A processing method of a steel split ring and a device for realizing the method

A processing method and split ring technology, which is applied in the processing field of split rings, can solve the problems of complex processing methods, long production cycle, and high production cost, and achieve the effects of reducing the number of processing steps, shortening the production cycle, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

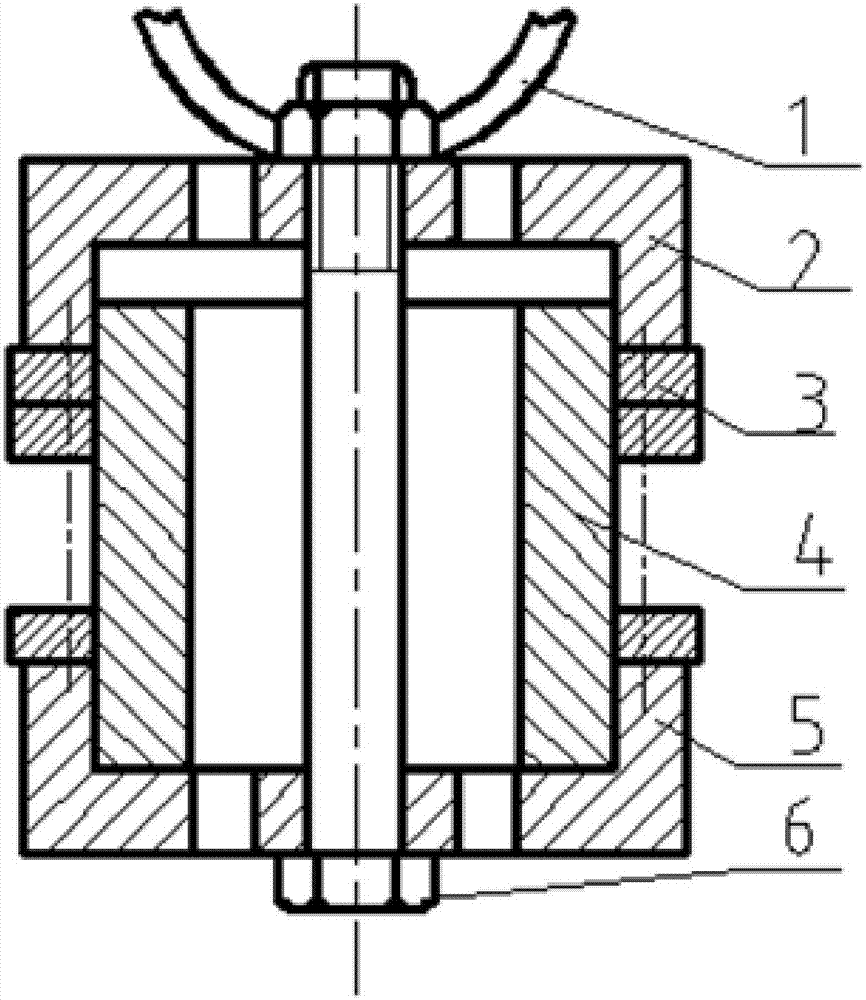

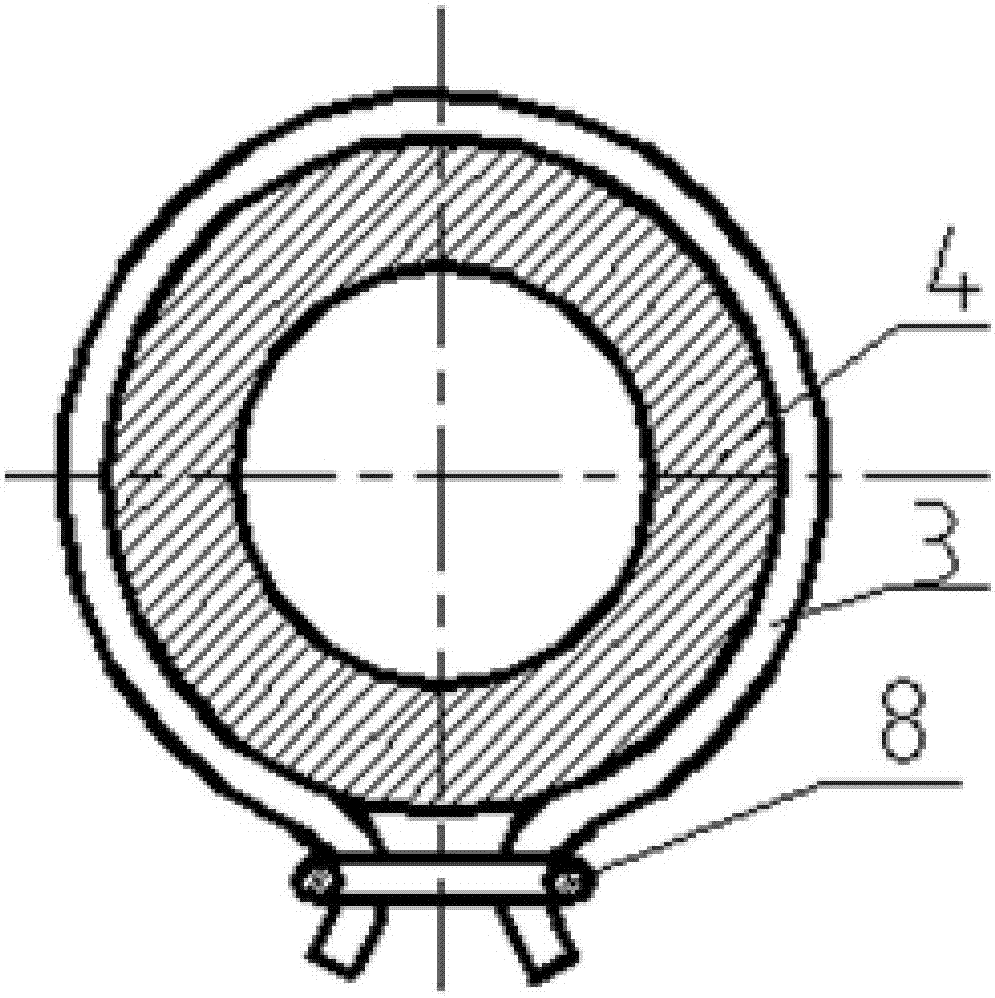

[0037] Specific implementation mode one: combine figure 1 and 2 Describe this embodiment, the processing method of a kind of steel split ring described in this embodiment, the concrete procedure of this method is:

[0038] A processing method for a steel split ring, characterized in that the specific steps of the method are:

[0039] Process 1, roll forming:

[0040] Process 1.1. According to the method of densely coiled cylindrical helical spring, the profile is wound into a multi-turn ring with the same diameter as the split ring blank and close contact between the turns;

[0041] Step 1.2, cutting the multi-circle ring into a single-circle steel split ring blank 3;

[0042] Step 1.3, making two chucks from the two ends of the steel split ring blank 3;

[0043] Process 1.4, put the steel split ring blank 3 on the cylindrical tube 4, the steel split ring blank 3 is parallel to the cross section of the cylindrical tube 4; the iron wire tie 8 tightens the two chucks so that...

specific Embodiment approach 2

