Gradient thermal shock test device based on halogen lamp cofocal heating technology

A test device, a halogen lamp technology, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of long time consumption, serious noise pollution, low efficiency, etc., and achieve the goal of overcoming high operating costs, saving experimental costs, and eliminating potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

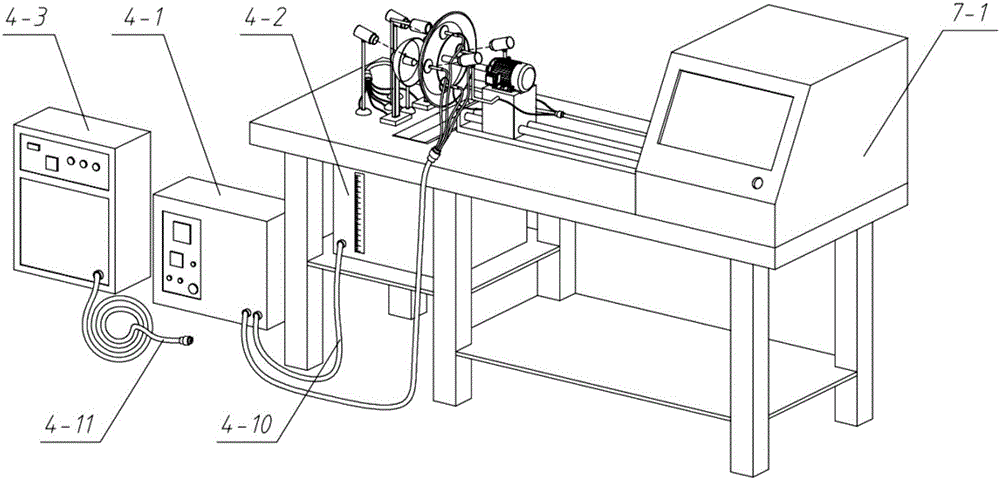

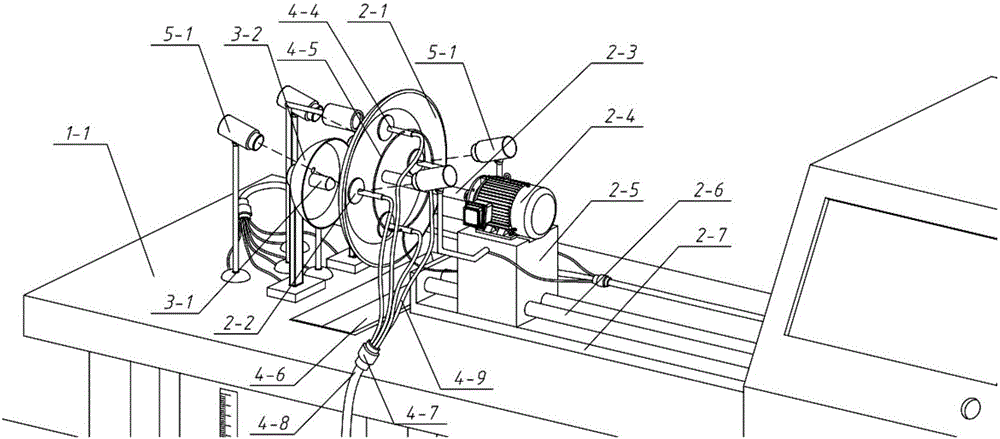

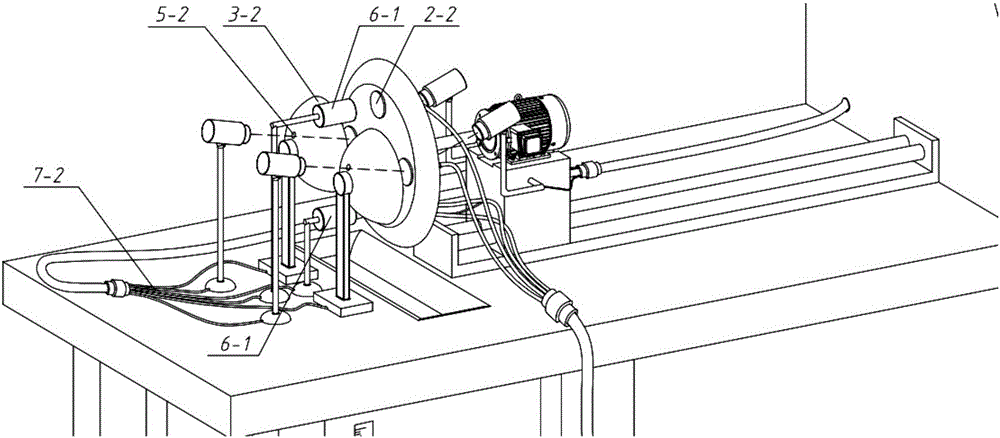

[0041] Such as figure 1 , 2 As shown in and 3, a gradient thermal shock test device based on halogen lamp confocal heating technology of the present invention is composed of 6 parts: test device base, slidable and rotating clamping system, halogen lamp confocal heating system, cooling system , temperature measurement system, digital image acquisition system and integrated control system.

[0042] The test device base is mainly composed of stainless steel base, which is mainly used to fix the slidable and rotating clamping system, the halogen lamp confocal heating system, the temperature measurement system, the digital image acquisition system and the integrated control system.

[0043] The slidable rotary clamping system is mainly composed of ceramic clamping plate 2-1, sample 2-2, metal rotating shaft 2-3, small motor 2-4, moving slider 2-5, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com