Energy-saving and environment-friendly annular track mobile kiln body brick kiln and heat energy recycling method

A circular track, energy saving and environmental protection technology, applied in the field of brick and tile kilns, can solve the problems of large consumption of manpower and material resources, unfavorable promotion and use, high efficiency, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

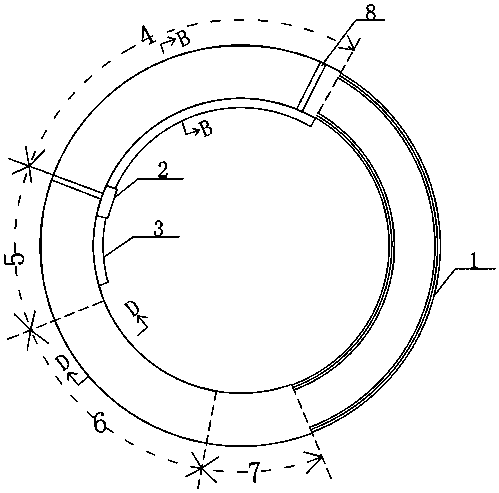

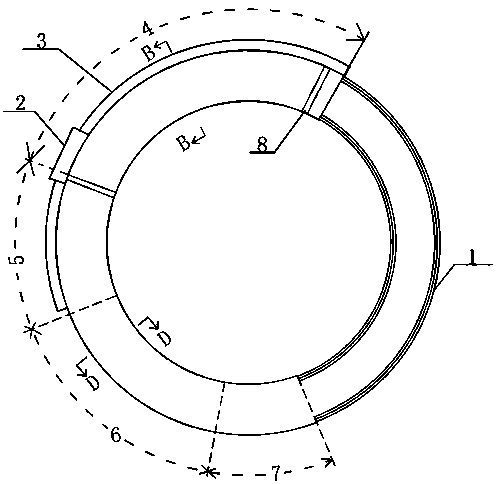

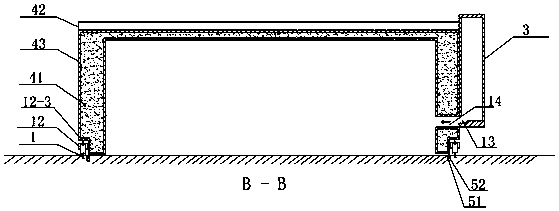

[0090] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 60 , Figure 61 In this embodiment, the energy-saving and environment-friendly circular mobile brick and tile kiln includes a closed circular track 1 connected end to end, a movable kiln body 103 matching the closed circular track 1, and a movable kiln body 103 A certain number of chimneys 15, power driving device, and movable kiln body 103 are divided into drying zone kiln body section 4, preheating zone kiln body section 5, roasting zone kiln body section 6 and cooling zone kiln body section connected in sequence 7. The chimney 15 is set on the top of the kiln body of the kiln body section 4 in the drying zone, and the flue gas dedusting and desulfurization device is set on the top of the kiln body at the flue gas discharge area of the kiln body section 4 in the drying zone. The two ends of the kiln body section 4 are also provided with partitions 8 respectively, an...

Embodiment 2

[0095] Example two, see, Figure 8 , Picture 9 The difference between this embodiment and the first embodiment is that: the top of the drying zone kiln body section 4 in this embodiment is also provided with a certain number of top air ducts 18, and the top air ducts 18 are distributed in the drying radial direction along the track. At the top of the zone kiln body section 4, one end of the top air duct 18 is connected to the side air duct 3 on the side of the movable kiln body, and the other surfaces are closed structures. A certain number of connections with the kiln body are also provided under the top air duct 18 The top branch air duct 19 is connected internally. The side wall of the kiln body section 4 in the drying zone is also provided with a certain number of side branch air ducts 20 communicating with the side air duct 3. In this embodiment, the drying zone The heating structure is added to the kiln body section 4 to further improve the drying efficiency. Other specif...

Embodiment 3

[0096] Example three, see Picture 10 , Picture 11 , Picture 12 , Figure 13 , Figure 14 The difference between this embodiment and the second embodiment is that in this embodiment, the outer surfaces of both side walls of the movable kiln body are provided with side air ducts 3, and the top of the kiln body section 4 in the drying zone is also provided with a certain number of The top air duct 18 is radially distributed along the track at the top of the kiln body section 4 in the drying zone. The top air duct 18 has an open structure alternately at both ends in the radial direction of the annular track, and the other ends are closed structures. The open end surface of the air duct 18 communicates with the side air duct 3 at the open end surface. A certain number of top branch air ducts 19 connected to the inside of the kiln body are also provided under the top air duct 18, and the kiln body section 4 in the drying zone A certain number of side branch air ducts 20 communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com