[0053] Specific implementation mode two: combination figure 1 and 2 Describe this embodiment, the processing method of a kind of steel split ring described in this embodiment, the concrete procedure of this method is:

[0054] Process 1, roll forming:

[0055] Process 1.1. According to the method of densely coiled cylindrical helical spring, the profile is wound into a multi-turn ring with the same diameter as the split ring blank and close contact between the turns;

[0056] Step 1.2, cutting the multi-circle ring into a single-circle steel split ring blank 3;

[0057] Step 1.3, making two chucks from the two ends of the steel split ring blank 3;

[0058] Process 1.4. Set the steel split ring blank 3 on the cylindrical tube 4, the steel split ring blank 3 is parallel to the cross section of the cylindrical tube 4; the iron wire tie 8 tightens the two chucks so that the steel The split ring blank 3 is in close contact with the cylinder 4;

[0059] Step 1.5. Insert the two...

specific Embodiment approach 3

[0067] Specific implementation mode three: combination figure 1 and 2 Describe this embodiment, this embodiment is a further limitation of the processing method of a steel split ring described in Embodiment 1 or 2, in this embodiment, the method for making two chucks described in process 1.3 is : The two ends of the steel split ring blank 3 are respectively bent toward the outer direction of the ring, so that the steel split ring blank 3 is in the shape of "Ω".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com