Hydraulic air pressure test device

A technology of air pressure test and water pressure test, applied in the field of tightness inspection, can solve the problems of increased test cost, long time, large manpower and material cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0020] The core of the present invention is to convert the air pressure test into a water pressure test through the rubber air bag. Since the rubber airbag can deform freely after being pressurized, the pressure inside and outside the airbag is always the same. By measuring the air pressure in the airbag in real time, it can ensure that the test achieves the same effect as the conventional air pressure test.

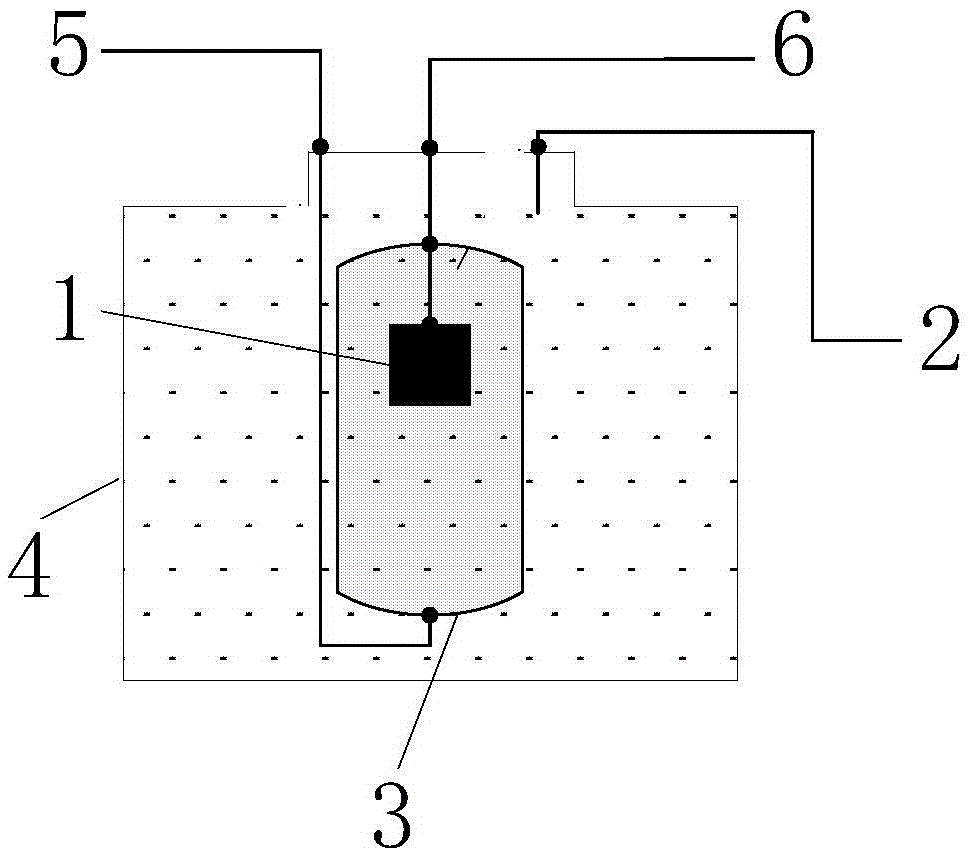

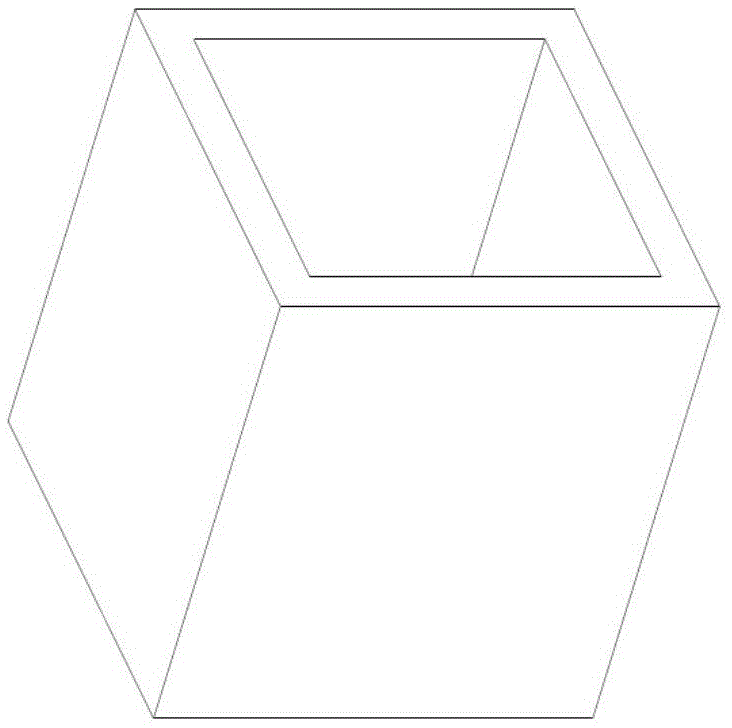

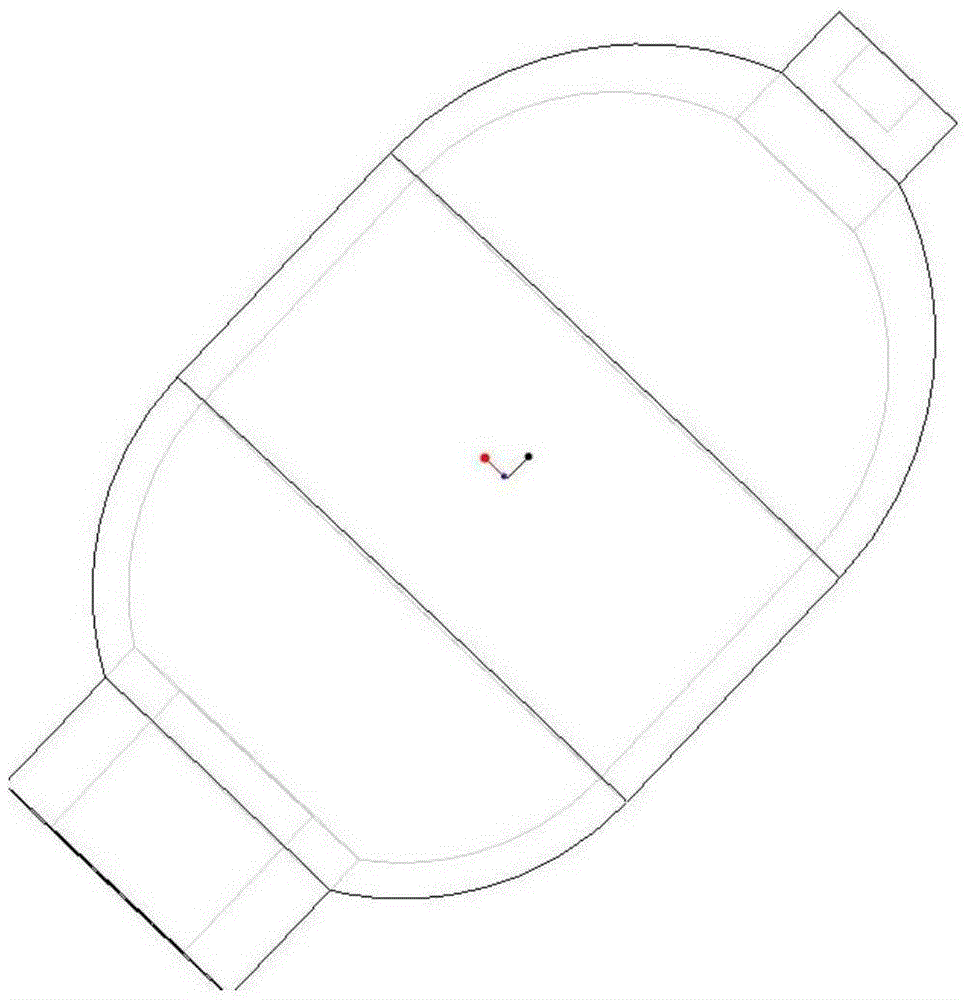

[0021] Such as figure 1 As shown, the hydraulic pressure test device of the present invention includes: a structural member to be inspected 1, a hydraulic device 2, a rubber air bag 3, a hydraulic test container 4, a high-pressure helium cylinder 5, and a helium detection device 6.

[0022] The structure to be inspected 1, the rubber airbag 3, and the water pressure test container 4 are all airtight containers; the rubber airbag 3 has two openings a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com