Antibacterial anti-ultraviolet microcapsule finishing agent and preparation method thereof

A microcapsule finishing and anti-ultraviolet technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of human body harm, skin aging, burning skin, etc., and achieve the effect of good inhibition effect and good protection function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

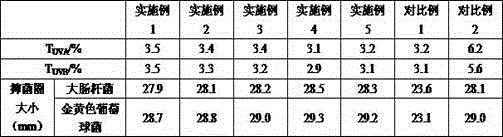

Examples

Embodiment 1

[0059] (1) Mix 2 parts of red nan leaf essential oil, 2 parts of juniper oil, 2 parts of 4-tert-butylphenyl salicylate, 2 parts of chitosan, 1 part of polyethylene glycol, 1 part of gardenia yellow, 0.1 part of crown fruit oil, 1 part of fatty alcohol polyoxyethylene ether, 0.1 part of betulinic acid, 0.1 part of arabitol, 1 part of lignocellulose, and 5 parts of isopropanol are mixed, and ball milled in a ball mill. The ball-to-material ratio in the ball mill 20:1, ball milling time is 1 hour;

[0060] (2) After taking out the grinding mixture, add 0.5 parts of xanthan gum and 30 parts of water, and stir for 20 minutes at the speed of a magnetic stirrer at 100 r / min;

[0061] (3) Mix 1-2 parts of gelatin and 30 parts of water, stir for 10 minutes at a temperature of 55°C and a stirring speed of 500r / min, and filter to remove impurities;

[0062] (4) Add the gelatin solution into the mixture in (2), and stir for 10 minutes at a temperature of 35°C and a stirring speed of 400r...

Embodiment 2

[0067] (1) 3 parts of red nan leaf essential oil, 3 parts of juniper oil, 3 parts of 4-tert-butylphenyl salicylate, 3 parts of chitosan, 1.4 parts of polyethylene glycol, 1.4 parts of gardenia yellow, 0.12 parts of crown fruit oil, 1.1 parts of fatty alcohol polyoxyethylene ether, 0.11 parts of betulinic acid, 0.12 parts of arabitol, 1.3 parts of lignocellulose, and 6 parts of isopropanol are mixed, and ball milled in a ball mill. The ball-to-material ratio in the ball mill is 25:1, and the ball milling time is 1.2 hours;

[0068] (2) After taking out the grinding mixture, add 0.7 parts of xanthan gum and 32 parts of water, and stir for 22 minutes at the speed of magnetic stirrer at 110r / min;

[0069] (3) Mix 1.4 parts of gelatin and 32 parts of water, stir for 12 minutes at a temperature of 58°C and a stirring speed of 600r / min, and filter to remove impurities;

[0070] (4) Add the gelatin solution into the mixture in (2), and stir for 12 minutes at a temperature of 38°C and a...

Embodiment 3

[0075] (1) 3.5 parts of red nan leaf essential oil, 3.5 parts of juniper oil, 3.5 parts of 4-tert-butylphenyl salicylate, 3.5 parts of chitosan, 1.5 parts of polyethylene glycol, 1.5 parts of gardenia yellow, Mix 0.15 parts of crown fruit oil, 1.5 parts of fatty alcohol polyoxyethylene ether, 0.15 parts of betulinic acid, 0.15 parts of arabitol, 1.5 parts of cellulose, and 7.5 parts of isopropanol, and ball mill in a ball mill. is 25:1, and the ball milling time is 1.5 hours;

[0076] (2) After taking out the grinding mixture, add 0.7 parts of xanthan gum and 35 parts of water, and stir for 25 minutes at a magnetic stirrer speed of 150r / min;

[0077] (3) Mix 1.5 parts of gelatin and 35 parts of water, stir for 15 minutes at a temperature of 55-65°C and a stirring speed of 650r / min, and filter to remove impurities;

[0078] (4) Add the gelatin solution into the mixture in (2), and stir for 15 minutes at a temperature of 40°C and a stirring speed of 500 r / min after ultrasonic o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com