Hydraulic overload protection device and mechanical press with hydraulic overload protection device

An overload protection and press technology, applied in the direction of presses, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of poor working stability, long time required for the press to resume normal work, slow response to unloading action, etc. Improved accuracy and reliability, debugging and user-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

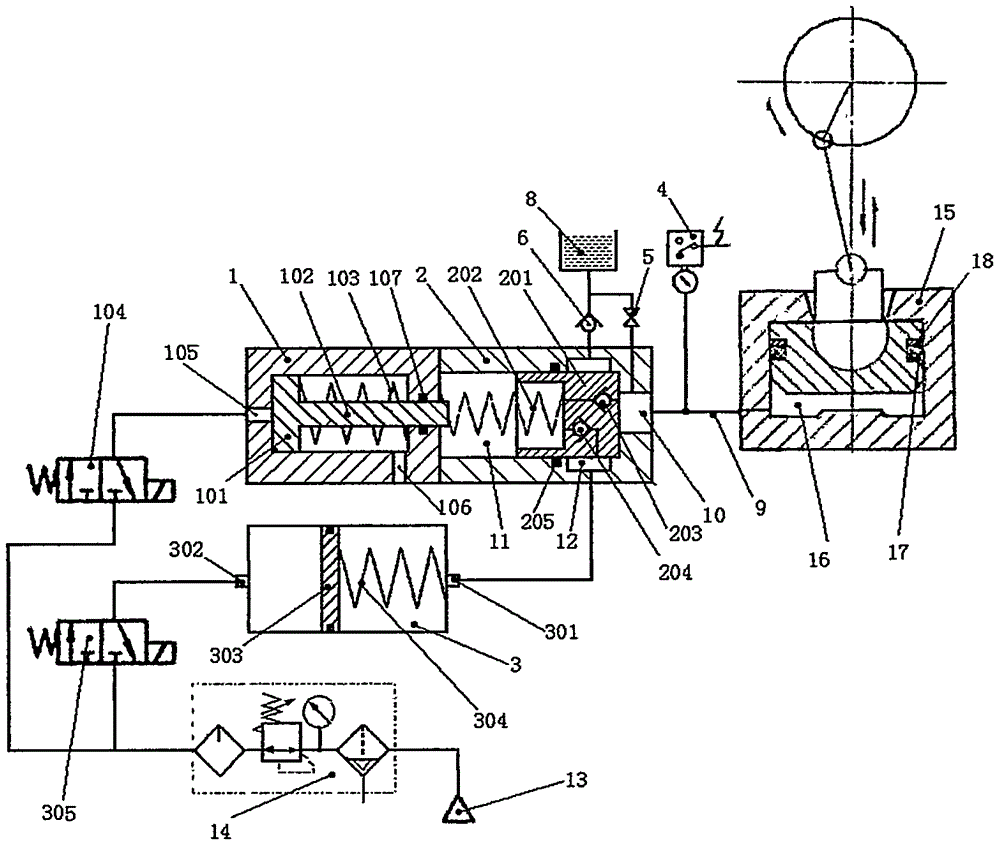

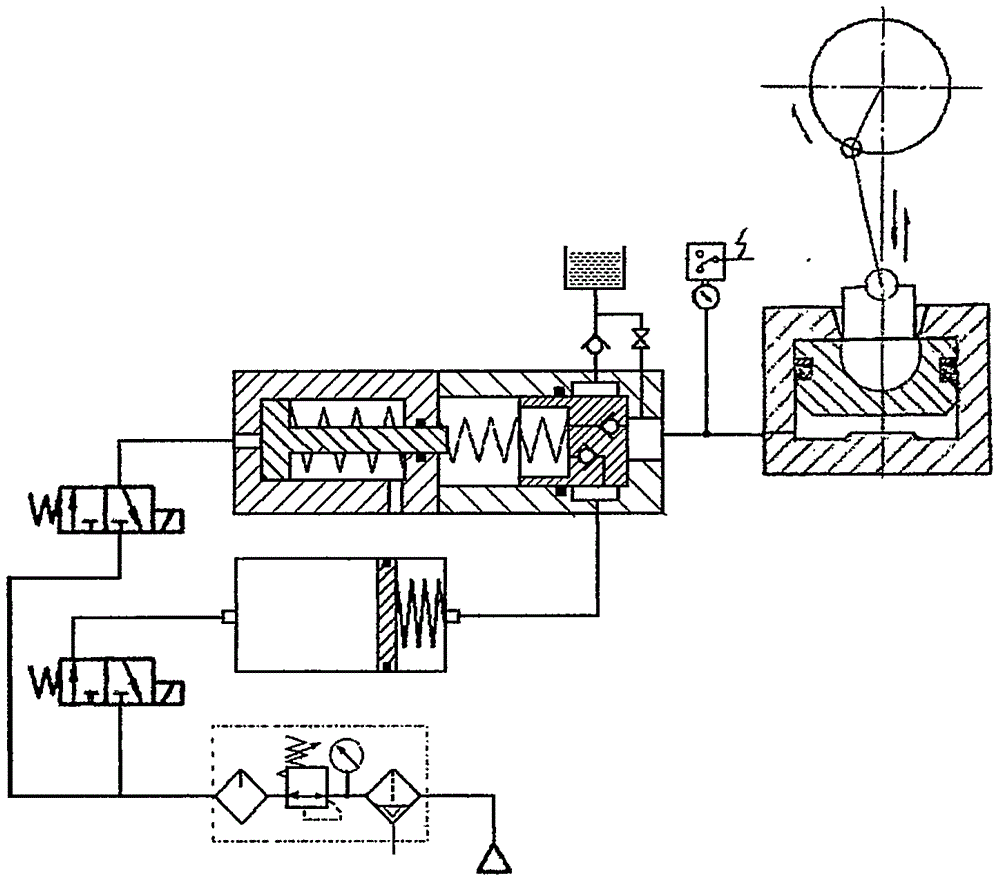

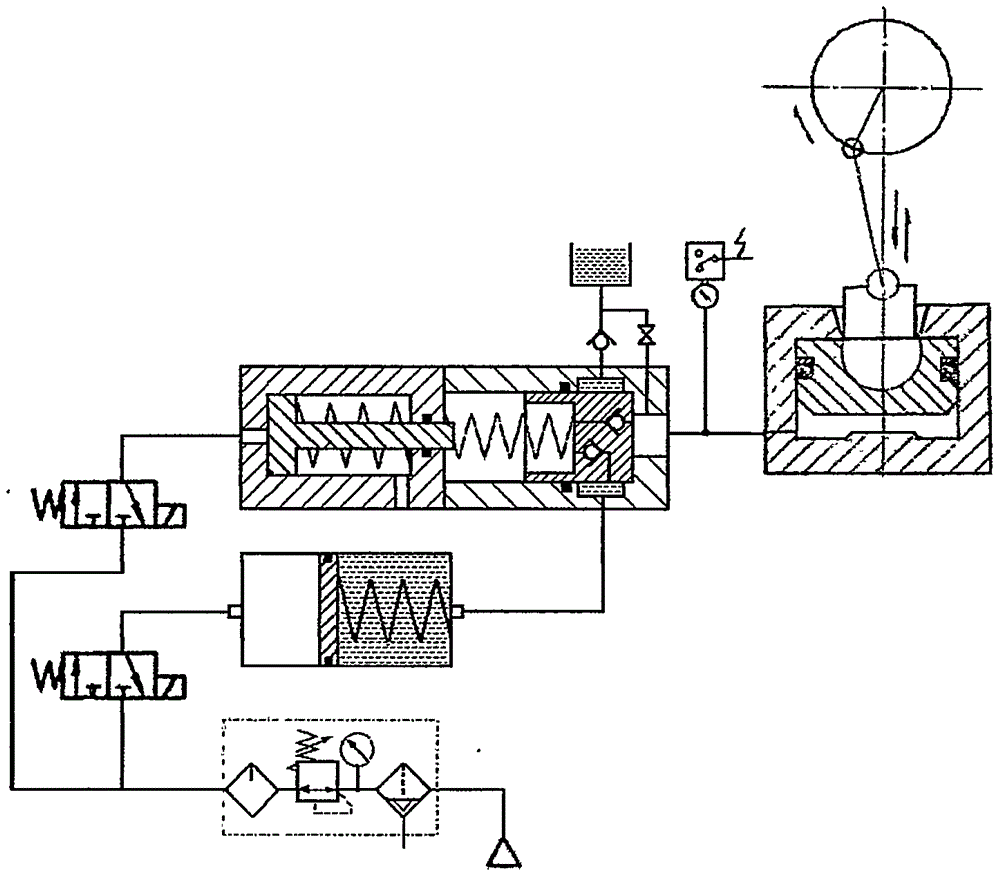

[0035] In order to better understand and implement the present invention, the present invention will be described in detail below in conjunction with the drawings of the first embodiment.

[0036] see figure 1 , the first embodiment of the present invention includes a pneumatic supercharger 1, an overload relief valve 2, a gas spring accumulator 3, a pressure transmitter 4, an exhaust valve 5, an oil suction check valve 6, a solenoid valve ( 104,305), oil tank 8, high-pressure oil pipe 9, filter pressure regulating assembly 14 and air source 13, form a closed circuit with slide block 15 hydraulic cushion 16, take described overload relief valve 2 as the center:

[0037] ①The balance piston 201 is close to the high-pressure chamber 10 under the action of the back pressure spring 202, and its sealing surface isolates the pressure relief chamber 12 from the high-pressure chamber 10; there are two check valves inside the balance piston 201: one check valve 203 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com