Preparing method of beta,beta'-dithiobis(dihydrocinnamicacid)

A technology of dihydrocinnamic acid and disulfide, which is applied in the field of preparation of high-purity β,β'-disulfide, can solve the problems of complicated operation and difficult to guarantee yield, and achieves the effect of simple operation and reduction of side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

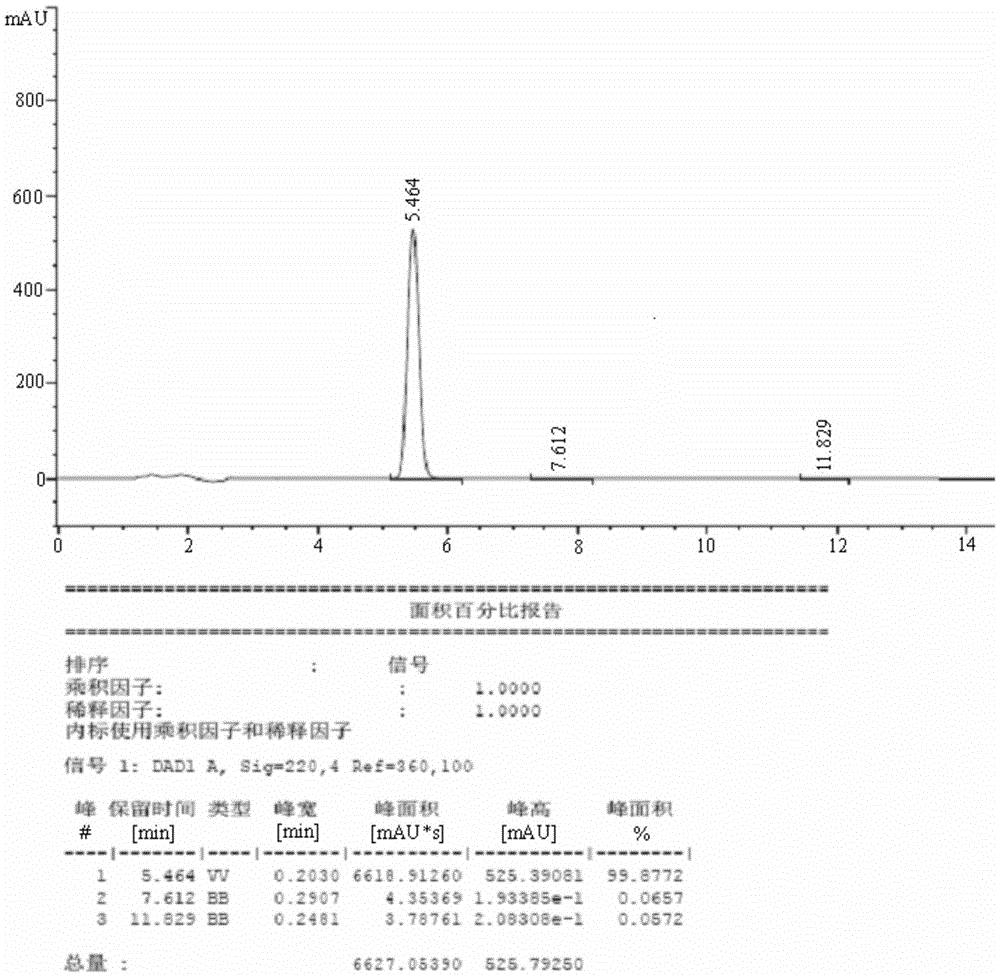

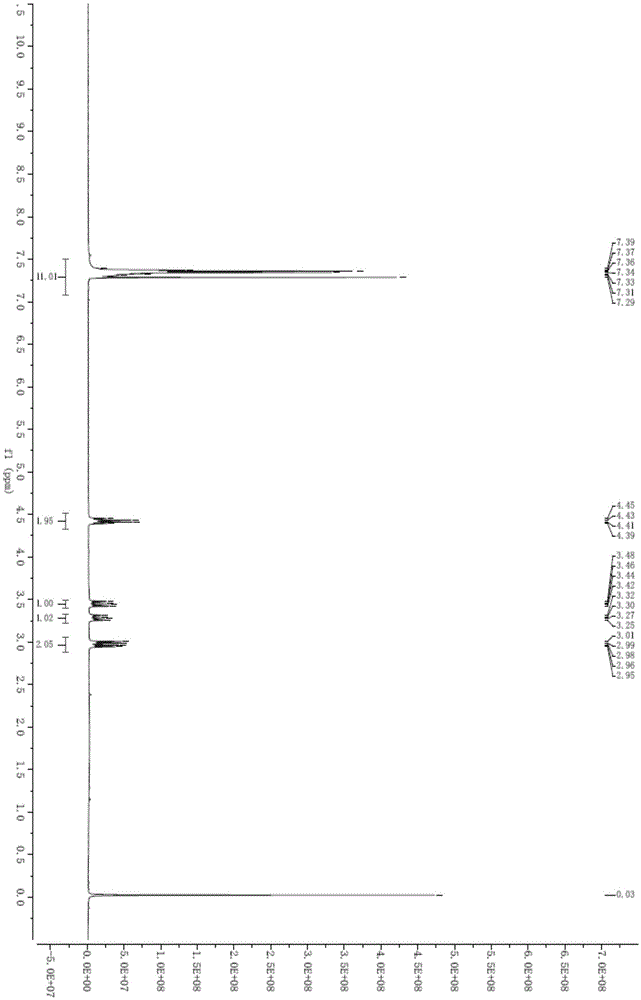

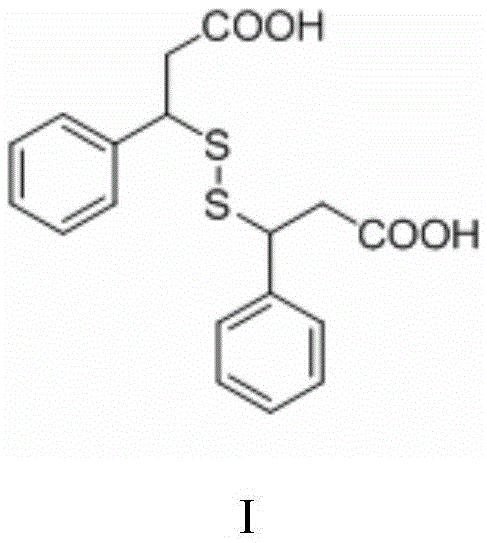

[0031] Add 36.4g of 3-mercapto-3-phenylpropionic acid (200mmol), 72mL of 2.8mol / L sodium hydroxide solution (NaOH200mmol), 0.1g of iodine, and 128g of water into a three-necked flask equipped with a stirrer thermometer. The temperature was lowered to 5° C., and 22.7 g of 30% hydrogen peroxide was added dropwise. Incubate for 1 h to complete the reaction. After the reaction, add 0.5 g of sodium bisulfite to quench, and add hydrochloric acid to adjust the pH to 3-5. After filtering and drying, 34 g of β, β'-dithiobis(dihydrocinnamic acid) was obtained, and the yield reached 94%. The obtained β, β'-dithiobis(dihydrocinnamic acid) is analyzed, and its liquid chromatography content is 99.88% (HPLC, in220nm), and the specific results are as follows figure 2 Shown, LCMS: 361[M-H] - ; H-NMR results such as figure 1 as shown, 1 HNMR (CDCl 3 ,400Hz)7.30-7.39(m,10H),4.39-4.45(dd,2H,J=8Hz),3.42-3.48(dd,1H,J=8Hz),3.25-3.32(dd,1H,J=8Hz) ,2.95-3.00(m,2H).

