Composite nano gold-platinum material, preparation method thereof and an application of composite nano gold-platinum material in direct methanol fuel cell anode catalyst

A composite material, platinum nanotechnology, applied in fuel cells, battery electrodes, nanotechnology, etc., can solve the problems of difficult to control product particle size and distribution, uneven Pt nanoparticles, unstable current and voltage, etc., to achieve anti-poisoning. The effect of improving ability, improving surface catalytic activity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

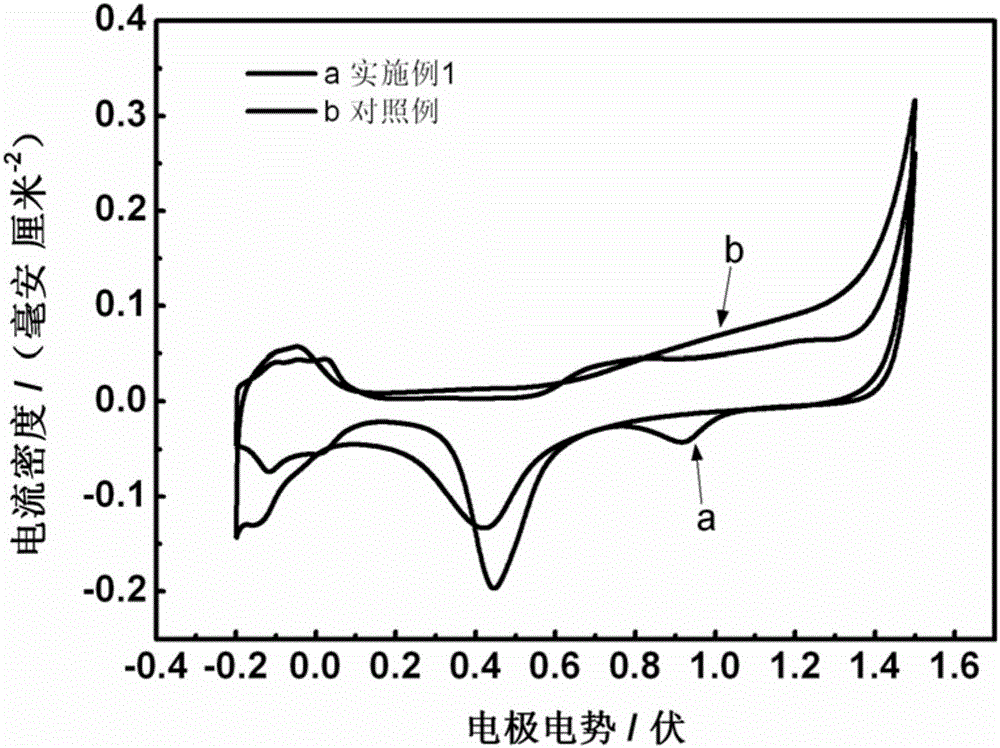

Embodiment 1

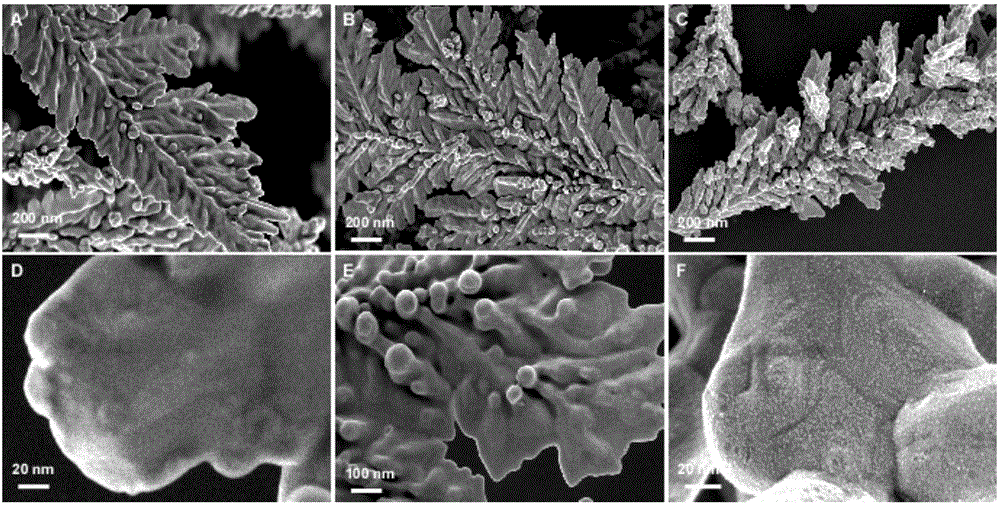

[0034] A gold-platinum nanocomposite material, in which the nanogold is dendritic, spherical platinum particles are decorated on the surface of the nanogold, the molar ratio of gold to platinum is 16:(4~5), and the size of the nanogold is 0.1~7 Micron, the size of platinum particles is 1.5-4 nanometers.

