Method for extracting and preparing DHA (docosahexaenoic acid) of algae oil

An algal oil and solvent extraction technology, which is applied in the direction of fat oil/fat refining, fat oil/fat production, and fat production, can solve the problems of low yield, backward preparation technology, low production efficiency, etc. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

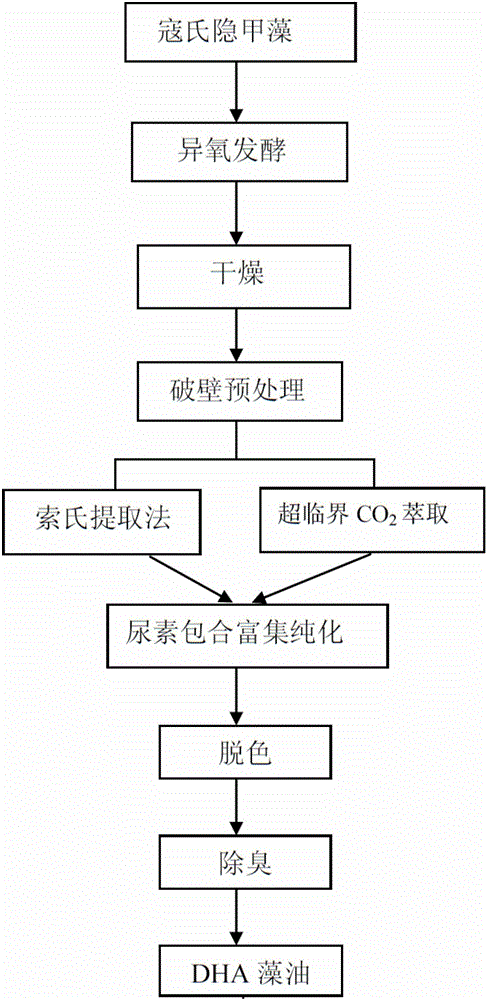

[0062] A method for extracting and preparing algae oil DHA disclosed by the invention comprises the following steps:

[0063] (1) cultivating and fermenting Cryptidium koushii; the culturing and fermenting are algae culturing and heterotrophic fermentation to obtain microalgae raw materials;

[0064] (2) drying; the microalgae raw material obtained in step (1) is dried to obtain microalgae powder;

[0065] (3) wall-breaking pretreatment; the microalgae powder obtained in step (2) is subjected to microalgae wall-breaking pretreatment by ultrasonic treatment to obtain microalgae dry powder;

[0066] (4) Microalgae DHA extraction; the microalgae dry powder obtained in step (3) is extracted by Soxhlet extraction method and / or supercritical carbon dioxide extraction method to obtain microalgae oil;

[0067] (5) urea inclusion enrichment and purification; the microalgae oil obtained in step (4) is enriched and purified by urea inclusion to purify DHA; obtain microalgae DHA algae oi...

specific Embodiment

[0102] In some embodiments, we have carried out specific examples of fermentation conditions, wherein temperature and pH values are controlled differently to obtain more preferred technical solution effects; specific examples are as follows:

[0103] (1) Embodiment about temperature:

[0104] The optimum temperature for microalgae growth and oil accumulation varies from species to species. After the secondary seeds are inserted into the fermentation medium, they are fermented at temperatures of 15°C, 20°C, 25°C, 30°C, and 35°C. The effects of different temperatures on the biomass and oil content of Cryptodinium algae were studied.

[0105] (2) Embodiment about pH value:

[0106] The initial pH value of the medium is one of the important factors affecting the growth rate of microalgae. Many researchers have found that various algae grow fastest around pH5-7, and it is difficult to grow under extremely acidic or alkaline conditions. The initial pH of the fermentation medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com