A photocatalyst for highly selective oxidation of alcohols to aldehydes and its preparation and application

A photocatalyst and high-selectivity technology, applied in the field of photocatalyst and nano-photocatalyst, can solve the problems of unsatisfactory industrial application, low photocatalytic efficiency and product selectivity, and achieve high catalytic efficiency and product selectivity. Preparation method Ease of handling and improvement of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

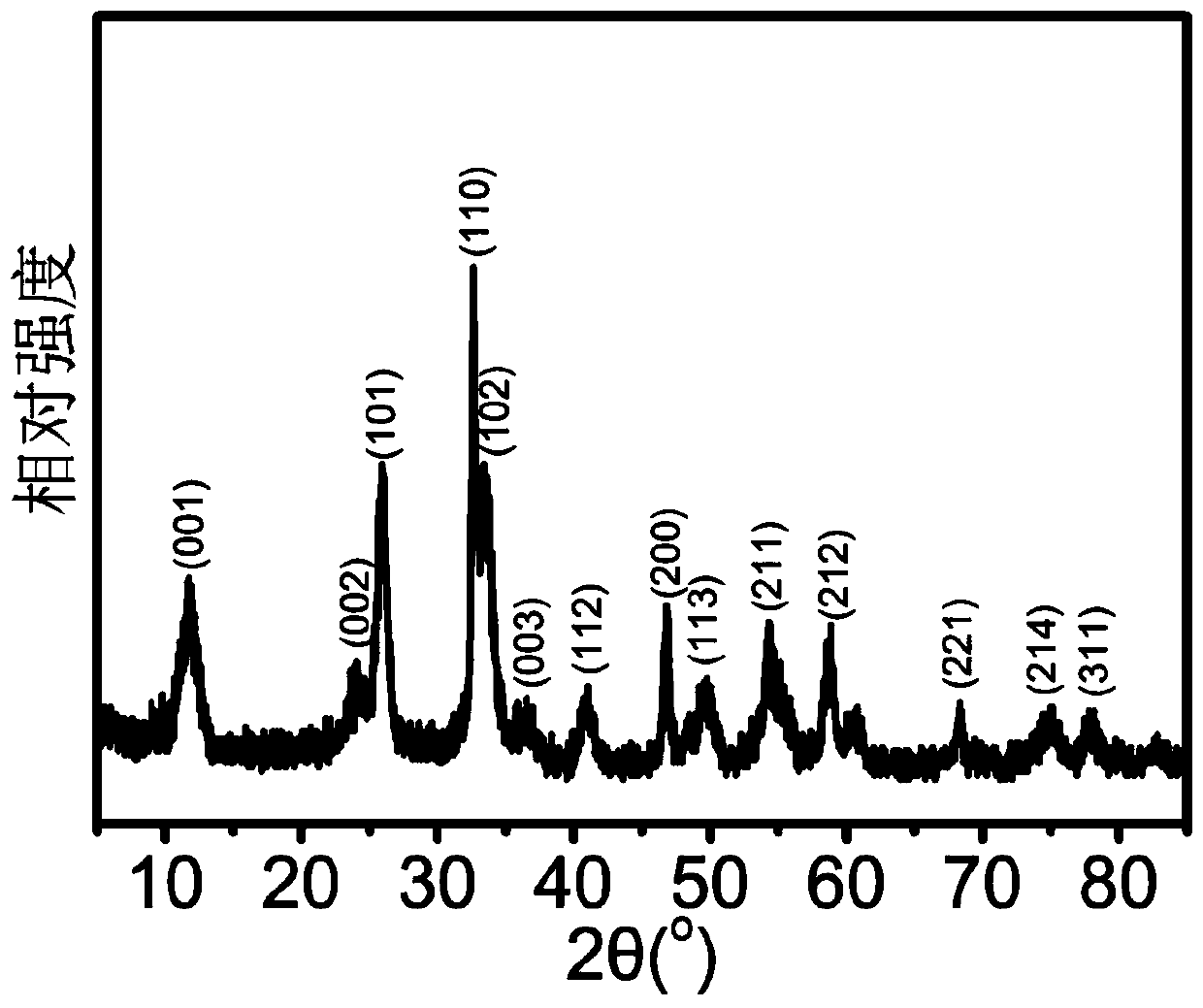

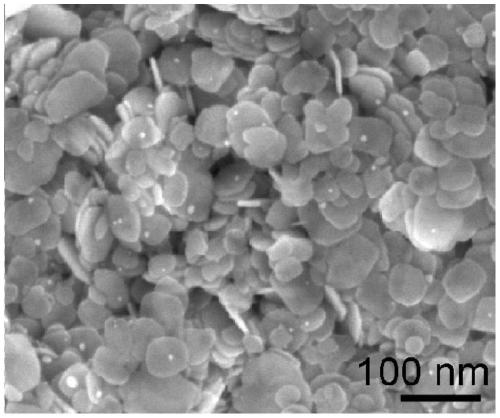

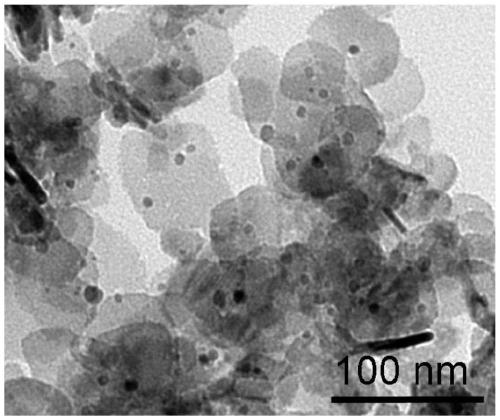

[0037] Preparation of BiOCl ultrathin nanosheets supported nano-Pd photocatalyst (Pd-BiOCl):

[0038] a. Dissolve 0.6mmol mannitol and 0.4g polyvinylpyrrolidone (PVP, K-30) in 60mL distilled water, stir to dissolve;

[0039] b. Dissolve 2.0 mmol of bismuth nitrate pentahydrate and sodium chloride in 10 mL of ethylene glycol, respectively, and ultrasonically form solutions at room temperature;

[0040] c. Add the solution prepared in step b to the solution in step a successively (add the solution containing bismuth nitrate pentahydrate first, then add the solution containing sodium chloride after mixing), transfer to a volume of 50mL after mixing In a hydrothermal reaction kettle, seal it, keep it warm at 160°C for 8 hours, cool to room temperature after the reaction, and centrifuge the generated precipitate, wash with distilled water and dry to obtain BiOCl ultrathin nanosheets;

[0041] d. Weigh 10 mg of the BiOCl ultrathin nanosheets obtained in step c and ultrasonically di...

Embodiment 2

[0045] Photocatalytic Selective Oxidation of Benzyl Alcohol to Benzaldehyde

[0046] a. Weigh 1 mg of Pd-BiOCl photocatalyst and ultrasonically disperse it in 2 mL of acetonitrile to form a suspension;

