Index gas based goaf coal spontaneous combustion hazard level judgment and prewarning method

A technology of dangerous degree and goaf, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of spontaneous combustion, low reliability, high cost, etc., and achieve comprehensive and accurate prediction, novel and reasonable design, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

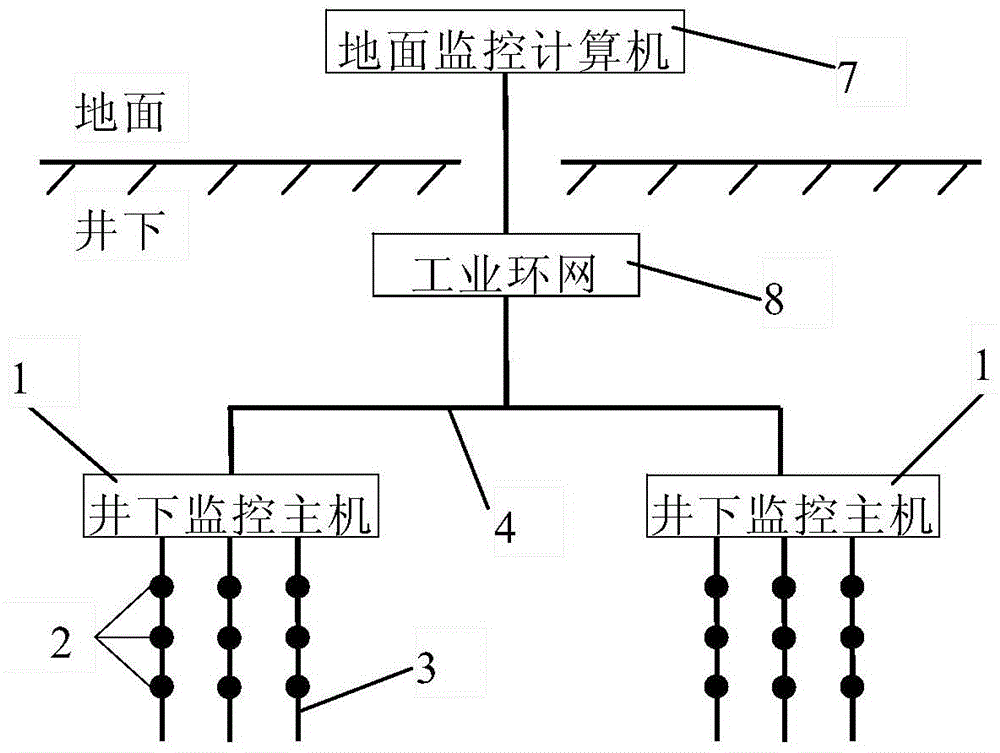

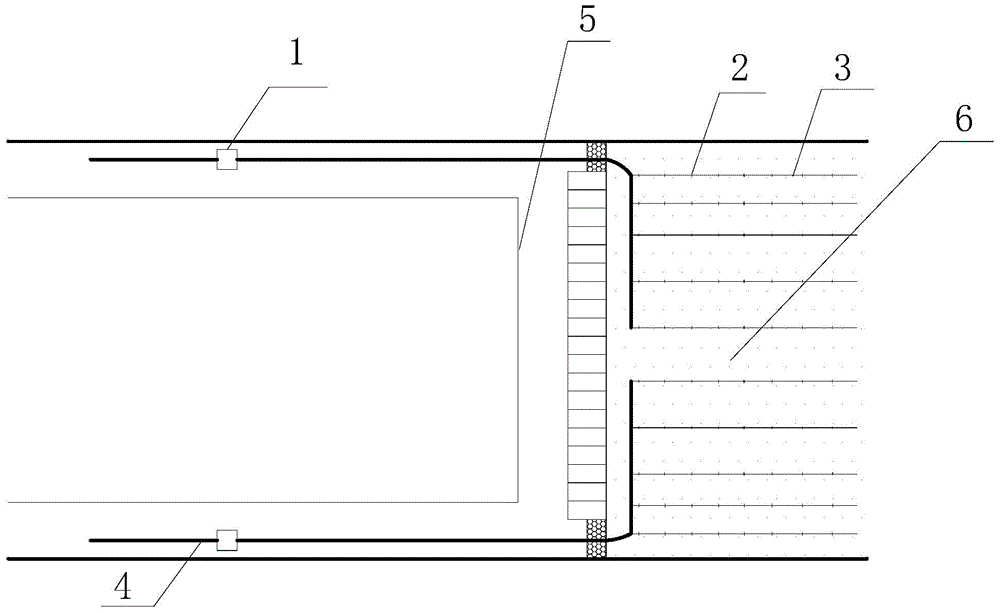

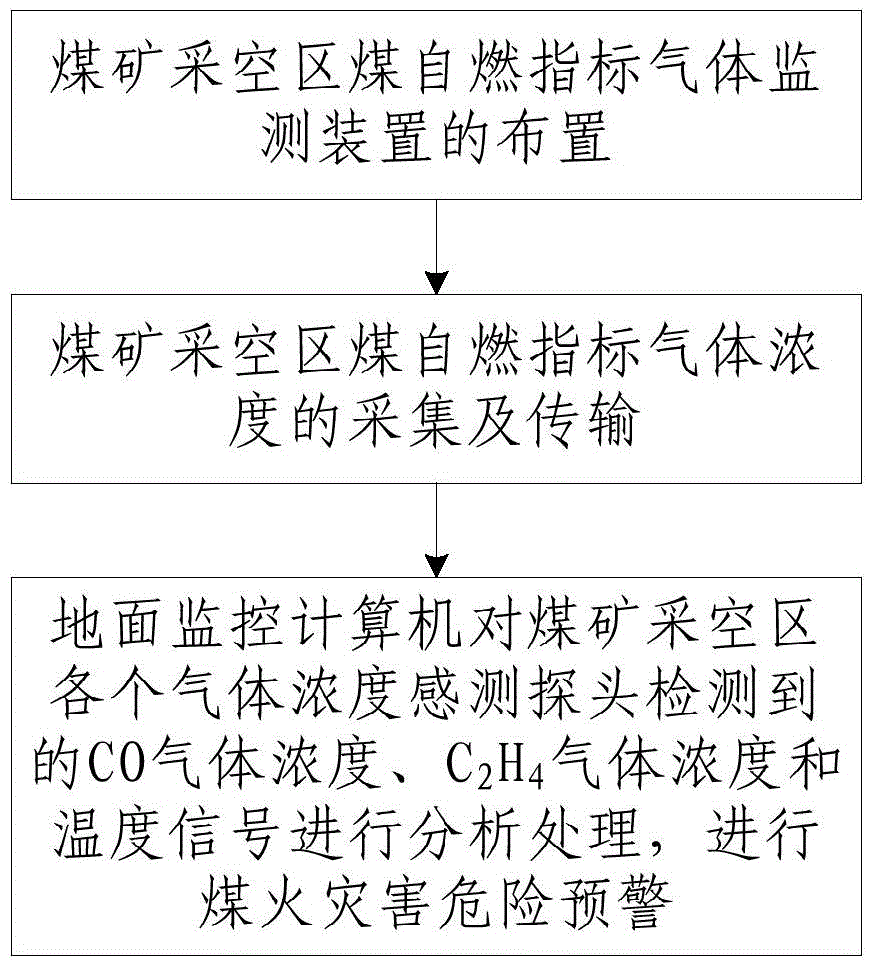

[0044] Such as figure 1 , figure 2 and image 3 As shown, the goaf coal spontaneous combustion risk degree discrimination and early warning method based on index gas of the present invention comprises the following steps:

[0045] Step 1. Arrangement of coal spontaneous combustion indicator gas monitoring devices in the goaf of the coal mine: arrange multiple gas monitoring devices for detecting CO gas concentration, C 2 h 4 The gas concentration and temperature sensing probe 2 of gas concentration and temperature defines the position where the gas concentration and temperature sensing probe 2 is arranged as a monitoring point, and connects a plurality of gas concentration and temperature sensing probes 2 to the downhole monitoring host 1, The gas concentration and temperature sensing probe 2 is integrated with a CO gas sensor, C 2 h 4 A gas sensor and a temperature sensor, the downhole monitoring host 1 is connected to the industrial ring network 8 through the communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com