Special oil for quick-frozen food and preparation method thereof

A technology for quick-frozen food and oil, which is applied in the production/processing and fermentation of edible oil/fat components, edible oil/fat, etc., can solve the problems of separation and purification of unfavorable products, destruction of immobilized enzyme structure, and reduction of repeated utilization rate, etc. Achieve the effect of not easy to be destroyed and reused, high catalytic efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh raw materials according to the following formula (weight): palm stearin and soybean oil weight ratio 7:3, 6:4, 5:5, soybean lecithin 0.2g, propylene glycol ester 0.2g, sorbitan fatty acid ester 0.2 g, 0.002 g of butyl hydroxyanisole, and 0.005 g of 2,6-di-tert-butyl-p-cresol.

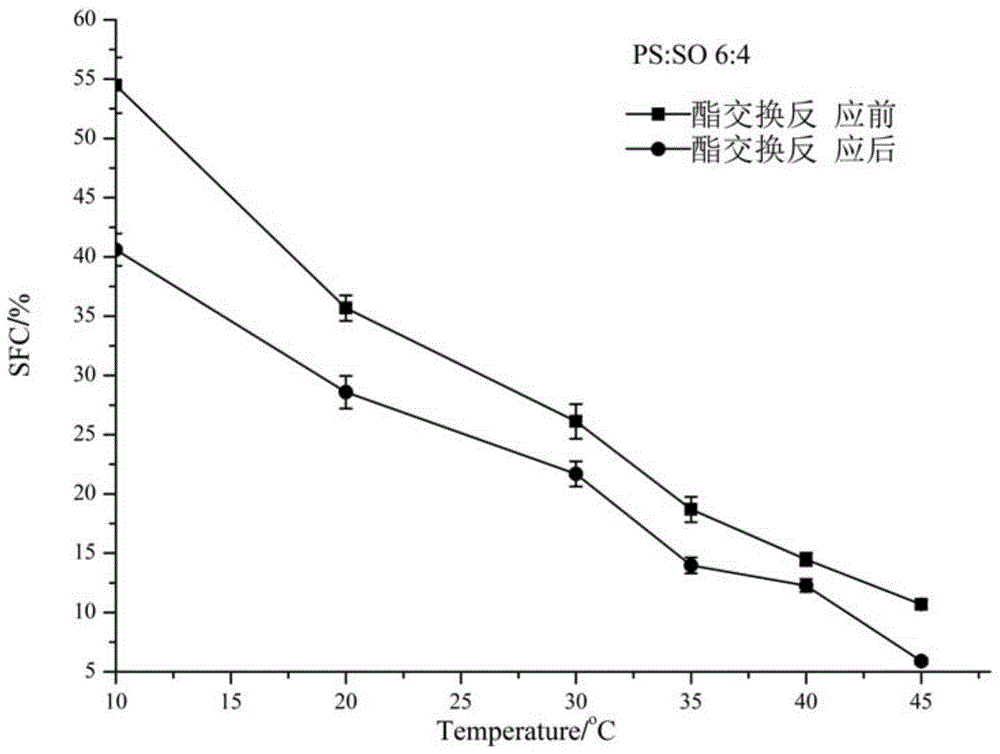

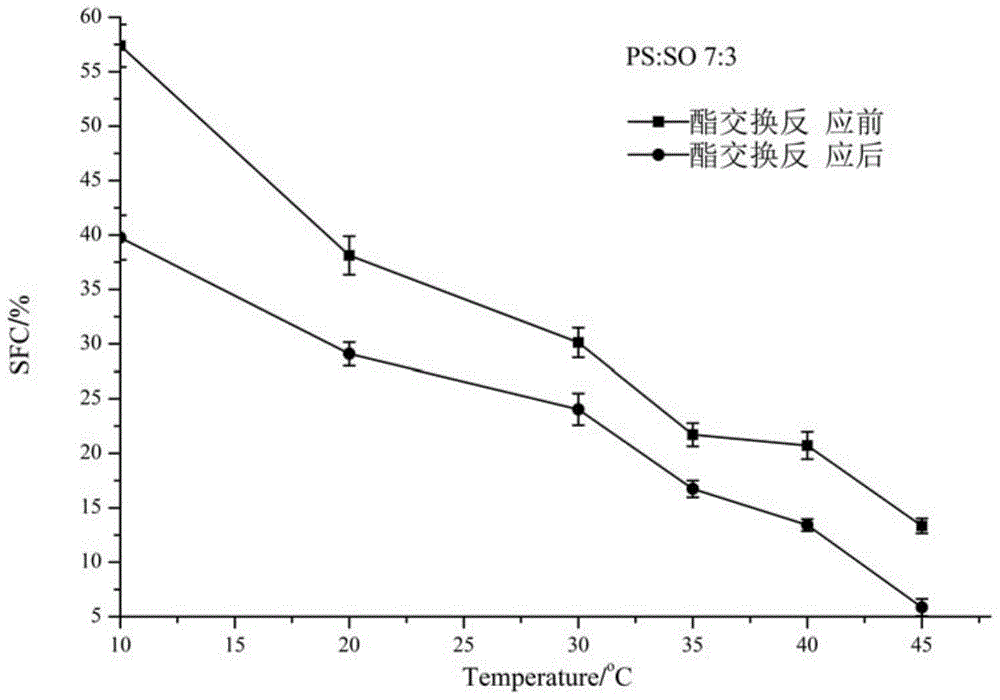

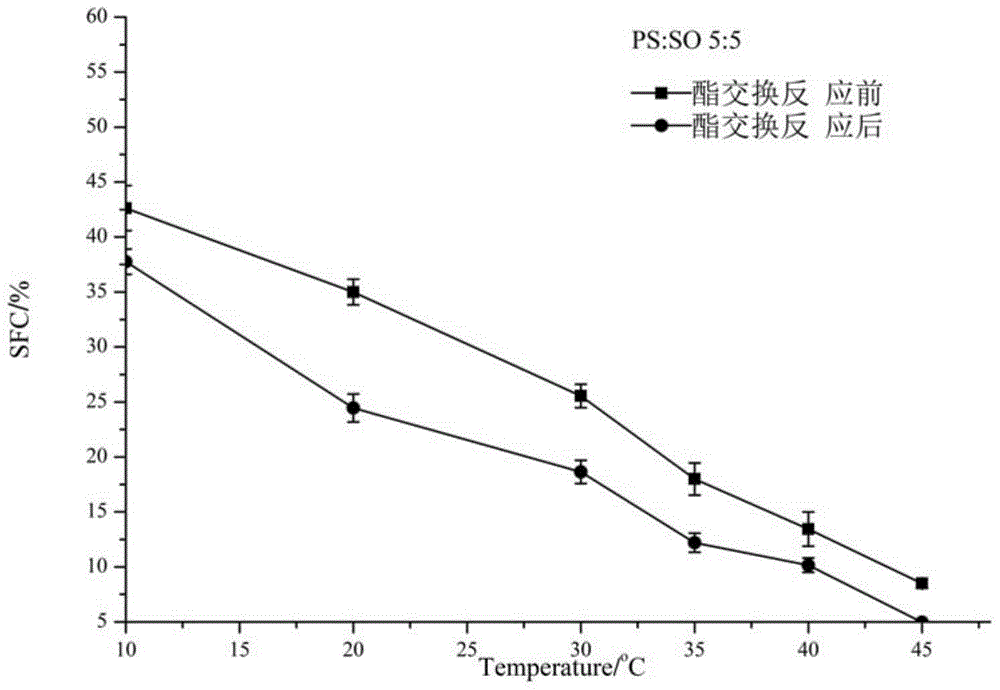

[0039] The preparation method of physical mixed oils: After heating, melting and mixing palm stearin and soybean oil with a weight ratio of 7:3, 6:4, and 5:5, measure the solid fat content of the three mixed oils, X-ray Atlas and polarizing microscope images. Special grease for quick-frozen food requires a wide range of plasticity at 20-35°C, a high content of β′ crystal form, and fine crystals of grease. but by Figure 1~3 It can be seen that the physically mixed oil before transesterification has a narrow plasticity range at 20-35°C, which is not conducive to oil processing; Figure 4~6 It can be seen that the high content of β crystal form in physically mixed oil will cause the oil pr...

Embodiment 2

