Oil field sludge multicomponent testing method

A test method and technology for oilfield sludge, applied in the direction of removing a certain component and weighing, etc., can solve the problems of untestable wax content, great differences in physical and chemical properties, affecting the speed of testing, etc. The effect of avoiding suction filtration loss and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

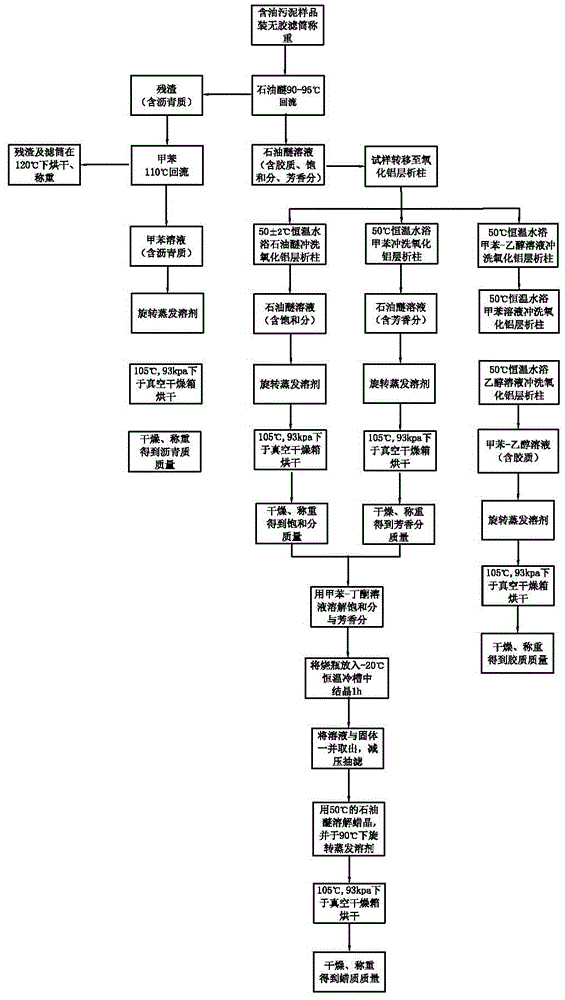

[0043] like figure 1 As shown, extracting 5 parts of sludge samples with a quality of 8 grams from different regions of a certain oil field carries out the test of each component according to the oilfield sludge multi-component test method of the present invention, specifically including the following process:

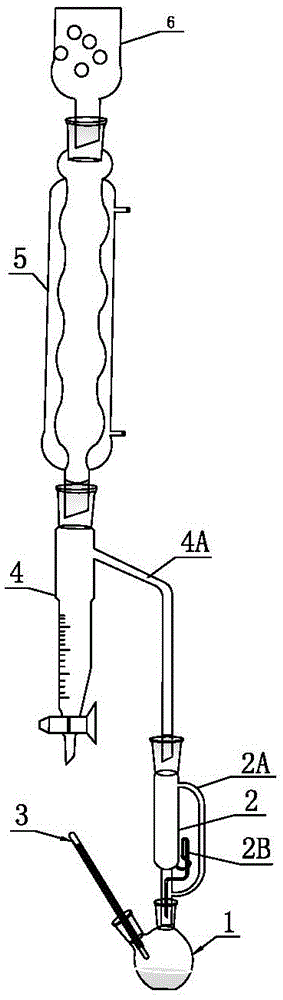

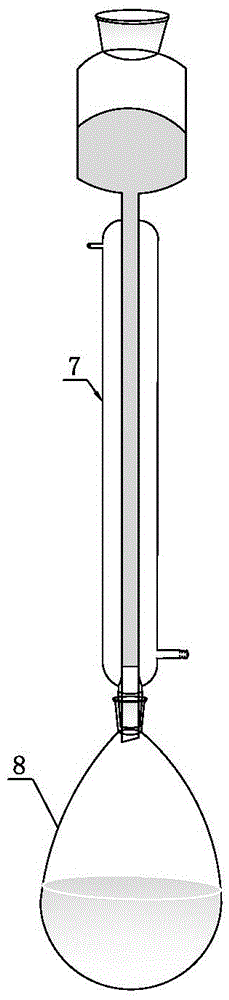

[0044] (1) Put each sample into five non-adhesive filter cartridges with constant weight, and mark them as samples No. 1, 2, 3, 4 and 5 respectively, and package them with a mass of m 筒 In the rubber-free filter cartridges, the quality of each filter cartridge is as described in Table 1, and then the corresponding glue-free filter cartridges were placed in the extraction devices numbered 1, 2, 3, 4, and 5 from sample No. 1 , and respectively use petroleum ether extractant with a boiling range of 90-95°C to conduct heating and reflux extraction at 90±3°C until the extract is clear, and then continue to reflux for 1h. Wherein the extraction device structure in this step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com