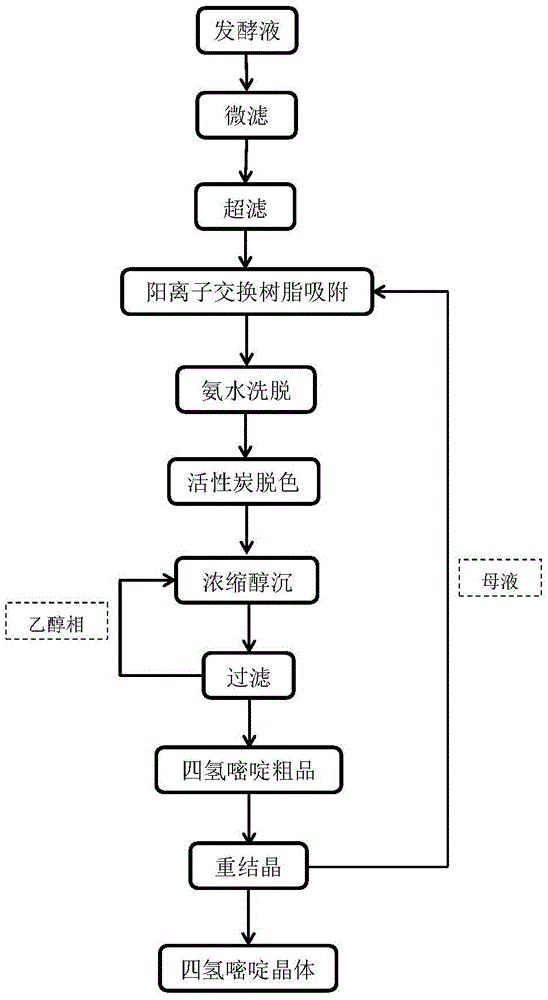

Method for separating and extracting tetrahydropyrimidine from fermentation broth

A technology of tetrahydropyrimidine and fermentation broth, applied in organic chemistry and other directions, can solve the problems of complex process route, high energy consumption and water consumption, difficult separation and purification, etc., and achieves high retention rate, low energy consumption, and improved recovery rate and purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a, get ectoine fermented liquid 5L (ectoline content 25.0g / L), regulate pH with the hydrochloric acid of 4mol / L and be 4.0, enter microfiltration membrane separation system, obtain the ectoine microfiltrate that removes thalline; The microfiltration membrane separation system uses a hollow fiber microfiltration membrane with a pore size of 0.02 μm, an operating temperature of 30° C., and an operating pressure of 0.2 MPa. Collect the filtrate, stop collecting when the concentration of ectoine in the filtrate is lower than 1.0g / L, and the cell removal rate is 99.2%.

[0029] b. Pump the microfiltrate obtained in step a into the ultrafiltration membrane separation system to obtain the ectoine ultrafiltrate from which protein and pigment have been removed. The ultrafiltration membrane separation system adopts a hollow fiber ultrafiltration membrane with a pore size of 0.003 μm, an operating temperature of 40° C., and an operating pressure of 0.3 MPa. The filtrate is collect...

Embodiment 2

[0036]a, get ectoine fermented liquid 5L (ectoline content 25.0g / L), regulate pH with the hydrochloric acid of 4mol / L and be 6.0, enter microfiltration membrane separation system, obtain the ectoine microfiltrate that removes thalline; The microfiltration membrane separation system uses a hollow fiber microfiltration membrane with a pore size of 0.05 μm, an operating temperature of 35° C., and an operating pressure of 0.15 MPa. Collect the filtrate, stop collecting when the concentration of ectoine in the filtrate is lower than 1.0g / L, and the bacterial cell removal rate is 97.4%.

[0037] b. Pump the microfiltrate obtained in step a into the ultrafiltration membrane separation system to obtain the ectoine ultrafiltrate from which protein and pigment have been removed. The ultrafiltration membrane separation system adopts a hollow fiber ultrafiltration membrane with a pore size of 0.01 μm, an operating temperature of 35° C., and an operating pressure of 0.1 MPa. The filtrate i...

Embodiment 3

[0044] a, get ectoine fermented liquid 5L (ectoline content 25.0g / L), regulate pH with 4mol / L hydrochloric acid and be 5.0, enter microfiltration membrane separation system, obtain the ectoine microfiltrate that removes thalline; The microfiltration membrane separation system described above adopts a hollow fiber microfiltration membrane with a pore size of 0.12 μm, an operating temperature of 45° C., and an operating pressure of 0.1 MPa. Collect the filtrate, stop collecting when the concentration of ectoine in the filtrate is lower than 1.0g / L, and the bacterium removal rate is 94.6%.

[0045] b. Pump the microfiltrate obtained in step a into the ultrafiltration membrane separation system to obtain the ectoine ultrafiltrate from which protein and pigment have been removed. The ultrafiltration membrane separation system adopts a hollow fiber ultrafiltration membrane with a pore size of 0.006 μm, an operating temperature of 25° C., and an operating pressure of 0.2 MPa. The fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com