[0035] The preparation method of the above-mentioned gold-platinum nanocomposite material comprises the following process:

[0036] (1) Disperse 0.8mL of chloroauric acid with a concentration of 0.1mol / L in 7.2mL of potassium chloride solution with a concentration of 0.1mol / L to form a fresh yellow solution A, and ultrasonicate the solution A for 2 Minutes to make it fully mixed; 1mL of potassium chloroplatinite with a concentration of 0.02mol / L was dissolved in 18ml of ultrapure water to prepare solution B; 0.1mol / L of ascorbic acid was dissolved in 1ml of ultrapure water to prepare Solution C;

[0037] (2) The pretreated glassy carbon electrode was used as the working ele...

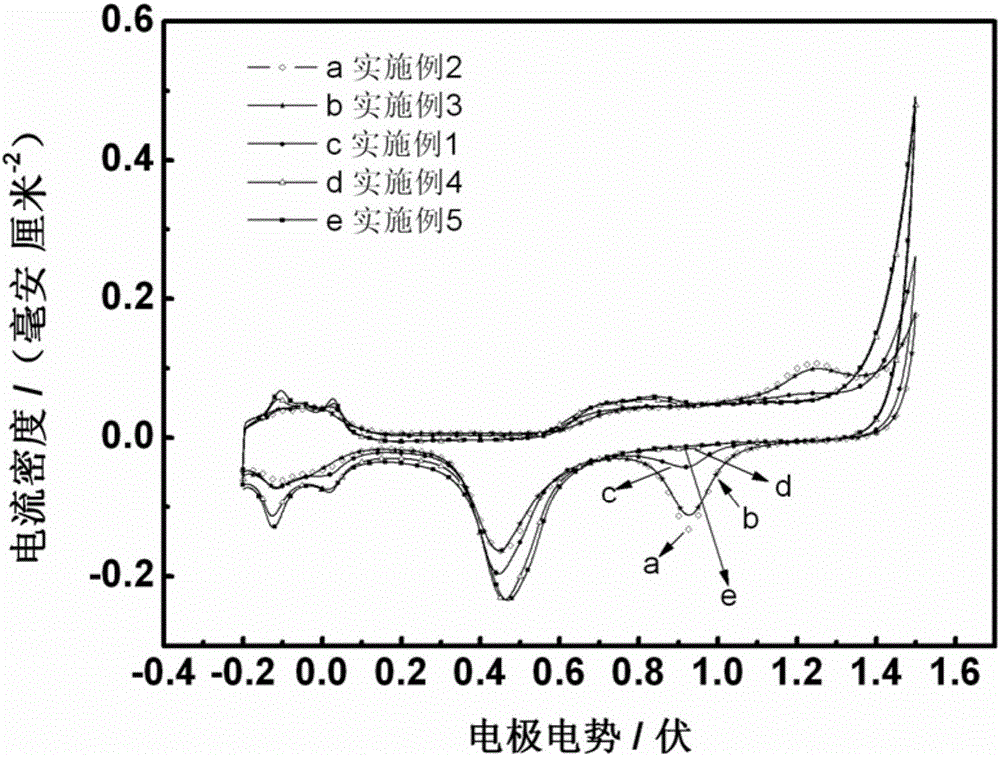

Embodiment 2

[0041] This example is the same as Example 1 except for the following features: insert the obtained nano-gold modified glassy carbon electrode into a solution of potassium chloroplatinite containing ascorbic acid, and deposit for 5 minutes.

Embodiment 3

[0043] This example is the same as Example 1 except for the following features: insert the obtained gold-modified glassy carbon electrode into a solution of potassium chloroplatinite containing ascorbic acid, and deposit for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com