[0041]Weigh the raw materials according to the following formula (weight): the weight ratio of palm stearin and soybean oil is 6:4, and the amount of immobilized lipase LipozymeTLIM is 1 / 2 of the height of the reaction column in the fluidized bed reactor (Φ12 × 350mm, with water circulation jacket). 2 / 3 (10g), soybean lecithin 0.2g, propylene glycol ester 0.2g, sorbitan fatty acid ester 0.2g, butylhydroxyanisole 0.002g, 2,6-di-tert-butyl-p-cresol 0.005g.

[0042] The preparation method of the transesterified oil: heat, melt and mix the palm stearin and soybean oil with a ratio of parts by weight of 6:4, then dehydrate and degas in vacuum at 90°C for 1 hour, cool to 60°C for later use, and transfer to a fluidized bed reactor ( Φ12×350mm, with a water circulation jacket), add 2 / 3 of the reaction column height immobilized lipase (10g), feed circulating water into the water circulation jacket, and use a constant flow pump to cool the raw material oil to 60°C with The flow rate of ...

Embodiment 3

[0047] Weigh raw materials according to the following formula: palm stearin and soybean oil weight ratio 7:3, immobilized lipase LipozymeTLIM 10g, soybean lecithin 0.2g, propylene glycol ester 0.2g, sorbitan fatty acid ester 0.2g, butylated hydroxyl Anisole 0.002g, 2,6-di-tert-butyl-p-cresol 0.003g.

[0048] The preparation method of transesterified oil: mix palm stearin and soybean oil with a weight ratio of 6:4, dehydrate and degas in vacuum at 90°C for 1 hour, cool to 60°C for later use, add to the reactor described in Example 2 10g of immobilized lipase TLIM, put circulating water into the reactor water circulation jacket, pump the cooled raw oil and fat from the bottom of the reactor into the reactor enzyme column at a flow rate of 0.4ml / min with a constant flow pump, and control the reaction The temperature was 60°C, and the transesterified oil was collected from the upper end of the reactor.

[0049] Preparation method of special oil for quick-frozen food Take 85g of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com