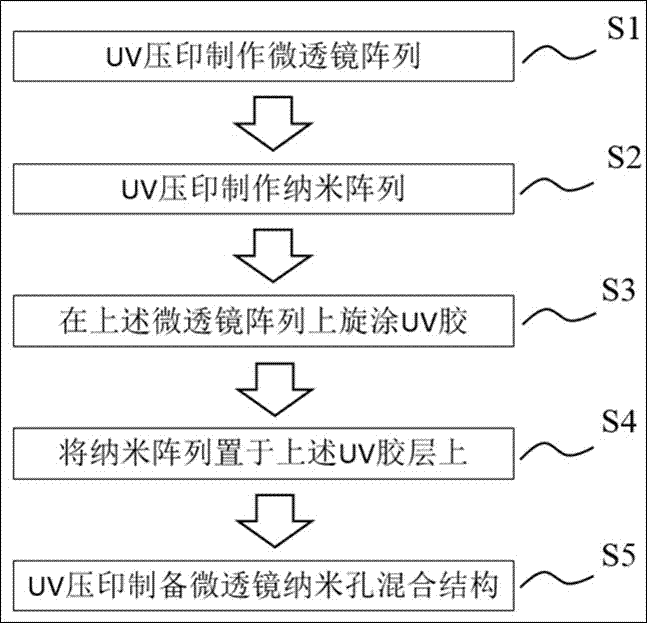

Preparation method of a microlens nanohole hybrid array structure

A technology of microlens array and hybrid structure, applied in the directions of lenses, instruments, optics, etc., can solve the problems of insurmountable surface mechanical properties, incompatibility, and high manufacturing costs, and achieve the effects of flexible and diverse methods, saving time, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. However, these embodiments do not limit the present invention, and the structural, method or functional changes made by those skilled in the art according to these specific embodiments without creative work shall be included in the protection scope of the present invention .

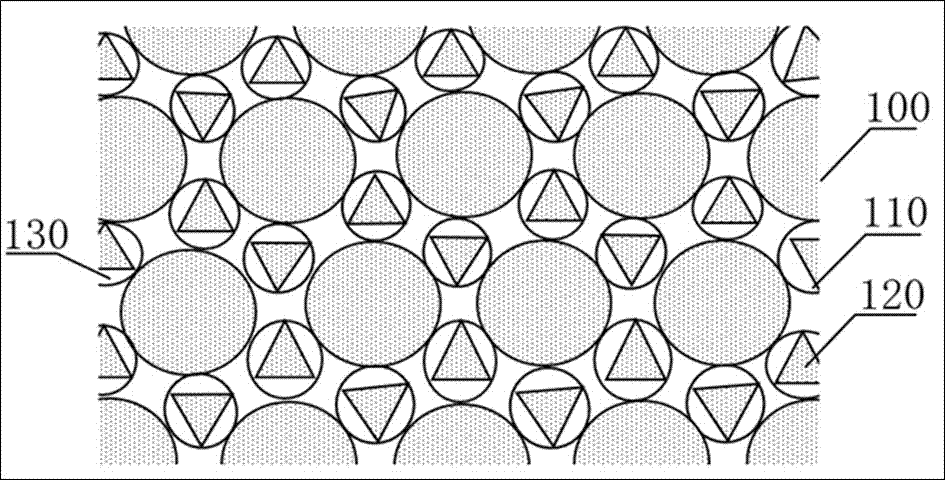

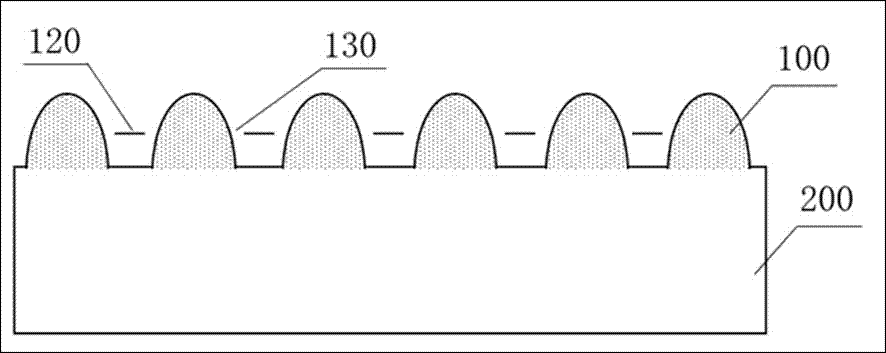

[0062] The invention discloses a preparation method of a microlens nanohole mixed structure. see figure 1 , figure 2 As shown, the structure includes materials made of UV-curable adhesive: microlens array 100, micron hole array 110 nested between the microlens arrays, micron triangular array 120 embedded in the micron hole array, micron hole array The nano-hole array 130 and the base 200 with optional materials are formed with the spaced regions embedded with micro-triangles.

[0063] The structure of each part in the present invention will be described in detail bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com