Lamp solder paste

A welding mud and lamp cap technology, applied in the directions of non-polymer adhesive additives, adhesive types, rosin adhesives, etc., can solve the problems of local uneven thickness, glass cracking, short service life, etc., and reduce cracking. Probability, beneficial to long-term use, and the effect of reducing heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

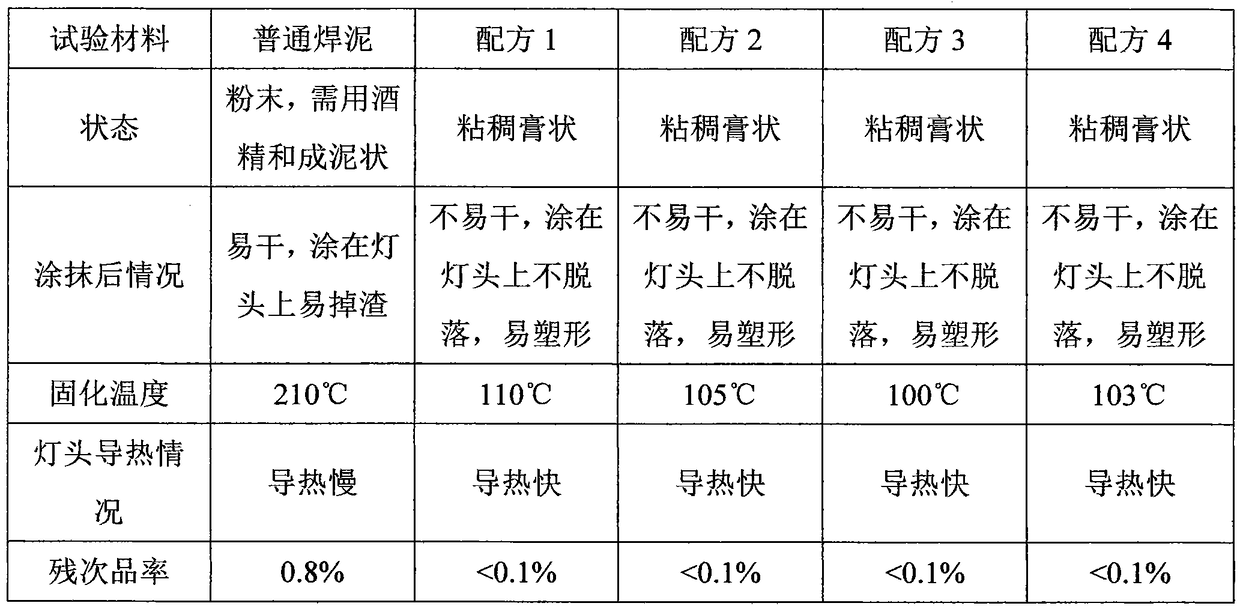

Embodiment 1

[0013] Embodiment 1 Lamp solder paste formula 1

[0014] 300 parts of rosin, 100 parts of shellac, 600 parts of 217 phenolic resin, 500 parts of ethanol, 100 parts of thermally conductive carbon fiber, 600 parts of zinc sulfide powder, 800 parts of barium sulfate powder, 1500 parts of calcium carbonate powder, and 400 parts of silicon-modified polyurethane.

Embodiment 2

[0015] Embodiment 2 Lamp cap welding paste formula 2

[0016] 400 parts of rosin, 200 parts of shellac, 800 parts of 217 phenolic resin, 800 parts of ethanol, 200 parts of thermally conductive carbon fiber, 800 parts of zinc sulfide powder, 1000 parts of barium sulfate powder, 2000 parts of calcium carbonate powder, and 500 parts of silicon-modified polyurethane.

Embodiment 3

[0017] Embodiment 3 Lamp cap welding paste formula 3

[0018] 350 parts of rosin, 150 parts of shellac, 700 parts of 217 phenolic resin, 600 parts of ethanol, 150 parts of thermally conductive carbon fiber, 700 parts of zinc sulfide powder, 900 parts of barium sulfate powder, 1800 parts of calcium carbonate powder, and 450 parts of silicon-modified polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com