Preparation method of clonazepam molecularly imprinted stirring rod coating

A technology of molecular imprinting and clonazepam, which is applied in the field of analysis and detection, can solve the problems of time-consuming and cumbersome coating preparation, and achieve the effects of improving the effective utilization rate, enhancing the recognition and adsorption capacity, and optimizing the test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

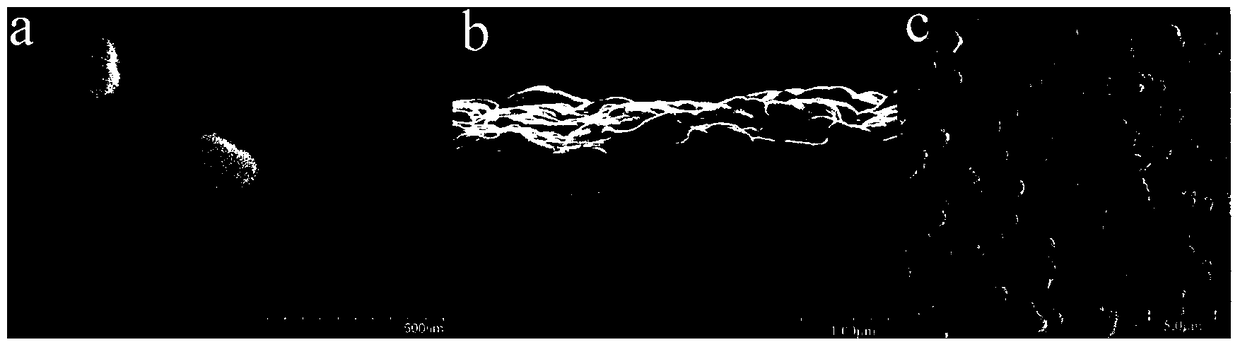

[0051] (1) Preparation and activation of a magnetic stirring rod: Put a thin magnetic iron rod into a glass tube, sinter and seal both ends to make a magnetic stirring rod; Wash with water until neutral and activate; place the activated stirring bar in a silane coupling agent for silanization reaction, wash with methanol, and blow dry with nitrogen; the alkali solution is 1mol / L NaOH solution; the acid solution is 0.5mol / L L of hydrochloric acid solution; the soaking time is 18h and 2h respectively, and the silane coupling agent is a γ-methacryloxypropyltrimethoxysilane acetone solution with a mass concentration of 20%; the diameter of the magnetic stirring rod is 0.3cm, and the length It is 1.1cm. The silanization time is 1h.

[0052] (2) Magnetic nanoparticles modified with terminal diaminobenzyl carboxyl groups (gf-Fe 3 o 4 ) preparation: 1g Fe 3 o 4 @SiO 2 Disperse nanoparticles in toluene, add 20mL silane coupling agent, react at 110°C for 25h under nitrogen protect...

Embodiment 2

[0056] (1) Preparation and activation of a magnetic stirring rod: Put a thin magnetic iron rod into a glass tube, sinter and seal both ends to make a magnetic stirring rod; Wash with water until neutral and activate; place the activated stirring bar in a silane coupling agent for silanization reaction, wash with methanol, and blow dry with nitrogen; the alkali solution is 1mol / L NaOH solution; the acid solution is 0.5mol / L L of hydrochloric acid solution; the soaking time is 18h and 2h respectively, and the silane coupling agent that reacts with the stirring bar is a γ-methacryloxypropyltrimethoxysilane acetone solution with a mass concentration of 20%; the diameter of the magnetic stirring bar It is 0.3cm and the length is 1.1cm. The silanization reaction time is 2h.

[0057] (2) Magnetic nanoparticles modified with terminal diaminobenzyl carboxyl groups (gf-Fe 3 o 4 ) preparation: 1g Fe 3 o 4 @SiO 2 Disperse nanoparticles in toluene, add 20mL silane coupling agent, rea...

Embodiment 3

[0061] (1) Preparation and activation of a magnetic stirring rod: Put a thin magnetic iron rod into a glass tube, sinter and seal both ends to make a magnetic stirring rod; Wash with water until neutral and activate; place the activated stirring bar in a silane coupling agent for silanization reaction, wash with methanol, and blow dry with nitrogen; the alkali solution is 1mol / L NaOH solution; the acid solution is 0.5mol / L L of hydrochloric acid solution; the soaking time is 18h and 2h respectively, and the silane coupling agent that reacts with the stirring bar is a γ-methacryloxypropyltrimethoxysilane acetone solution with a mass concentration of 20%; the diameter of the magnetic stirring bar It is 0.3cm and the length is 1.1cm. The silylation reaction time is 3h.

[0062] (2) Magnetic nanoparticles modified with terminal diaminobenzyl carboxyl groups (gf-Fe 3 o 4 ) preparation: 1g Fe 3 o 4 @SiO 2 Disperse nanoparticles in toluene, add 20mL silane coupling agent, react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com