A kind of preparation method of highly active platinum nanowire catalyst

A platinum nanowire and catalyst technology, applied in the field of preparation of high-activity platinum nanowire catalyst, can solve the problems of poor catalyst stability, high catalyst cost, complex process, etc., achieve catalytic activity and durability improvement, improve surface catalytic activity, The effect of reducing the chance of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

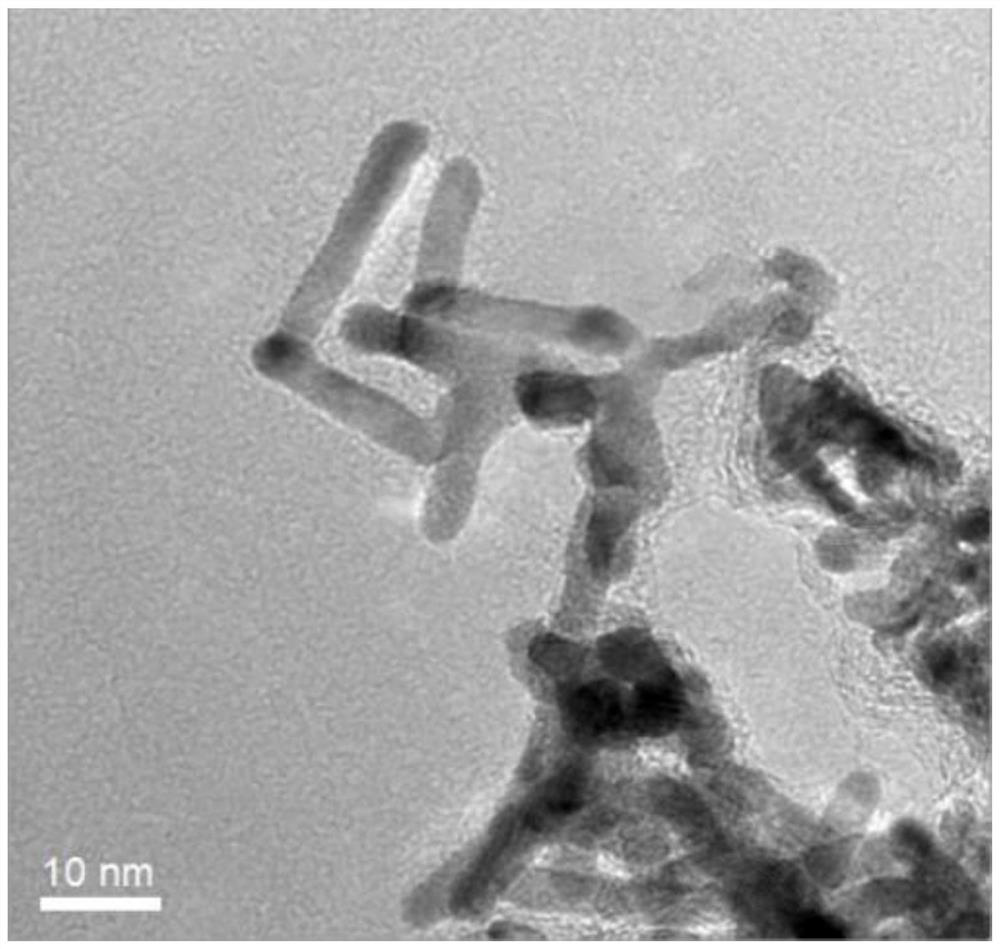

[0020] A kind of preparation method of highly active platinum nanowire catalyst, its steps are as follows,

[0021] S1. Weigh 51.781mg of chloroplatinic acid, 11.22mg of potassium hydroxide and 13mg of EC600 carbon black, add 2mL of ultrapure water to dissolve, place them in an ultrasonic device with a power of 30W for 1h, and obtain a mixed solution;

[0022] S2. Dry the mixed solution obtained in S1 at 80° C. for 1.5 h in a vacuum drying oven;

[0023] S3. Put the black solid mixture obtained in S2 in a tube furnace, first pass nitrogen gas to discharge the air, and then pass in reducing gas hydrogen for reduction. The reduction temperature is 250 ° C and the time is 30 minutes, and the highly active platinum nanometer can be obtained. line catalyst.

Embodiment 2

[0025] A kind of preparation method of highly active platinum nanowire catalyst, its steps are as follows,

[0026] S1. Weigh 51.781mg of chloroplatinic acid, 11.22mg of potassium hydroxide and 13mg of Lishui 10nm treated carbon black, dissolve them in 2mL of ultrapure water, put them in an ultrasonic device with a power of 30W for 1h, and obtain a mixed solution ;

[0027] S2. Dry the mixed solution obtained in S1 at 80° C. for 1.5 h in a vacuum drying oven;

[0028] S3. Put the black solid mixture obtained in S2 in a tube furnace, first pass nitrogen gas to discharge the air, and then pass in reducing gas hydrogen for reduction. The reduction temperature is 250 ° C and the time is 30 min. Highly active platinum nanowires can be obtained. catalyst.

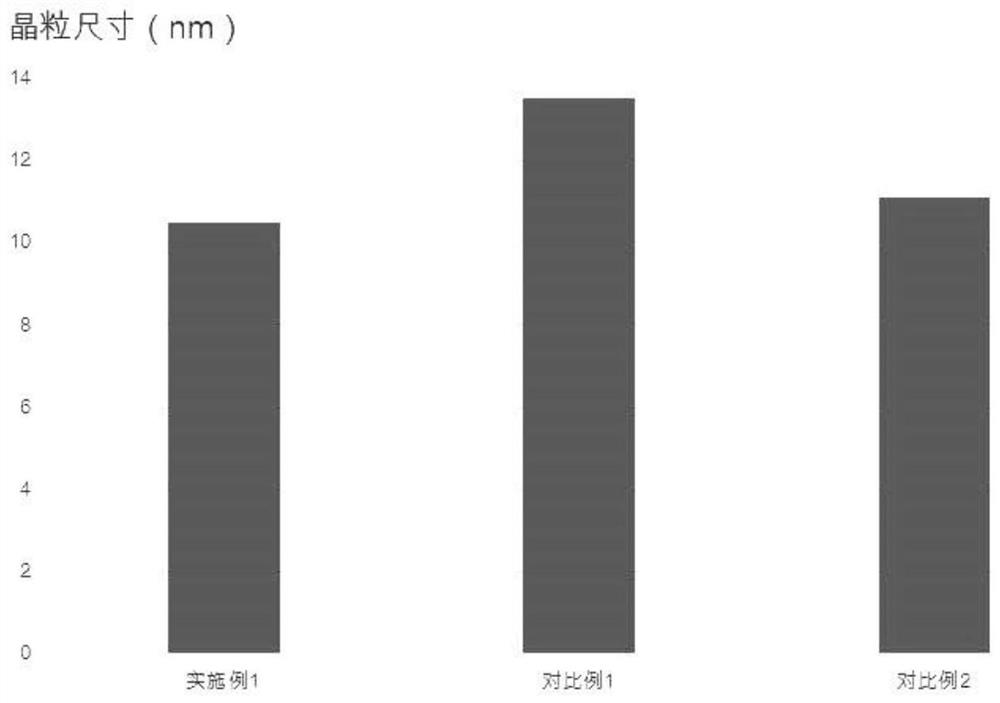

[0029] The comparison groups are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com