Embodiment 2

[0033] Add 36.4g of 3-mercapto-3-phenylpropionic acid (200mmol), 0.364g of barium oxide, and 200g of water into a three-necked flask equipped with a stirrer thermometer, and gradually add potassium carbonate to adjust the pH of the reaction solution to 8. The temperature was lowered to 10° C., and 172 g of a 13% sodium hypochlorite solution (300 mmol of sodium hypochlorite) was added dropwise. Incubate for 1 h to complete the reaction. After the reaction, add 0.5 g of sodium bisulfite to quench, and add hydrochloric acid to adjust the pH to 3-5. After filtering and drying, β,β'-dithiobis(dihydrocinnamic acid) was obtained, and the yield and identification results were similar to those of Example 1.

Embodiment 3

[0035] Add 36.4g of 3-mercapto-3-phenylpropionic acid (200mmol), 0.364g of iron oxide, and 75g of water into a three-necked flask equipped with a stirrer thermometer, and gradually add potassium hydroxide to adjust the pH of the reaction solution to 9. The temperature was lowered to 0° C., and 250 mmol of nitric acid (10% aqueous nitric acid solution was used) was added dropwise. Incubate for 1 h to complete the reaction. After the reaction, add 0.5 g of sodium bisulfite to quench, and add hydrochloric acid to adjust the pH to 3-5. After filtering and drying, β,β'-dithiobis(dihydrocinnamic acid) was obtained, and the yield and identification results were similar to those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com