Rock wool composite board and continuous production method thereof

A production method and composite panel technology, applied in chemical instruments and methods, layered products, building components, etc., can solve the problems of low production efficiency, complex production process, high cost, etc., and achieve safe and reliable performance and simple and easy process , The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

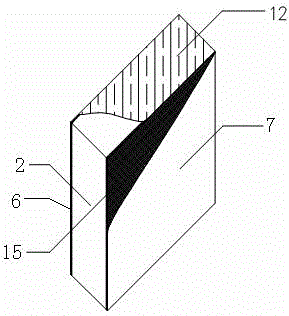

[0033] In this embodiment, the rock wool composite board includes the upper coil layer 7 and the lower coil layer 6, which use non-woven fabric as the base material, and play the role of reinforcement and fire prevention, and are compounded between the upper coil layer 7 and the lower coil layer 6. The rock wool board 2 with a thickness of 5 cm for heat preservation, the upper coiled material layer 7 and the rock wool board 2 and the lower coiled material layer 6 and the rock wool board 2 are all combined into one through the adhesive layer 15 . Both the upper coil layer 7 and the lower coil layer 6 are purchased from Jinan Ouxin New Material Company.

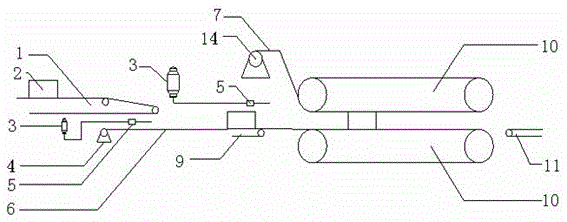

[0034] The continuous production equipment of the rock wool composite board of the present embodiment comprises a rock wool conveying table 1 for conveying the rock wool board 2, a lower coil layer uncoiler 4 for uncoiling the lower coil layer 6, a The lower glue spraying mechanism reciprocates and evenly sprays glue on the upp...

Embodiment 2

[0038] The difference between this embodiment and Example 1 is that a waterproof coating 12 is provided around the rock wool composite board, and the waterproof coating includes the following raw materials in parts by mass: 30-40 parts of petroleum asphalt, 0.3-40 parts of polyoxypropylene glycol 0.6 parts, 3-8 parts of nano-titanium dioxide, 1-4 parts of epoxy resin, 35-37 parts of water, 0.5-1 part of pH regulator.

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 or 2 is that the base materials of the upper coiled material layer 7 and the lower coiled material layer 6 are glass fibers, the thickness of the rock wool board 2 is 4 cm, and the arrangement of the rock wool board 2 is The vertical wires are arranged, the fiber direction of the rock wool board 2 is the same as the thickness direction of the rock wool composite board, and the fiber direction of the rock wool board 2 is perpendicular to the length direction or width direction of the rock wool composite board;

[0041] The specific operation steps of its production process are:

[0042]Control the linkage speed of rock wool conveying table 1, lower coil uncoiler 4, upper coil uncoiler 14, front conveying table 9, and double-track laminator system 10 to 20m / min, set the lower glue spraying mechanism and the upper spraying mechanism The gun head 5 of the glue spraying mechanism has a gun head pressure of 15MPa, an adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com