Photoelectric panel and laser power supply equipment

A photoelectric panel and laser power supply technology, applied in photovoltaic power generation, photovoltaic power stations, circuits, etc., can solve the problems of large cable consumption, burning of electrical equipment, high cost, etc., and achieve high-efficiency photoelectric conversion, protection of equipment operation, and stable power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

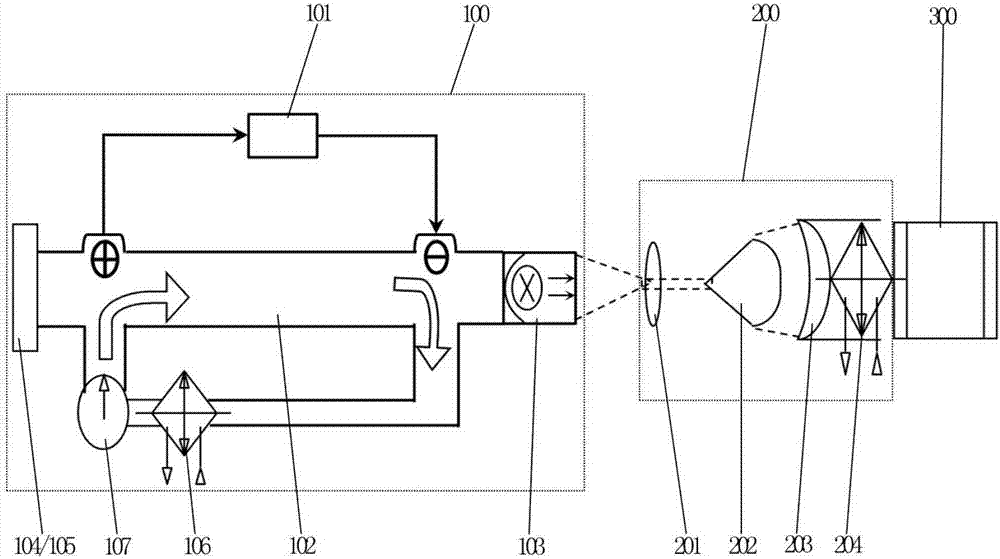

Image

Examples

Embodiment 2

[0040] This embodiment is the same as Embodiment 1, the only difference lies in the material of the photovoltaic panel.

[0041] The material of the photovoltaic cell board is a phosphide metal composite material. In this embodiment, the composition of the phosphide metal composite material is composed of the following elements by mass percentage: 5-15% phosphorus, 5-12.5% copper, 25-35% selenium, 13 - 25% indium 23-40% gallium, the metal phosphide composite material is a composite comprising copper phosphide, copper, selenium phosphide, selenium, indium phosphide, indium, gallium phosphide, gallium and phosphorus.

[0042] Preferably, the metal phosphide composite material consists of the following elements in mass percentage: 15% phosphorus, 12.5% copper, 35% selenium, 13% indium and 24.5% gallium.

[0043] Optionally, the composition of the metal phosphide composite material consists of the following elements by mass percentage: 5% phosphorus, 5% copper, 25% selenium, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com