Method for preparing fractured rock mass samples with filler

A cracked rock mass and fissure technology, applied in the field of rock mass sample preparation, can solve problems such as crack failure, rock mass failure, inflexibility, etc., achieve good dry shrinkage and crack resistance, protect the crack structure, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

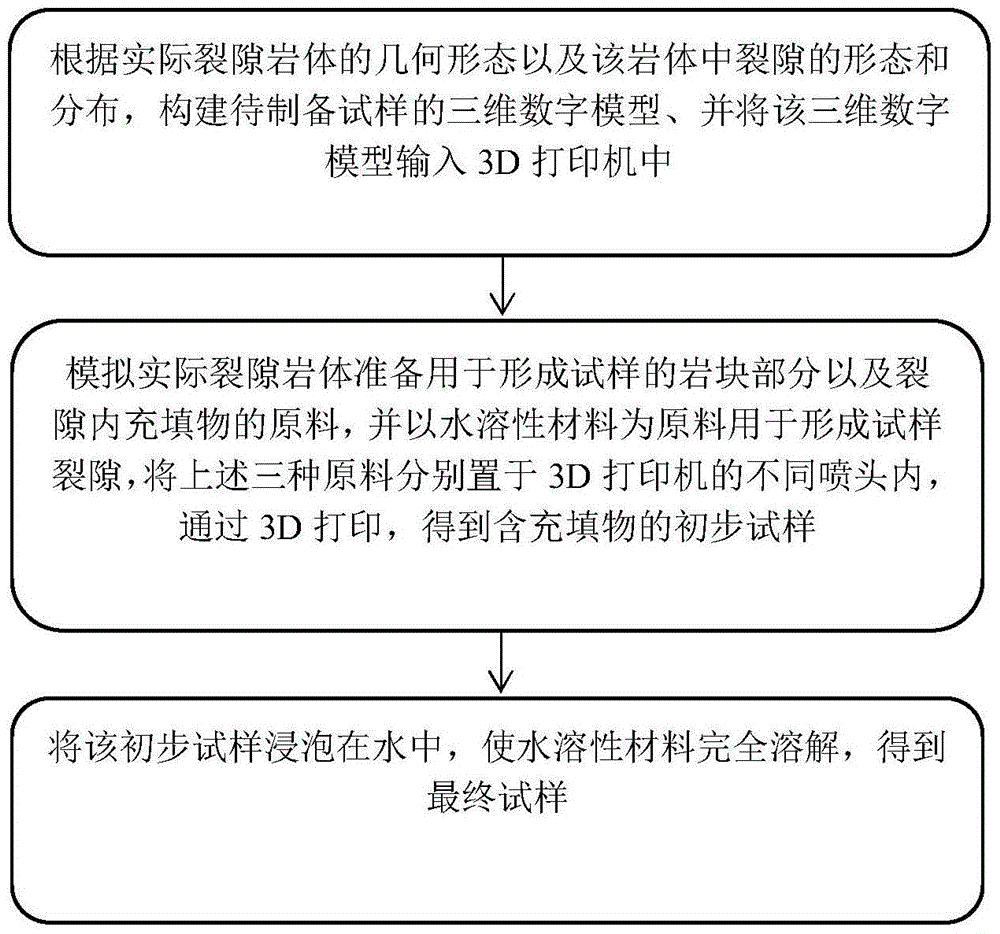

[0023] Such as figure 1 , The method for preparing a rock mass sample containing filled fractures of the present invention includes the following steps:

[0024] (1) Construct a three-dimensional digital model of the sample to be prepared according to the geometry of the actual fractured rock mass and the shape and distribution of the fractures in the rock mass, and input the three-dimensional digital model into a 3D printer;

[0025] For example, the 3D digital model of the actual fractured rock mass can be constructed by using SolidWorks software. When constructing the 3D digital model of the actual fractured rock mass, the model is generally a column of Φ50mm×100mm, and different sizes can also be established according to the requirements of the experiment. The model; by making a three-dimensional digital model, the size, spatial shape, number and distribution of the cracks can be accurately controlled, and the obtained samples can completely simulate the structure and mechanical...

Embodiment

[0031] Prepare and simulate a rock mass sample containing filling fractures at the foundation of a large hydropower station dam. The foundation of this large hydropower station is composed of a rock mass with a fracture surface, which is called a dam foundation rock mass.

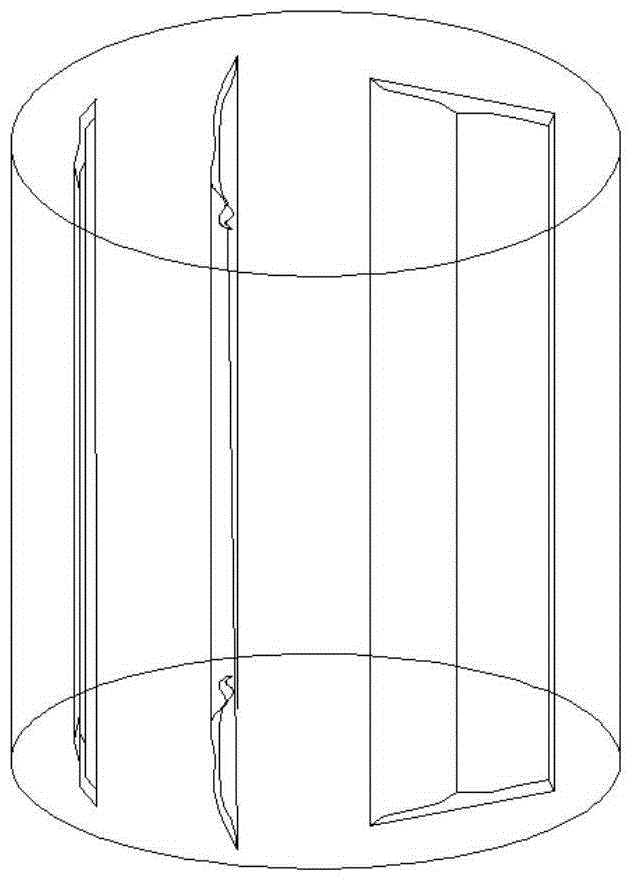

[0032] (1) Determine the length and width, spatial distribution and number of the cracks in the dam foundation rock mass through the description, measurement and analysis of the cracks in the rock mass of the dam, and determine the geometric dimensions of the sample to be prepared, the length and width of the cracks, and the length and width of the cracks in accordance with similar relationships. The distribution characteristics of the cracks such as spatial distribution and number; use computer-aided design software (SolidWorks) to construct a three-dimensional digital model of the sample to be prepared, the model is a cylinder of Φ50mm×100mm, such as figure 2 ;

[0033] (2) Prepare raw materials: simulate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com