Mango vinegar, mango vinegar drink and preparation method thereof

A technology of mango vinegar and mango, which is applied in the field of mango beverage and its preparation, and mango vinegar, which can solve the problems of single strains and complicated methods, and achieve the effects of pure taste, increased content, and increased juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

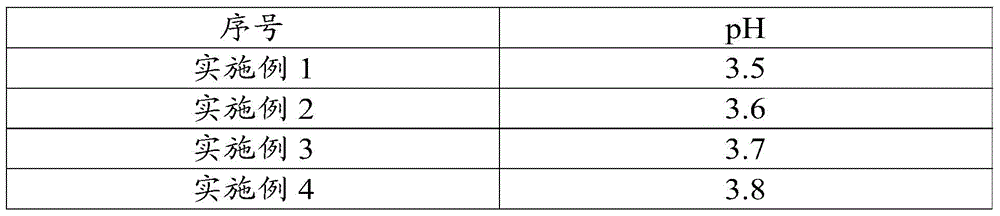

Embodiment 1

[0045] The preparation method of mango vinegar provided by the invention specifically comprises the following steps:

[0046] Mangoes are washed, peeled, watered, beaten, and filtered to obtain mango puree; water and pectinase are added to the mango puree for activation and decomposition, and then photosynthetic bacteria fermentation, yeast fermentation and acetic acid fermentation are carried out in sequence to obtain mangoes vinegar.

Embodiment 2

[0048] S21, washing fresh mangoes, peeling, adding water, beating, and filtering to obtain mango puree;

[0049] S22. Dilute the mango puree with water to obtain a mango puree with a sugar content of 8% and a pH of 5.0, then add pectinase with a mass of 3% of the mango puree, and activate and decompose the pectinase at 26°C for 6 hours; then add photosynthetic bacteria with 7% of the mass of the mango stock solution, and carry out photosynthetic bacteria fermentation at 26° C. for 4 days to obtain the first liquid.

[0050] S23. Add yeast to the first liquid, and pass through carbon dioxide, and carry out yeast fermentation at 26°C for 4 days to obtain a second liquid with an alcohol content of 6.0% and pH=3.5; add acetic acid to the second liquid bacterium, carried out acetic acid fermentation under the condition of 26 ℃ for 6 days, and filtered to obtain mango vinegar.

Embodiment 3

[0052] S31, same as step S21 in embodiment 2;

[0053] S32. Dilute the mango puree with water to obtain a mango puree with a sugar content of 12% and a pH of 6.0, then add pectinase with a mass of 5% of the mango puree, and activate and decompose the pectinase at 28°C for 8 hours; then add photosynthetic bacteria with 10% of the mass of the mango stock solution, and carry out photosynthetic bacteria fermentation at 28° C. for 5 days to obtain the first liquid.

[0054] S33. Add yeast to the first liquid, and pass in carbon dioxide, and carry out yeast fermentation at 28°C for 6 days to obtain a second liquid with an alcohol content of 6.5% and pH=4.5; add acetic acid to the second liquid bacterium, carried out acetic acid fermentation under the condition of 30 ℃ for 8 days, and filtered to obtain mango vinegar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com