4 hours to obtain plate-shaped basic magnesium carbonate.

[0039] from Figure 4 As can be seen from the shown SEM photographs, the flaky basic magnesium carbonate prepared under the conditions of Example 3, as time increases, the crystal growth is more complete, and the smoothness of the crystal plane is enhanced.

[0040] It can be seen from the above exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com