[0047] b. Add 50 μmol of benzyl alcohol to the suspension in step a, and stir evenly;

[0048] c. Transfer the mixed solution obtained in step b to a quartz tube, and irradiate with a xenon lamp with an optical power density of 158mW / cm 2 ;

[0049] d. The reaction solution in step c is centrifuged to take the supernatant, which is detected and analyzed by gas chromatography.

[0050] As can be seen from Table 1, along with the prolongation of illumination time, the productive rate of benzaldehyde produced by photocatalytic selective oxidation of benzyl alcohol is getting higher and higher, after reacting for 8 hours, conversion rate is close to 100%; While conversion rate improves constantly, The product selectivity to form benzaldehyde is always above 90%.

Embodiment 3

[0052] Photocatalytic Selective Oxidation of p-Toluene Alcohol to p-Tolualdehyde

[0053] a. Weigh 1 mg of Pd-BiOCl photocatalyst and ultrasonically disperse it in 2 mL of acetonitrile to form a suspension;

[0054] b. Add 50 μmol p-methylbenzyl alcohol to the suspension in step a, and stir evenly;

[0055] c. Transfer the mixed solution obtained in step b to a quartz tube, and irradiate with a xenon lamp with an optical power density of 158mW / cm 2 ;

[0056] d. The reaction solution in step c is centrifuged to take the supernatant, which is detected and analyzed by gas chromatography.

[0057] As can be seen from accompanying table 2, after 8 hours of illumination, the conversion rate of photocatalytic selective oxidation of p-methylbenzyl alcohol to generate p-tolualdehyde exceeds 80%, and the photocatalytic selective oxidation of p-methylbenzyl alcohol generates The product selectivity to p-tolualdehyde was 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com