Photosensitive dry film with stable storage and preparation method of photosensitive dry film

A photosensitive dry film and dry film technology, applied in the direction of photographic platemaking process coating equipment, etc., can solve the problems of reducing production efficiency, reducing photopolymerization speed, increasing development time, etc., to block oxygen and water vapor damage, prevent cold flow, The effect of suppressing edge flow glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

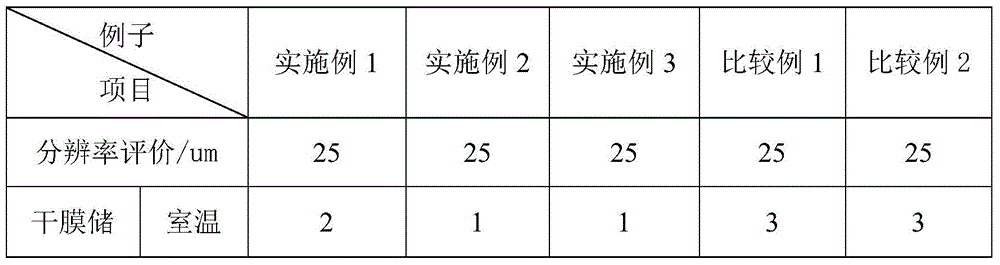

Examples

Embodiment 1-3

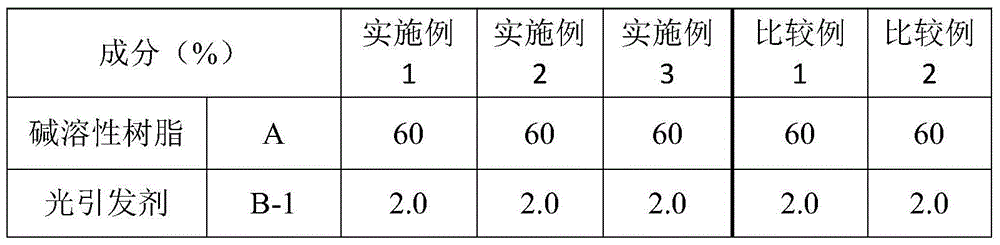

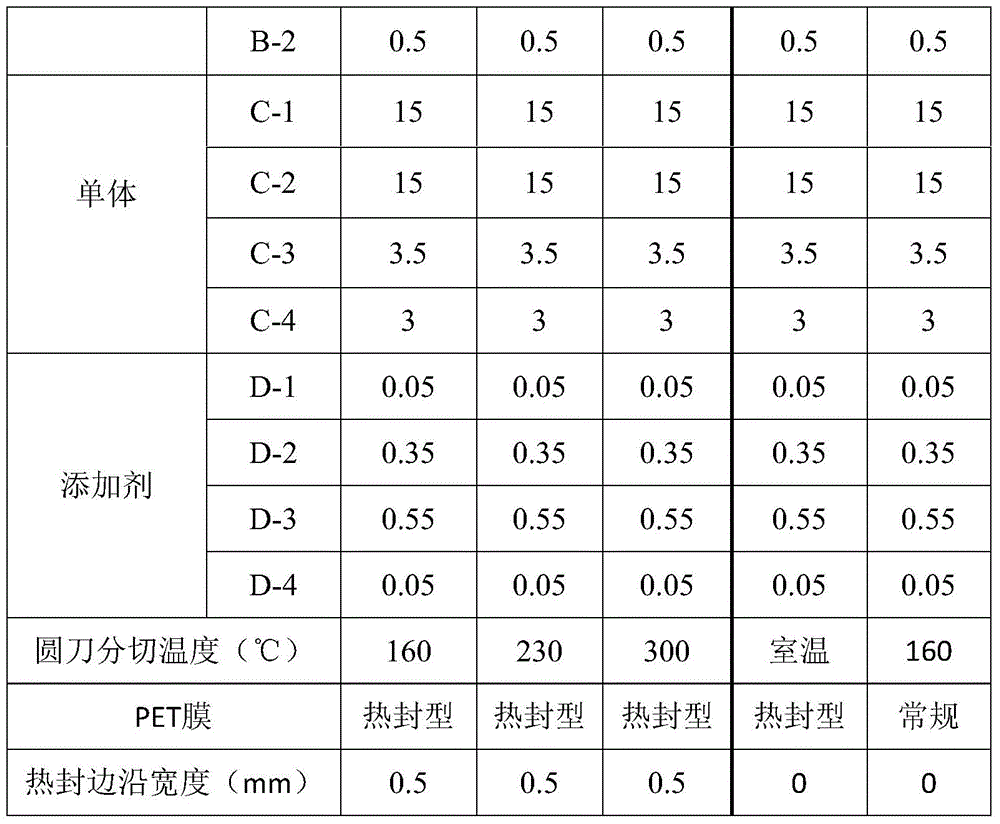

[0029] (embodiment 1-3, comparative example 1-2)

[0030] According to the formula in Table 1 below, the components were mixed in proportion, 60 parts by weight of acetone was added, and then fully stirred until completely dissolved to form a dry film solution with a solid content of 40%. On the production line, it is evenly coated on the surface of the PET film (15um thick) as a supporting film, and the solution is dried through a drying tunnel at a temperature of about 70°C to form a dry film resist layer with a thickness of 26um. Appears green. Then, a polyethylene film as a protective layer was pasted on its surface, with a thickness of 20um, so that a photosensitive dry film master roll with a three-layer structure was obtained. It was rolled up on a 6-inch roll with a length of 3000m and a width of 1260mm. Finally, according to the cutting temperature in Table 1, the photosensitive dry film master roll was cut to obtain the final dry film product with a length of 200m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com