Bar frame sealed vacuum glass and manufacturing method thereof

A technology of vacuum glass and glass, which is applied in glass manufacturing equipment, glass production, glass molding, etc. It can solve the problems of difficulty in producing long-life, high-quality vacuum glass, affecting the light transmittance of vacuum glass, and complex structure of vacuum glass, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

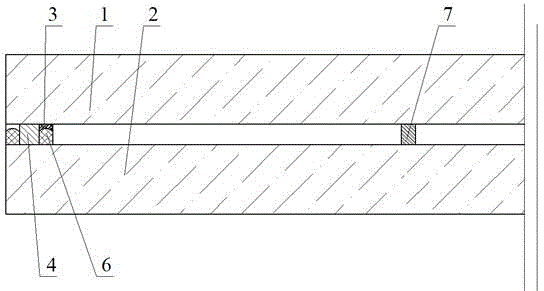

[0064] Embodiment 1: see figure 1, a two-layer sealed planar vacuum glass, two pieces of glass are tempered glass, one of which is still low-emissivity glass, and its production method is as follows: First, cut a piece of flat glass and a piece of flat glass according to the shape and size of the vacuum glass to be produced. Low-emissivity glass, and carry out edging, chamfering, cleaning and drying; secondly, prepare two edge banding strip frames 6 on the lower glass 2 with tempered glass ink and glue applicator, and then send the two pieces of glass into the tempering furnace respectively for Tempering treatment, the edge banding frame 6 is also sintered into one body with the lower glass 2; the support 7 is prepared by using polyimide adhesive and a dispensing machine again, and the support 7 is cylindrical, and the inner edge banding frame of the lower glass 2 6. Use a coating machine to evenly coat a layer of polyimide adhesive 3. Put low-temperature glass solder into the...

Embodiment 2

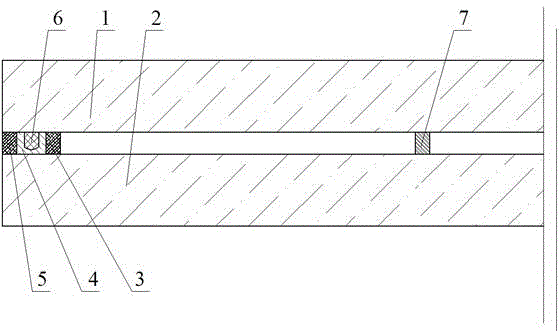

[0068] Example 2: see figure 2 , a three-way sealed planar vacuum glass with edge sealing strips, two pieces of glass are tempered glass, one of which is low-emissivity glass, and its production method is as follows: First, cut the required vacuum glass according to the shape and size of the vacuum glass to be produced. A piece of flat glass and a piece of low-emissivity glass of the same size, and carry out edge grinding, chamfering, cleaning, and drying; secondly, on the upper glass 1, use tempered glass ink and a dispenser to prepare edge banding frame 6 and support 7, support The object 7 is cylindrical, and then the two pieces of glass are respectively sent into a tempering furnace for tempering treatment, the prepared edge banding strip frame 6 and the support 7 are also sintered on the glass; the sintered support 7 is mechanically ground again , so that the top is in a plane, and the top edge after grinding is rounded to further eliminate the influence of stress; then ...

Embodiment 3

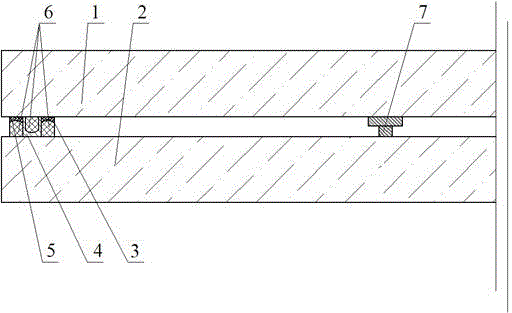

[0071] Embodiment 3: see image 3 , a three-sealing planar vacuum glass with edge sealing strips on the upper and lower glass. A piece of flat glass and a piece of low-emissivity glass of the required size are ground, chamfered, cleaned and dried; secondly, one and two seals are prepared on the upper glass 1 and the lower glass 2 respectively with tempered glass ink and glue applicator. The edge strip frame 6 and the edge strip frame 6 of the upper glass 1 correspond to between the two edge strip frames 6 of the lower glass 2, and then the two pieces of glass are respectively sent into a tempering furnace for tempering treatment, and the prepared edge strip The strip frame 6 is also sintered on the glass; the support 7 is prepared on the two pieces of glass with low-temperature glass solder and a glue dispenser again, and the support 7 is in the shape of a strip, and the upper and lower supports cross together after the two pieces of glass are combined; Then evenly coat the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com